Organic/Inorganic Composite Electrolyte and Electrochemical Device Prepared Thereby

a technology of composite electrolyte and electrochemical device, which is applied in the direction of cell components, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of battery quality degradation and battery energy density drop per unit weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples [UNK]

EXAMPLES 1˜3

Example 1

1-1. Preparation of Alumina Porous Inorganic Particles

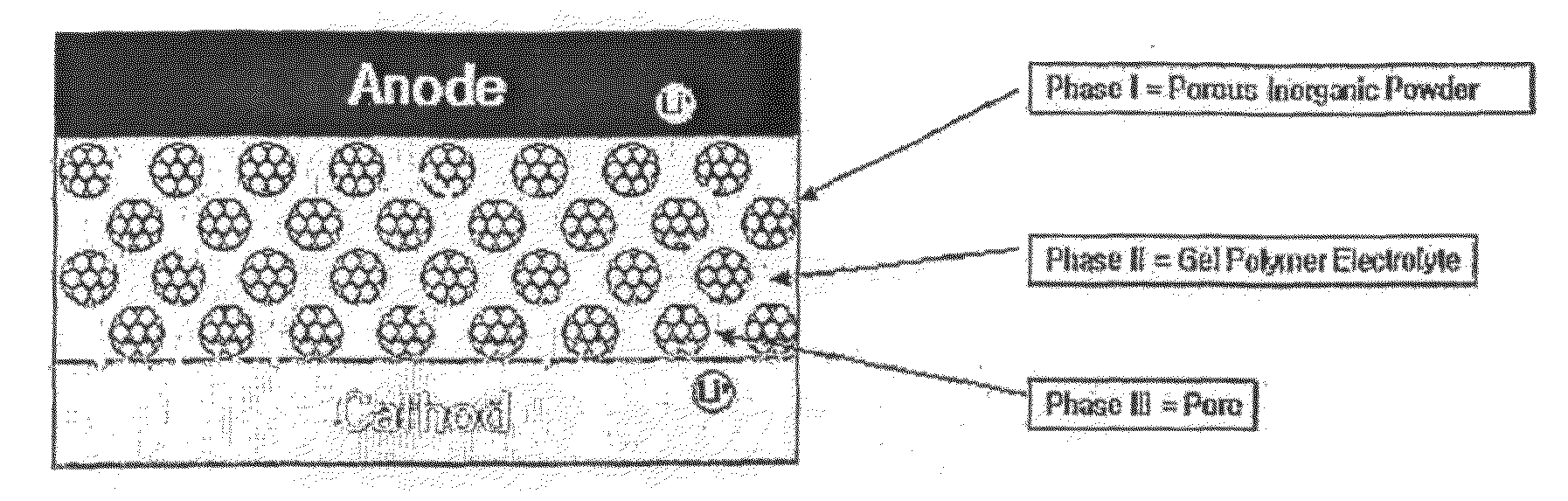

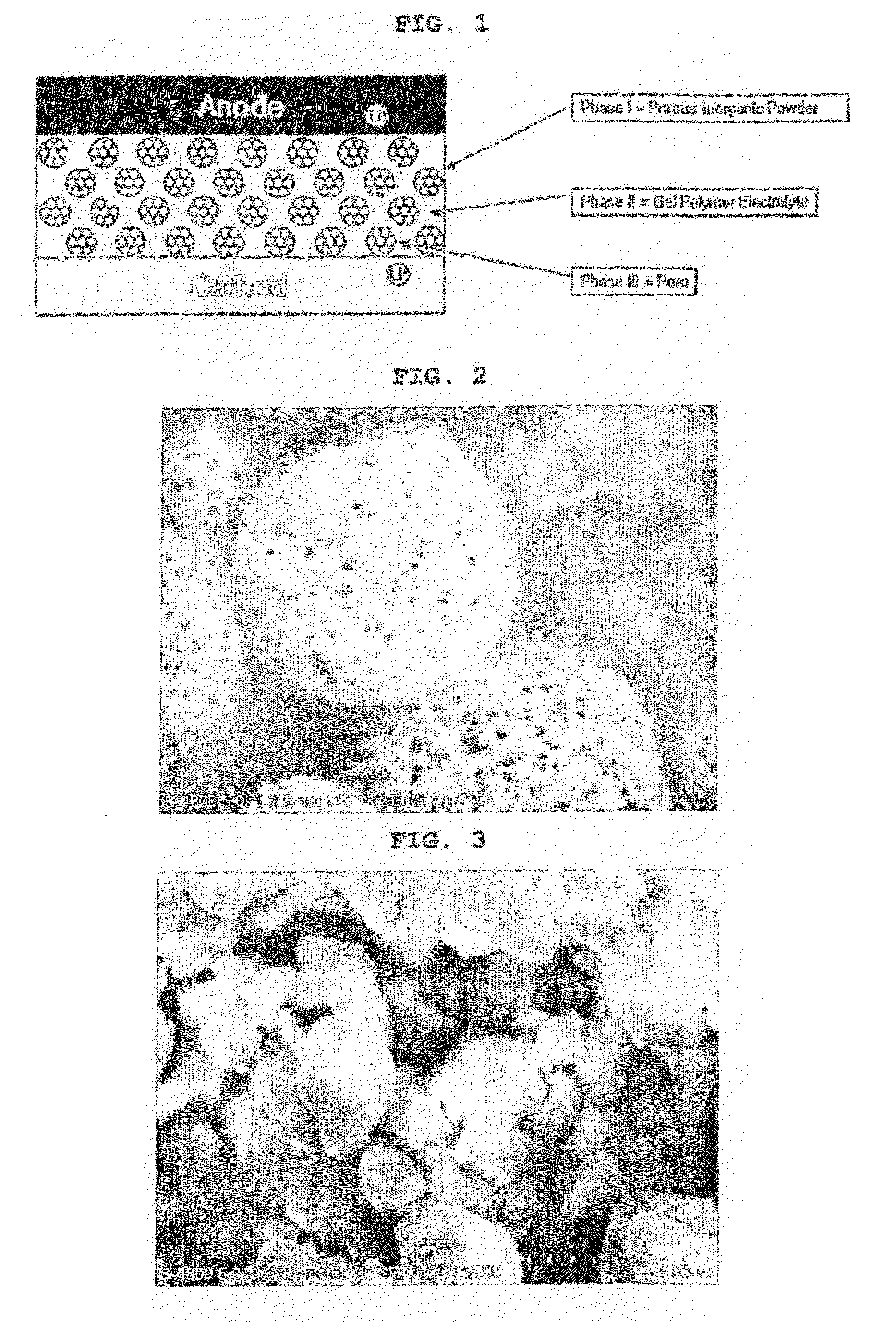

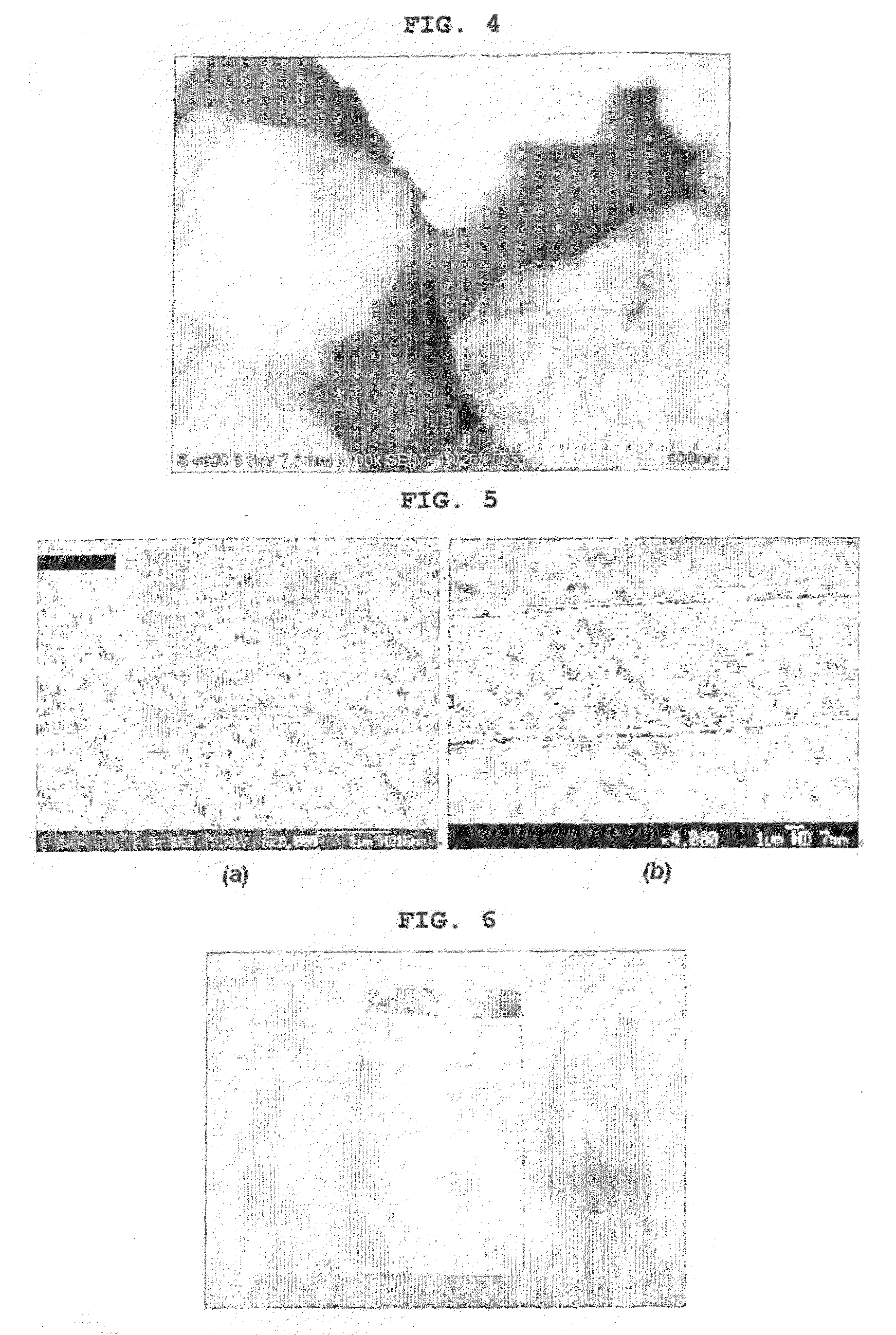

[0081]Aluminum nitrate, an alumina precursor compound, was dissolved in distilled water as a solvent to a concentration of 0.2M. After aluminum nitrate was completely dissolved in distilled water, preliminarily formed polystyrene beads having a diameter of 100 nm was