Negative active material for rechargeable lithium battery, method of preparing the same, and rechargeable lithium battery including the same

a rechargeable lithium battery and negative active material technology, applied in the direction of electrode manufacturing process, cell components, coatings, etc., can solve the problems of low energy density per unit volume, low density of graphite active material, etc., and achieve excellent coulomb efficiency, rate capability, and cycle life characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

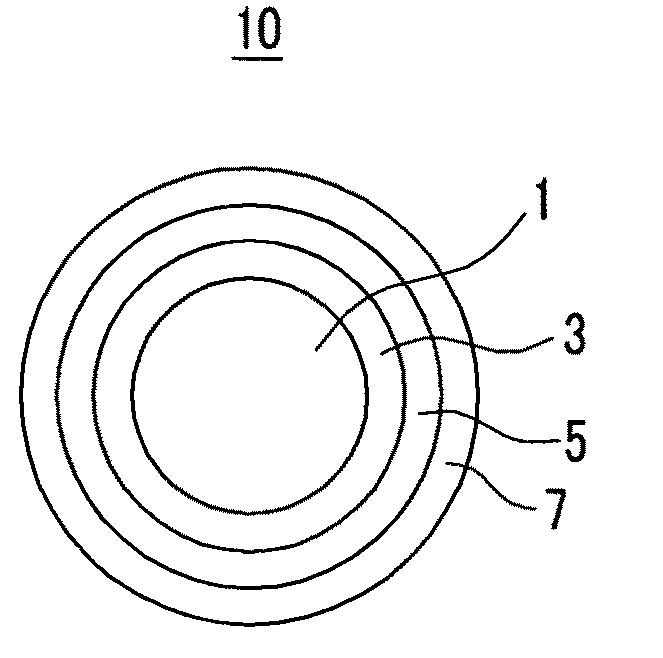

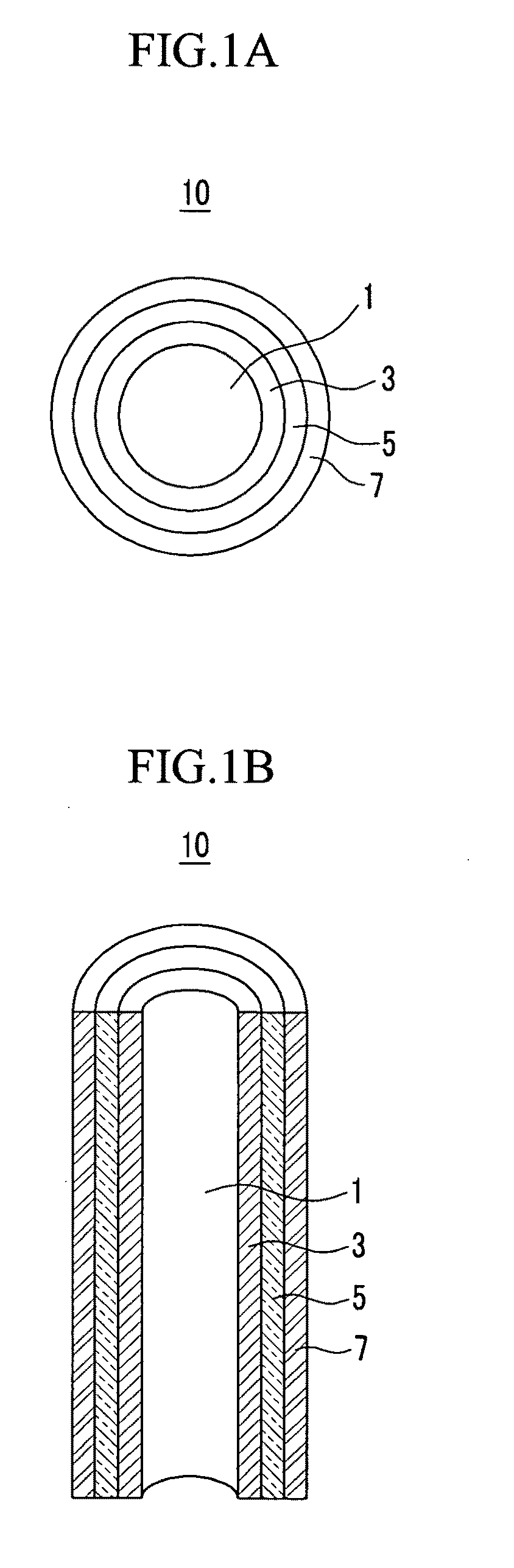

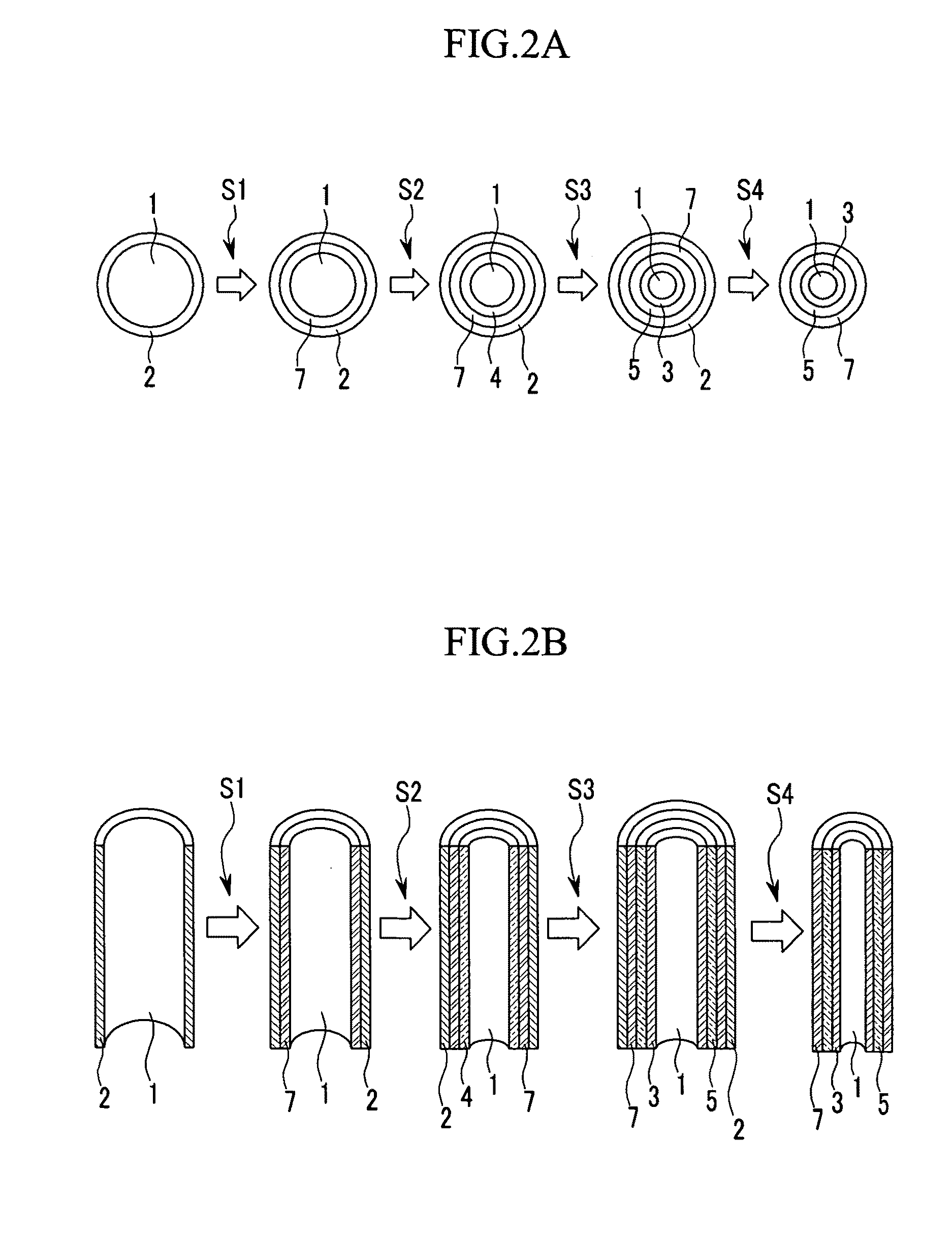

Image

Examples

preparation example 1

Preparation of Silicon Modified with a Butyl Group

[0101]30 g of SiCl4 (purity of 99.999%, Aldrich Co.) was completely mixed with 100 g of 1,2-dimethoxyethane. The mixed solution was decanted with a sodium naphthalide solution and then refluxed at 400° C. for 1 hour. The resulting solution was mixed with 40 ml of a n-butyllithium, a Grignard agent. The mixture was agitated for one night. Herein, the n-butyllithium reacted with SiCl4 and formed silicon modified with a butyl group. Then, the solvent and the naphthalene were removed by heating the mixture under vacuum at 120° C. with a rotating evaporator. In addition, NaCl and LiCl byproducts were removed using an excess amount of n-hexane and water. The final product, silicon modified with a butyl group, was a light yellow viscous gel.

example 1

Preparation of a Negative Active Material for a Rechargeable Lithium Battery

