Cultivation medium

A cultivation medium and medium technology, applied in cultivation, soilless cultivation, fertilizer mixture, etc., can solve the problems of easy breakage, excessive bulk density, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of the medium provided by the present invention

[0018] The medium provided by the present invention consists of the following components in parts by volume:

[0019] Heliotrope, 38-42%; clinoptilolite, 16-21%; diatomaceous earth, 5-7%;

[0020] Akadama soil, 11-16%; Kanuma soil, 6-9%; Kiryu sand, 5-10%;

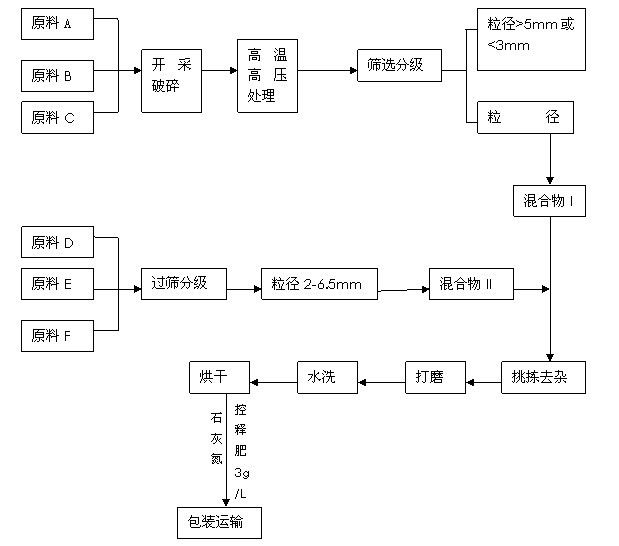

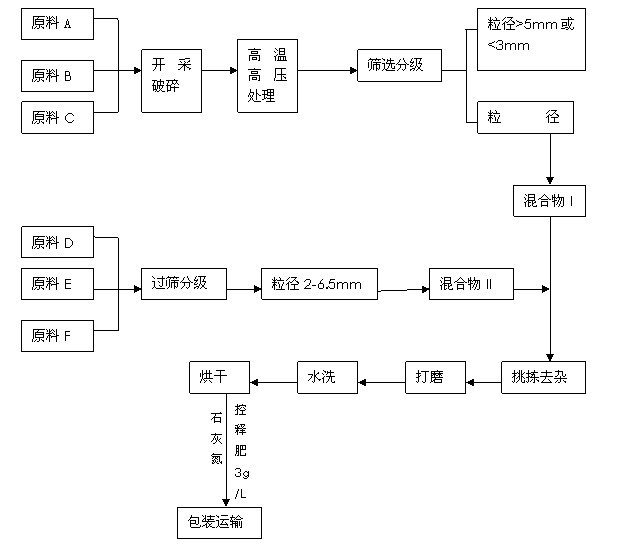

[0021] refer to figure 1 Its preparation process is as follows:

[0022] 1. According to the above ratio, take the raw material A hinata, the raw material B clinoptilolite, and the raw material C Kiryu sand;

[0023] 2. High-temperature and high-pressure treatment of raw materials A, B, and C: through a high-temperature and high-pressure reaction kettle, a double-cycle electric heating furnace is used to heat the kettle. Make the oil temperature in the kettle reach 550±10°C, pressurize to 200±10MPa and keep constant temperature and pressure for 2 to 3 hours, close the reaction kettle and let it cool down slowly until the temperatur...

Embodiment 2

[0029] Take 42L of heliotrope with a particle size of 3-5mm after the high-temperature and high-pressure treatment in step 2 of Example 1, 19L of clinoptilolite, and 10L of Kiryu sand, and mix the three samples evenly for later use. After sieving, the particle size is 2-6.5mm 16L of red jade soil, 5L of diatomaceous earth, and 8L of Kanuma soil, mixed with the aforementioned mixture of hinataite, clinoptilolite, and Kiryu sand, then removed impurities, polished, washed with water, and dried with hot air, and added 0.07g / m of lime nitrogen 2 And long-acting controlled-release fertilizer 3g / L to prepare a mixed medium, which is widely used in plant cultivation medium, characterized by cleanliness, no pests and weed seeds, green and environmental protection, and good fertilizer retention effect.

Embodiment 3

[0031] Take 42L of heliotrope with a particle size of 3-5mm after the high temperature and high pressure treatment in step 2 of Example 1, 21L of clinoptilolite, and 8L of Kiryu sand, and mix the three samples evenly for later use. After sieving, the particle size is 2-6.5mm 16L of red jade soil, 5L of diatomaceous earth, and 8L of Kanuma soil, mixed with the aforementioned mixture of hinataite, clinoptilolite, and Kiryu sand, then removed impurities, polished, washed with water, and dried with hot air, and added 0.07g / m of lime nitrogen 2 And long-acting controlled-release fertilizer 3g / L to make a mixed medium, which is widely used as a garden bottom stone. It is characterized by strong water holding capacity, good air permeability, and no waterlogging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com