Preparation method of ultrafine needle-like wollastonite modified spherical silicon dioxide composite powder

A spherical silica, acicular wollastonite technology, applied in chemical instruments and methods, dyed low molecular organic compound treatment, fibrous fillers, etc. Easy precipitation and other problems to achieve the effect of improving powder dispersion and suspension, improving thermal conductivity, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

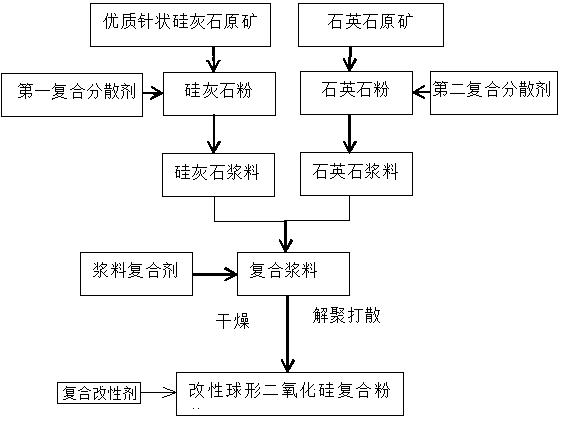

[0037] In this embodiment, a method for preparing ultrafine needle-shaped wollastonite modified spherical silica composite powder, the specific steps are as follows:

[0038] The high-quality acicular wollastonite raw ore and quartz raw ore are respectively self-cleaned, screened, crushed multiple times, dry-grinded, and classified and collected to obtain 400-mesh needle-shaped wollastonite powder and 600-mesh spherical quartz powder. The electron microscope photo of 400 mesh acicular wollastonite powder is as figure 1 Shown.

[0039] The obtained 400 mesh acicular wollastonite powder and water are prepared into a slurry with a solid content of 65-70%, and the first composite dispersant polyethylene glycol fatty acid sodium and lauryl sulfon are added during the slurry configuration process Sodium, the addition amount is 6‰ of the mass of wollastonite powder, in which the ratio of polyethylene glycol fatty acid sodium and sodium lauryl sulfonate is 1:4.

[0040] The obtained 600 mes...

Embodiment 2

[0044] In this example, a preparation method of superfine needle-shaped wollastonite modified spherical silica composite powder, the specific steps are as follows:

[0045] The high-quality acicular wollastonite raw ore and quartz raw ore are respectively self-cleaned, screened, crushed multiple times, dry-grinded, and classified and collected to obtain 400-mesh needle-shaped wollastonite powder and 600-mesh spherical quartz powder.

[0046] The obtained 400 mesh acicular wollastonite powder and water are prepared into a slurry with a solid content of 65-70%, and the first composite dispersant, sodium ethylene glycol fatty acid and dodecyl sulfonic acid are added during the slurry configuration process Sodium, the added amount is 7‰ of the mass of wollastonite powder, in which the ratio of polyethylene glycol fatty acid sodium and sodium lauryl sulfonate is 1:5.

[0047] The obtained 600 mesh quartz powder and water are prepared into a slurry with a solid content of 55-60%. The secon...

Embodiment 3

[0051] In this example, a preparation method of superfine needle-shaped wollastonite modified spherical silica composite powder, the specific steps are as follows:

[0052] The high-quality acicular wollastonite raw ore and quartz raw ore are respectively self-cleaned, screened, crushed multiple times, dry-grinded, and classified and collected to obtain 400-mesh needle-shaped wollastonite powder and 600-mesh spherical quartz powder.

[0053] The 400-mesh acicular wollastonite powder and water are prepared into a slurry with a solid content of 65-70%, and the first composite dispersant polyethylene glycol fatty acid sodium and lauryl sulfon are added during the slurry configuration process Sodium, the addition amount is 8‰ of the mass of wollastonite powder, in which the ratio of polyethylene glycol fatty acid sodium and sodium lauryl sulfonate is 1:6.

[0054] The obtained 600 mesh quartz powder and water are prepared into a slurry with a solid content of 55-60%. The second composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com