Device inside a tyre for reducing rolling noise.

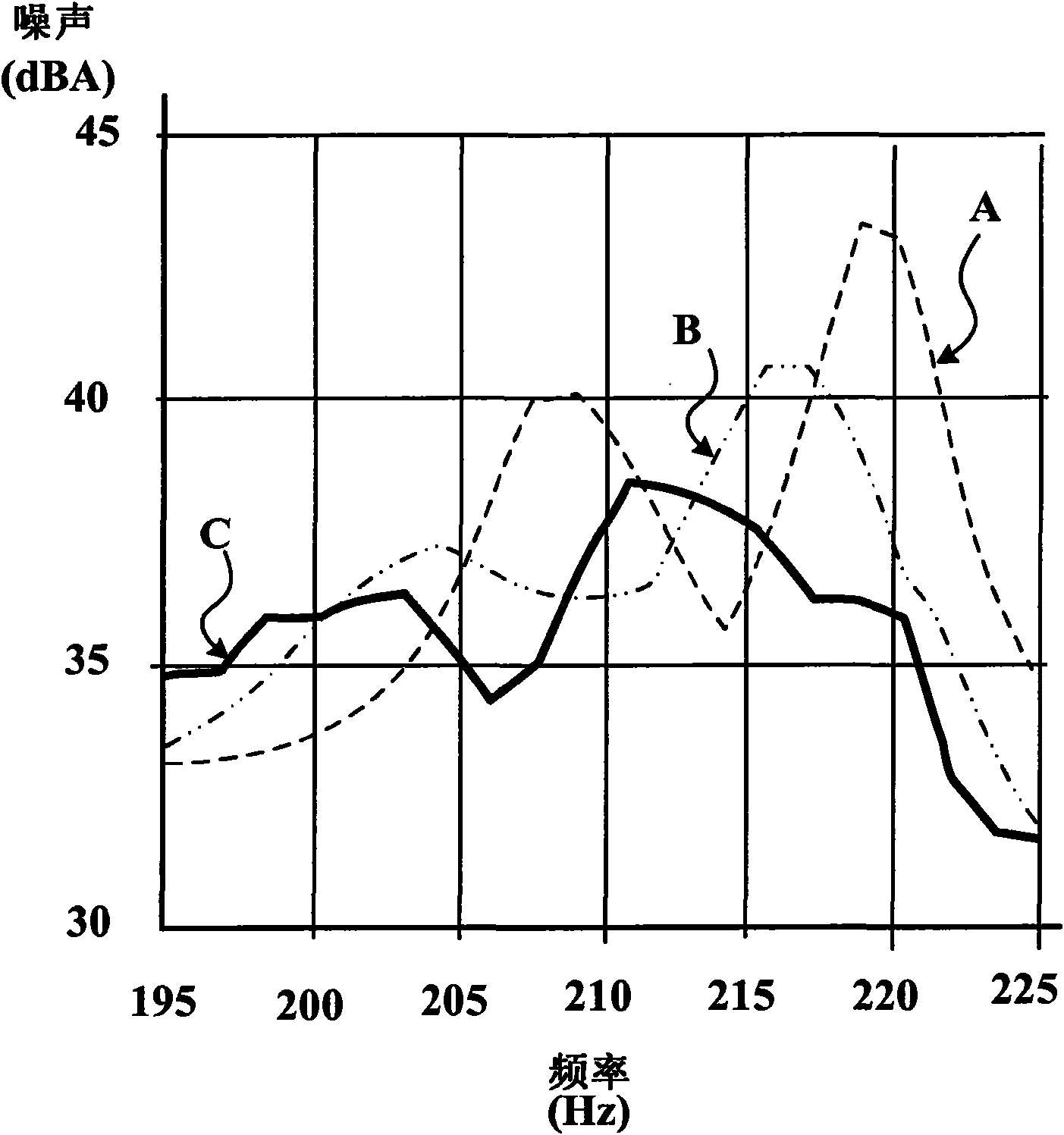

A tire and internal cavity technology, applied to tire parts, pneumatic tires, wheels, etc., can solve problems such as high fiber volume density, and achieve the effect of improving internal cavity noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Description of the drawings

