Carbon-Coated Silicon Particle Powder as the Anode Material for Lithium Ion Batteries and Method of Making the Same

a lithium ion battery and carbon-coated silicon technology, applied in the field of carbon-coated silicon particles as lithium ion battery anode material, can solve the problems of low relative lithium capacity, high cost of lithium ion batteries using synthetic graphite electrodes, and low efficiency of lithium ion batteries. achieve good powder flowability, high efficiency, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Material Preparation

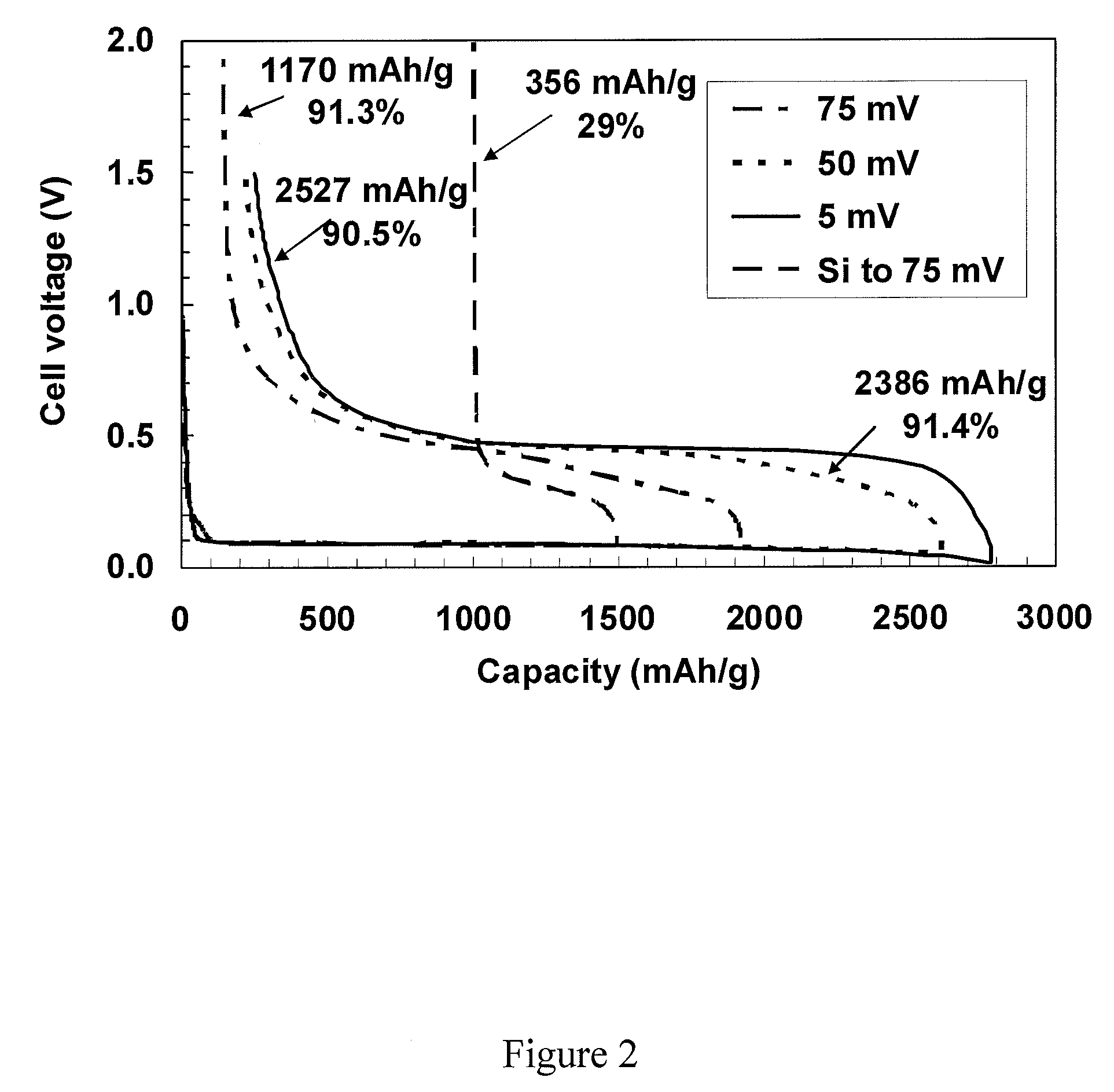

[0057]The silicon powder used in this example had an average particle size of 5 μm (from Johnson Matthey Company). The pitch used for the coating layer was a petroleum pitch from Conoco, Inc. that was approximately 27% insoluble in xylene. The procedure for coating pitch on silicon powder is as follows. First, 20 grams of the silicon powder was mixed with about 100 ml of xylene so that silicon particles were uniformly dispersed in xylene in a glass flask. Concurrently, 14 grams of the pitch was mixed with an equal amount of xylene in another flask so that the pitch was completely dissolved in xylene. Both the solutions were heated to approximately 110° C. and the pitch solution was added into the silicon solution while being continuously mixed. The resulting solution was then heated to 140° C. and continuously stirred for about 15 minutes. The solution was removed from the heater and the solution gradually cooled to ambient temperature (˜25° C.). While the soluti...

