Process for manufacturing monolithic all-solid-state battery

An all-solid-state battery and battery technology, applied in battery manufacturing, electrode manufacturing, impregnation manufacturing, etc., can solve problems such as deterioration, inability to produce all-solid single-chip three-dimensional battery assemblies, and cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

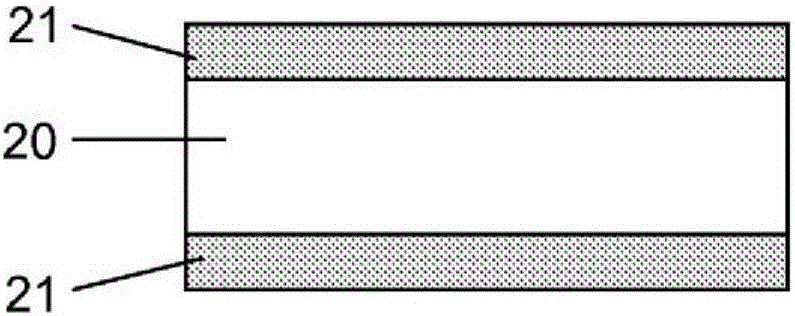

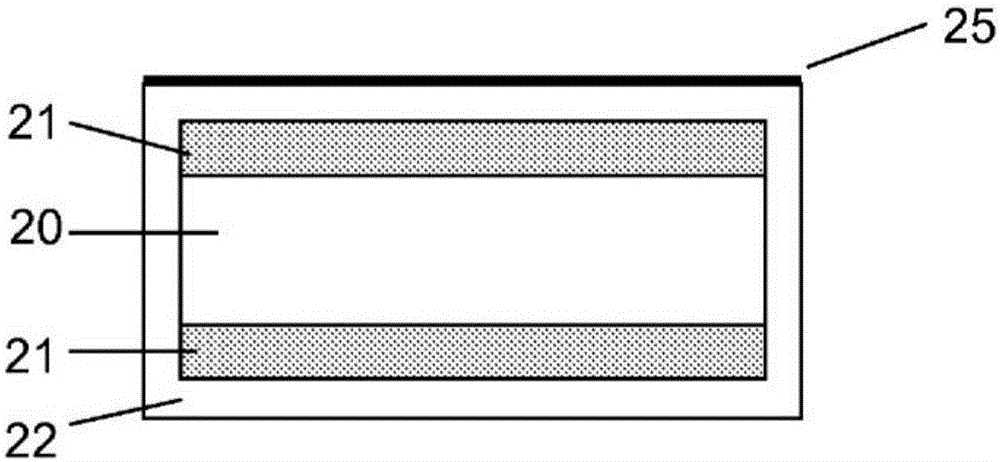

[0171] Example 1 : Ni / Li 4 Ti 5 O 12 / LiPON / LiCoO 2 / Ni assembly

[0172] a) Prepare the substrate

[0173] A nickel strip having a thickness of 20 μm is provided. An ITO film covered with a Pt film of about 100 nm is deposited on these strips to prevent nickel from diffusing into the electrode material during the heat treatment step. Each of the bars is placed in the support frame to create a rigid structure for supporting the substrate.

[0174] b) Depositing the anode layer / depositing the electrolyte layer on the anode layer

[0175] The anode layer is deposited on the substrate by the sol-gel method. By impregnating the substrate to deposit polyvinylpyrrolidone (PVP), titanium isopropoxide (CH 3 ) 2 CHO) 4 Ti, acetic acid (CH 3 COOH) and lithium isopropanol (Li(OC 3 H 7 )The solution. The molar chemical composition of this solution is Li(OC 3 H 7 ) / ((CH 3 ) 2 CHO) 4 Ti / PVP / CH 3 COOH / i-C 3 H 7 OH=4:5:5:100:100. Next, the first deposition layer was dried and sintered at 700° ...

example 2

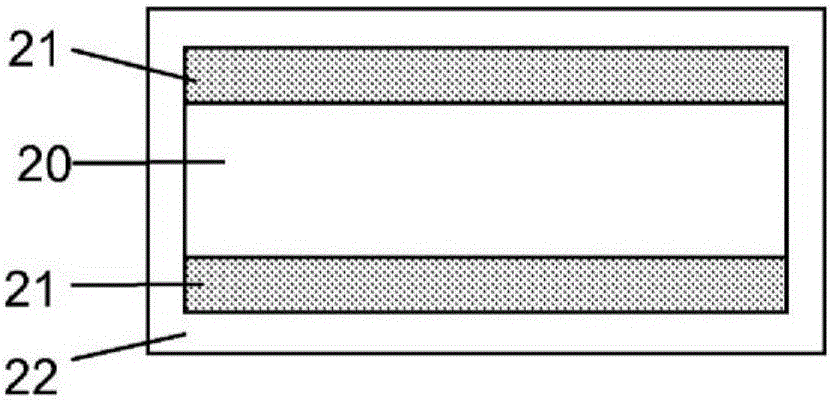

[0184] Example 2 : Ni / Li 4 Ti 5 O 12 / Li 3 Sc 1.6 Al 0.4 (PO 4 ) 3 / LiCoO 2 / Ni assembly

[0185] a) Prepare the substrate

[0186] A nickel strip having a thickness of 10 μm is provided. On these strips, a thin palladium film of about 100 nm is deposited. The strips are placed in the support frame to create a rigid structure for supporting the substrate.

[0187] b) Depositing the anode layer / depositing the electrolyte layer on the anode layer

[0188] The anode layer is deposited on the substrate by the sol-gel method. By impregnating the substrate to deposit polyvinylpyrrolidone (PVP), titanium isopropoxide (CH 3 ) 2 CHO) 4 Ti, acetic acid (CH 3 COOH) and lithium isopropanol (Li(OC 3 H 7 )The solution. The molar chemical composition of this solution is Li(OC 3 H 7 ) / ((CH 3 ) 2 CHO) 4 Ti / PVP / CH 3 COOH / i-C 3 H 7 OH=4:5:5:100:100. Next, the first deposition layer was dried and sintered at 700°C for 1 hour, and then the deposition step was performed by dripping the solution as d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com