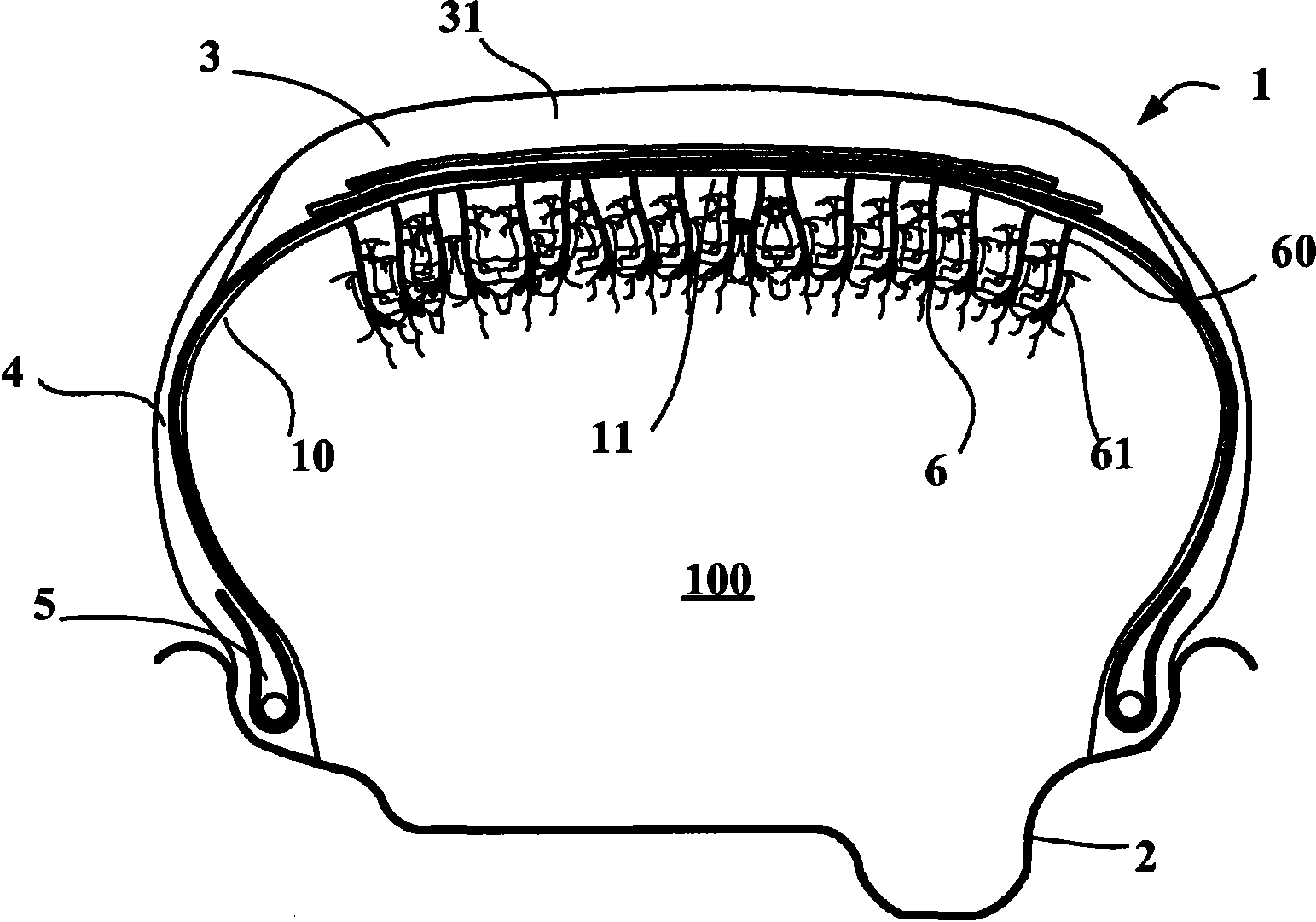

[0030] figure 1 A meridional section (ie a section on a plane containing the axis of rotation of the tyre) through a tire 1 according to the invention mounted on its mounting rim 2 and inflated to its service pressure is shown.