[0102]An alumina (Anodisc, Whatman Co.) template having a hollow part with a 250 nm diameter was immersed in a 0.6M SnCl4 aqueous solution (Aldrich 99%) under an air atmosphere for 4 hours. The alumina template having a hollow part was positioned on a filtering sheet and treated under vacuum for 10 minutes. Next, it was dried at 150° C. for 3 hours and then calcinated at 600° C. under an air atmosphere for 3 hours. Therefore, the alumina template having a hollow part may include an outer layer including SnO2 inside.

[0103]The template including an outer layer including SnO2 inside was immersed in a solution prepared by mixing the silicon gel modified with a butyl group (butyl-capped Si) according to Preparation Example 1 with hexane in a weight ratio of 50:50 for 30 minutes, and then positioned on a filtering sheet and treated under vacuum for 10 minutes. Next, it was dried at 150° C. under vacuum. The immers...

example 2

Preparation of a Negative Active Material for a Rechargeable Lithium Battery

[0104]An alumina (Anodisc, Whatman Co.) template having a hollow part with a 250 nm diameter was immersed in a 0.6M SnCl4 aqueous solution (Aldrich 99%) for 4 hours under an air atmosphere. The alumina template having a hollow part was positioned on a filtering sheet and treated under vacuum for 10 minutes. It was dried at 150° C. for 3 hours and calcinated at 600° C. under an air atmosphere for 3 hours. Thus, an outer layer including SnO2 was formed inside the alumina template having a hollow part.

[0105]The template including a SnO2-containing outer layer inside was immersed in a solution prepared by mixing a silicon gel modified with a butyl group (butyl-capped Si) according to Preparation Example 1 with hexane in a weight ratio of 30:70 for 10 minutes, and then positioned on a filtering sheet and treated under vacuum for 10 minutes. Then, it was dried at 150° C. under vacuum. The immersing and drying proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com