added to the solution in an amount of 3 parts by weight based on the weight of alumina to be prepared, and the mixture was thoroughly agitated. FIG. 8 is a photographic view of the polystyrene beads taken by SEM. The precursor solution obtained as described above was introduced into a spray pyrolysis system to provide porous alumina inorganic particles. FIGS. 2 and 8 are photographic views of the porous alumina particles taken by SEM.

1-2. Manufacture of Electrode Comprising Organic / Inorganic Composite Porous Coating Layer

[0082]To N-methyl-2-pyrrolidone (NMP) as a solvent, 96 wt % of carbon powder as an anode active material, 3 wt % of PVdF (polyv...

example 2

[0088]Example 1 was repeated to provide an electrode comprising an organic / inorganic composite porous coating layer (PVdF-HFP / porous Al2O3) and a lithium secondary battery using the same, except that PVDF-HFP having a solubility parameter of 22˜30 MPa1 / 2 was used instead of PVDF-CTFE. After measuring the pore size and porosity by using a porosimeter, the organic / inorganic composite porous coating layer formed on the electrode had a pore size of 0.51 μm and a porosity of 62%.

example 3

[0089]Example 1 was repeated to provide an electrode comprising an organic / inorganic composite porous coating layer (PVdF-CTFE / TiO2) and a lithium secondary battery using the same, except that porous Al2O3 powder was substituted with porous TiO2 powder having the same pore size and porosity as porous Al2O3 powder. After measuring the pore size and porosity by using a porosimeter, the organic / inorganic composite porous coating layer formed on the electrode had a pore size of 0.37 μm and a porosity of 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com