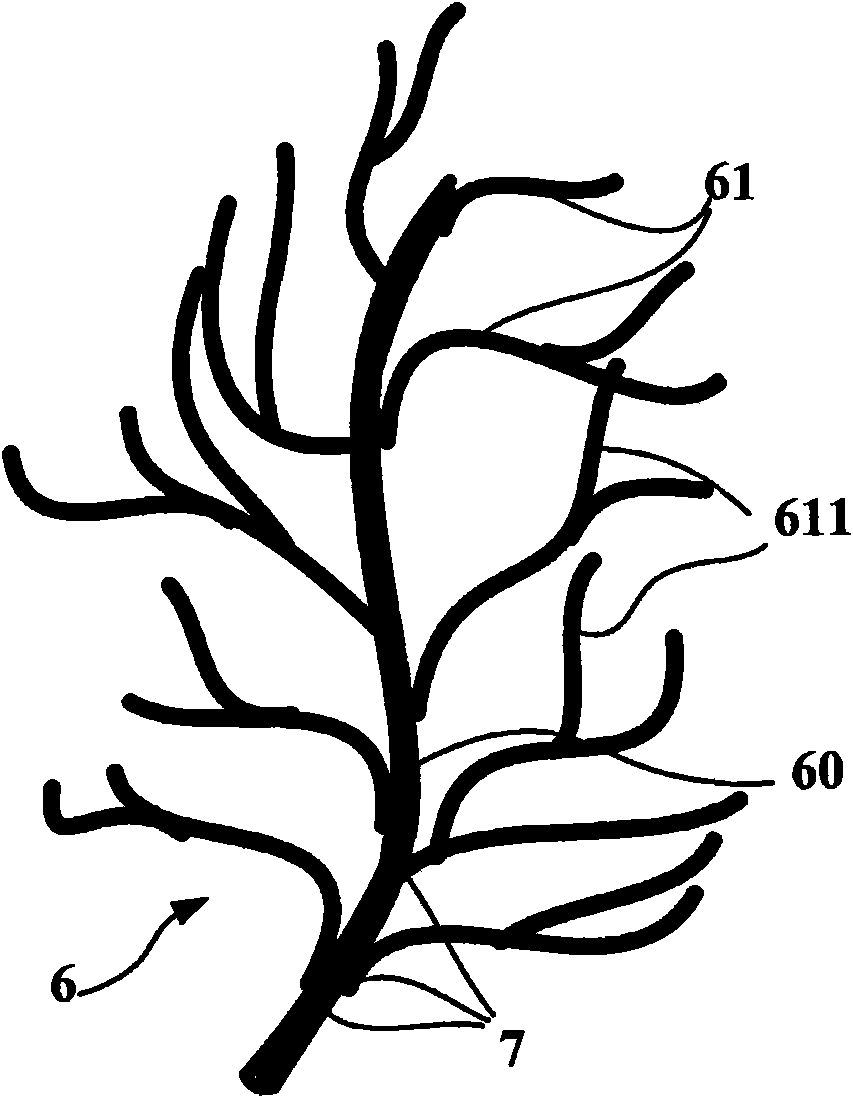

[0031] The tire 1 comprises a crown 3 having, radially on the outside, a tread 31 intended to come into contact with the road surface when the tire is rolling. On each axial side of the crown 3 , the tire comprises sidewalls 4 connecting said crown to beads 5 , the purpose of which is to ensure contact with the mounting rim 2 . The inner wall 10 of the tire defines, together with the outer wall on which the rim 2 is mounted, a cavity 100 for containing gas to be inflated to a given pressure corresponding to the pressure of use of the tire. In order to achieve a good sealing effect, the inner wall 10 of the tire 1 is covered in a known manner with a rubber compound which is airtight with respect to the inflation g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com