example 2

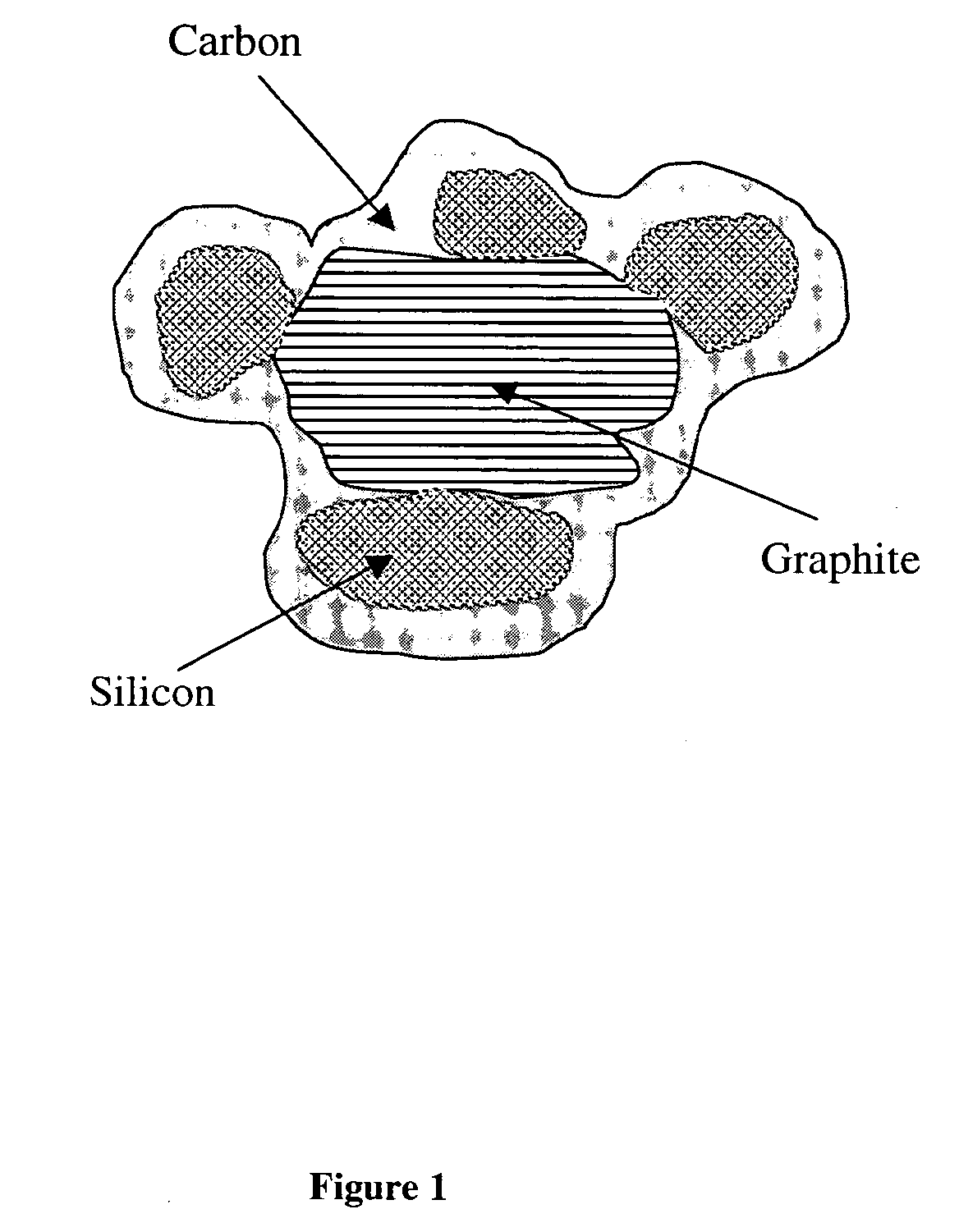

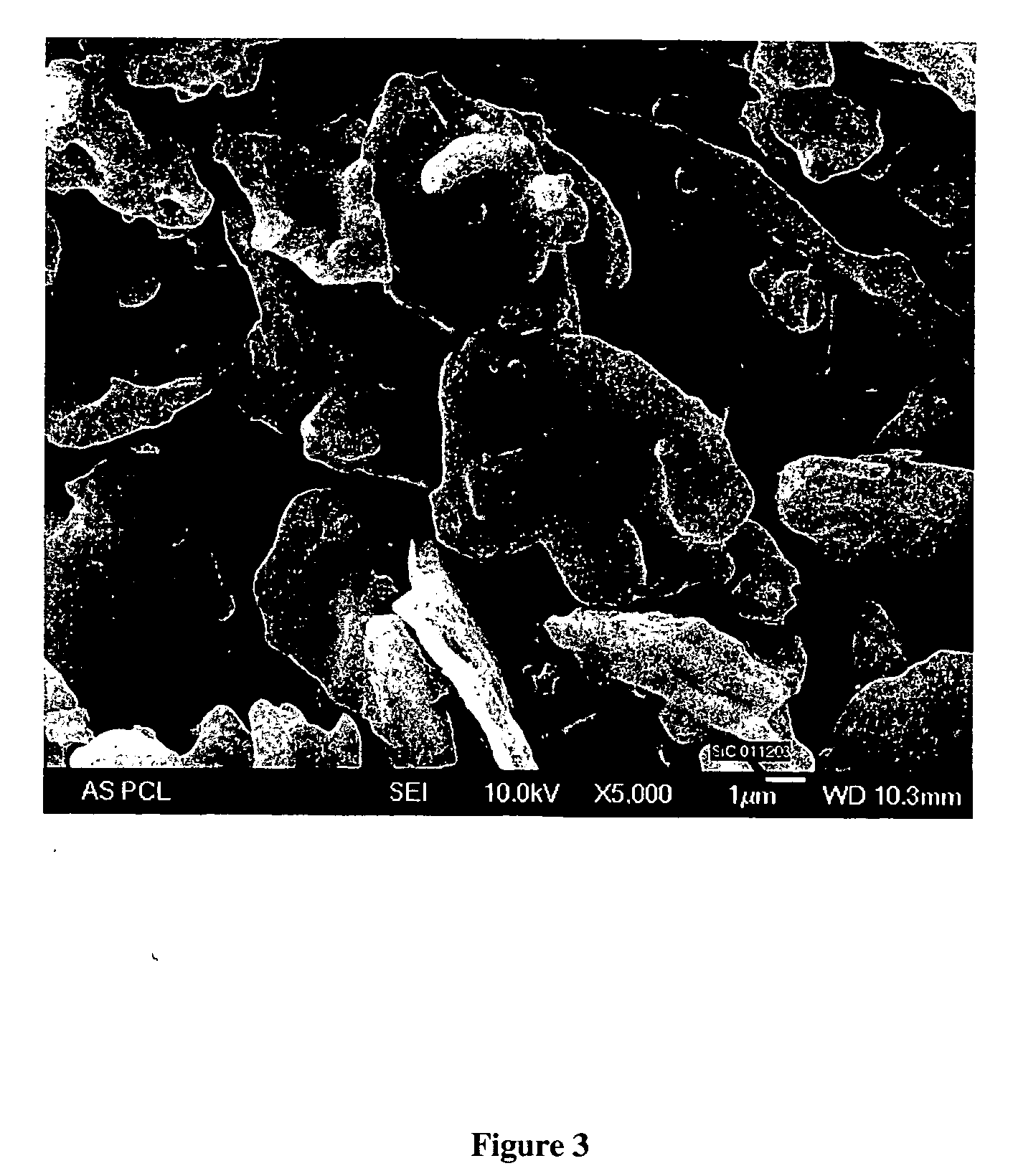

[0064]Twenty grams of a natural flake graphite powder (average particle size 5 μm from China) were coated with 10 wt % petroleum pitch according to the procedure as described in Example 1. The coated graphite powder was stabilized, carbonized, and graphitized at 3000° C. in argon. Concurrently, a silicon powder (average particle size 2 μm, purchased from Johnson Matthey company) was coated with 10 wt % pitch as described in Example 1, stabilized, and carbonized at 1050° C. A mixture of the coated natural graphite powder and the coated silicon powder were combined in the proportion of 6 parts coated graphite and 4 parts of coated silicon powder and coated with 15 wt % solution of the same pitch using the same method. After stabilization in air, the resulting composite powder was carbonized at 1050° C. in nitrogen atmosphere. The resulting graphite / silicon / carbon composite particle powder has morphology as shown in FIG. 3. It can be seen that small silicon particles are embedded in th...

example 3

[0066]Twenty grams of a natural flake graphite powder (average particle size 5 μm from China) were coated with 7 wt % petroleum pitch according to the procedure as described in example 1. The coated graphite powder was stabilized and carbonized at 1200° C. The coated graphite powder was mixed with the coated silicon powder as described in Example 2, in the same proportions. The mixture was then coated with 15 wt % pitch as described in Example 1 and stabilized. Subsequently, the resulting composite particle powder was coated again with 10 wt % pitch, stabilized, and carbonized at 1050° C. in nitrogen atmosphere. The material was evaluated as the anode material for Li-ion batteries in the same manner as described previously. The capacity and efficiency of this material are shown in FIG. 5 for the first five cycles. A significant increase in the rechargeability of the silicon powder is displayed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| particle sizes | aaaaa | aaaaa |

| particle sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com