Novel method for preparing lithium ion battery anode ternary material LiCoxNiyMn2O2

A lithium-ion battery, a new method of technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of difficult to precisely control the uniform and synchronous precipitation of various elements, complex liquid phase process conditions, and long mixing time. Realize the effect of environment-friendly production, low cost and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

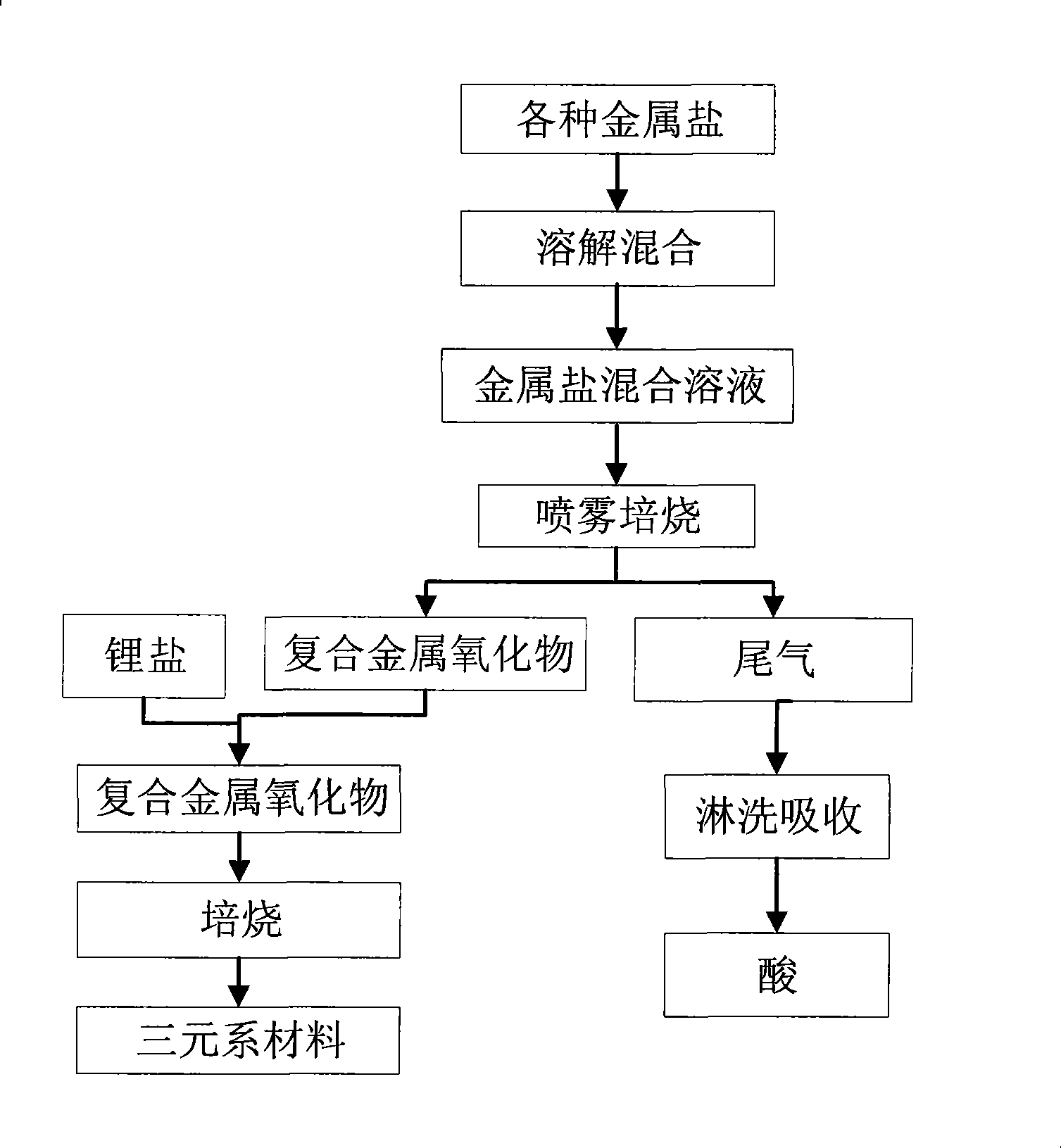

[0018] Embodiment 1, with reference to figure 1 .

[0019] Using cobalt chloride, nickel chloride and manganese chloride as raw materials, according to the ratio of nCo:nNi:nMn=1:1:1, dissolve and mix the samples, and obtain uniformly mixed Co+Ni+Mn of 0.8~3.3mol / L cobalt / nickel / manganese chloride salt solution. The above solution is pressure sprayed under the pressure of 0.2-6MPa to obtain mist droplets, and the mist droplets obtained by spraying are roasted in a dynamic roasting furnace under air or oxygen atmosphere at 600-1000°C to obtain cobalt Nickel manganese composite oxide. The cobalt-nickel-manganese composite oxide obtained by spray roasting is used as a precursor, mixed with lithium carbonate according to n(Co / Ni / Co):nLi=1:1-1.5, and roasted at 700-1000°C for 9-20h to obtain LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 . The tail gas generated during the spray roasting process is rinsed and absorbed to obtain regenerated hydrochloric acid.

Embodiment 2

[0020] Embodiment 2, with reference to figure 1 .

[0021] Using cobalt chloride, nickel chloride and manganese chloride as raw materials, according to the ratio of nNi:nCo:nMn = 8:1:1, dissolving and mixing, to obtain uniformly mixed Co+Ni+Mn of 0.8 ~ 3.3mol / L nickel / cobalt / manganese chloride salt solution. The above solution is pressure sprayed under the pressure of 0.2-5MPa to obtain mist droplets, and the mist droplets obtained by spraying are roasted in a dynamic roasting furnace under an air or oxygen atmosphere at 600-1000°C to obtain cobalt Nickel manganese composite oxide. The cobalt-nickel-manganese composite oxide obtained by spray roasting is used as a precursor, mixed with lithium carbonate according to n(Co / Ni / Co):nLi=1:1-1.5, and roasted at 700-1000°C for 9-20h to obtain LiNi 0.8 co 0.1 mn 0.1 o 2 . The tail gas generated during the spray roasting process is rinsed and absorbed to obtain regenerated hydrochloric acid.

Embodiment 3

[0022] Embodiment 3, with reference to figure 1 .

[0023] Using cobalt chloride, nickel chloride and manganese chloride as raw materials, according to the ratio of nNi:nCo:nMn=4:2:4, dissolve and mix the samples, and obtain uniformly mixed Co+Ni+Mn with a content of 0.8-3.3mol / L nickel / cobalt chloride salt solution. The above solution is pressure sprayed under the pressure of 0.2-6MPa to obtain mist droplets, and the mist droplets obtained by spraying are roasted in a dynamic roasting furnace under air or oxygen atmosphere at 600-1000°C to obtain cobalt Nickel composite oxide. The cobalt-nickel composite oxide obtained by spray roasting is used as a precursor, mixed with lithium hydroxide according to n(Ni / Co / Mn):nLi=1:1-1.5, and roasted at 700-1000°C for 9-20h to obtain LiNi 0.4 co 0.2 mn 0.4 o 2 . The tail gas generated during the spray roasting process is rinsed and absorbed to obtain regenerated hydrochloric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com