Fireproof thermal-insulating plate and preparation process thereof

A fire-proof insulation board and a preparation process technology, which are applied in the directions of heat preservation, fire prevention, building components, etc., can solve the problems of affecting the fireproof performance of the insulation board, the large volume of the insulation board, and the complicated preparation method, and achieve good compressive performance, low cost, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

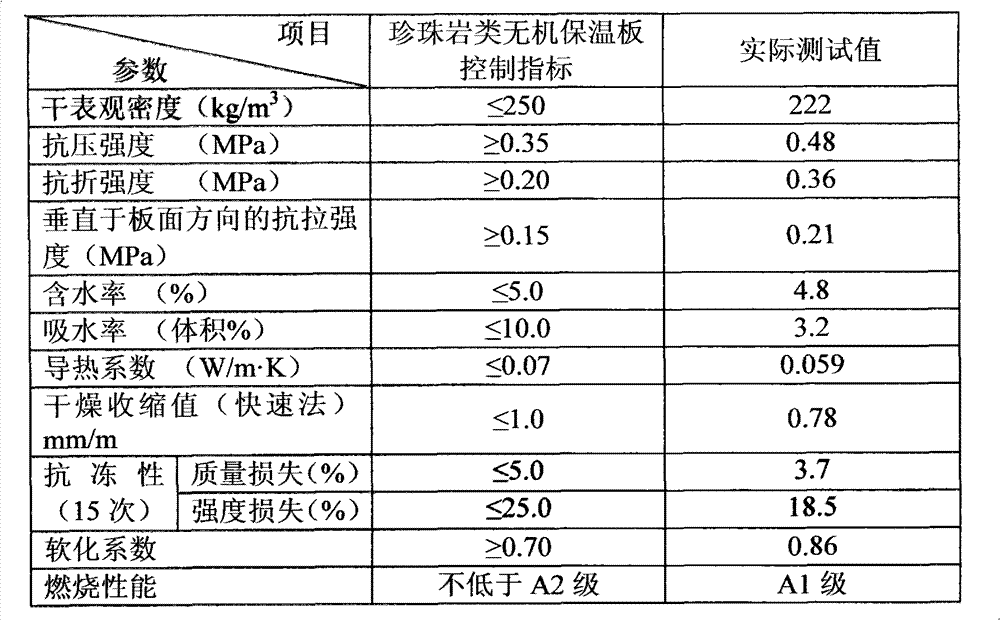

Examples

Embodiment 1

[0020] A fireproof insulation board, comprising the following components in parts by weight: 16 parts of closed-cell expanded perlite with a particle size of 1-5 mm, 3 parts of closed-cell vitrified microbeads with a particle size of 0.1-1.5 mm, 11 parts Parts of binder, 2 parts of water repellent, 0.4 parts of glass fiber and 8 parts of water. The binder is an aqueous solution of a mixture of sodium silicate and calcium silicate or calcium oxide, the weight portion of the mixture in the aqueous solution is 40%, and the weight portion of sodium silicate in the mixture is 30%. The length of the glass fiber is 6-12 mm, and the diameter of the glass fiber is 5-20 μm.

[0021] A preparation process for a fireproof insulation board, comprising the steps of:

[0022] (1) Ingredients: take by weighing 16 parts of closed-cell expanded perlite, 3 parts of closed-cell vitrified microspheres and 0.4 part of glass fiber, and put them into a mixer; weigh 11 parts of binder, 2 parts of wat...

Embodiment 2

[0026] A fireproof insulation board, comprising the following components in parts by weight: 20 parts of closed-cell expanded perlite with a particle size of 1-5mm, 5 parts of closed-cell vitrified microbeads with a particle size of 0.1-1.5mm, 14 Parts of binder, 4 parts of water repellent, 0.6 parts of glass fiber and 12 parts of water. The binder is an aqueous solution of a mixture of sodium silicate and calcium silicate or calcium oxide, the proportion by weight of the mixture in the aqueous solution is 60%, and the proportion by weight of sodium silicate in the mixture is 50%. The length of the glass fiber is 6-12 mm, and the diameter of the glass fiber is 5-20 μm.

[0027] A preparation process for a fireproof insulation board, comprising the steps of:

[0028] (1) Ingredients: take by weighing 20 parts of closed-cell expanded perlite, 5 parts of closed-cell vitrified microspheres and 0.6 part of glass fiber, and enter the mixer; weigh 14 parts of binder, 4 parts of wate...

Embodiment 3

[0032] A fireproof insulation board, comprising the following components in parts by weight: 18 parts of closed-cell expanded perlite with a particle size of 1-5mm, 4 parts of closed-cell vitrified microbeads with a particle size of 0.1-1.5mm, 12 parts Parts of binder, 3 parts of water repellent, 0.5 parts of glass fiber and 10 parts of water. The binder is an aqueous solution of a mixture of sodium silicate and calcium silicate or calcium oxide, the weight portion of the mixture in the aqueous solution is 50%, and the weight portion of sodium silicate in the mixture is 40%. The length of the glass fiber is 6-12 mm, and the diameter of the glass fiber is 5-20 μm.

[0033] A preparation process for a fireproof insulation board, comprising the steps of:

[0034] (1) Ingredients: take by weighing 18 parts of closed-cell expanded perlite, 4 parts of closed-cell vitrified microspheres and 0.5 part of glass fiber, and put them into a mixer; weigh 12 parts of binder, 3 parts of wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com