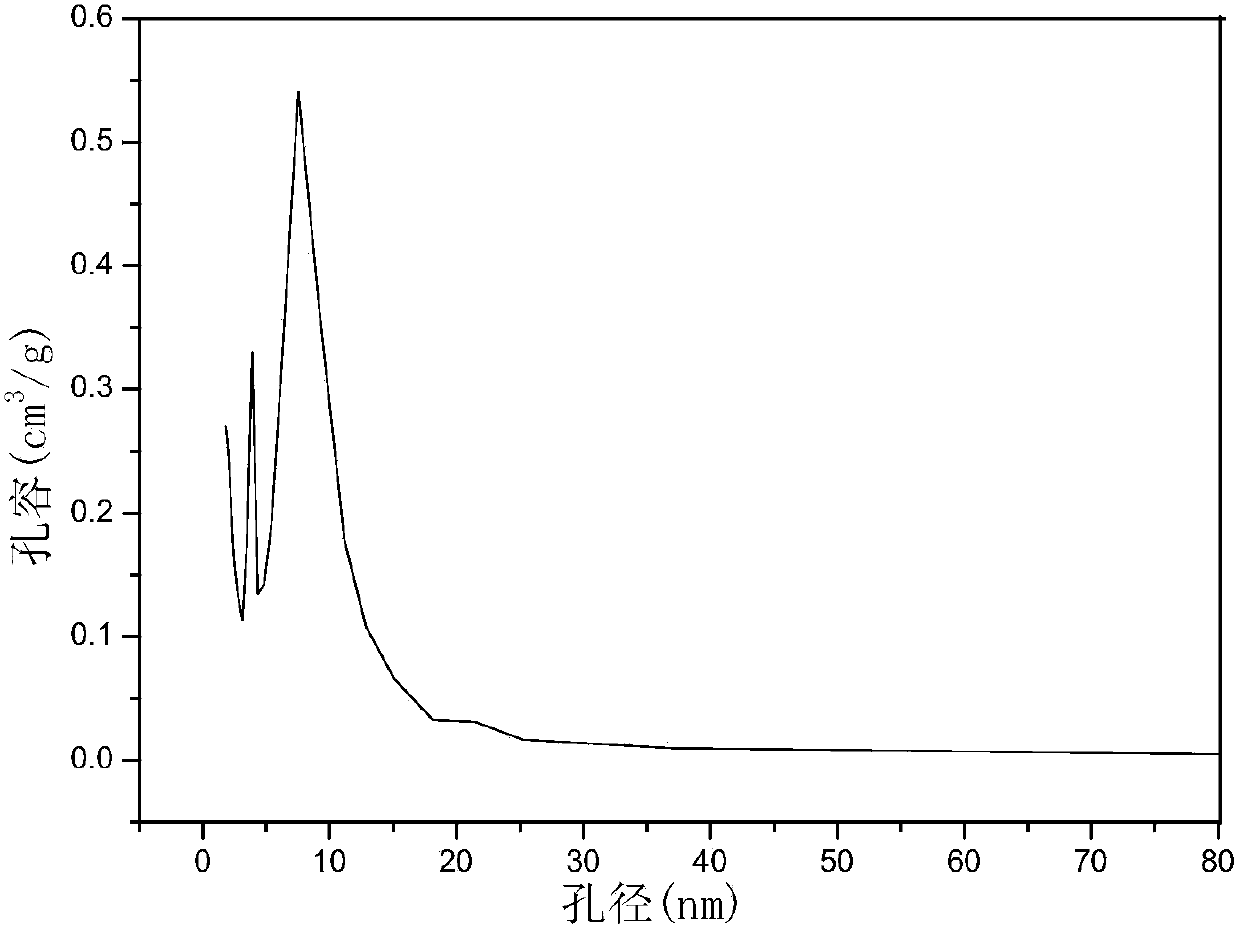

Mesoporous ZSM-5 zeolite, mesoporous ZSM-5 zeolite-loaded metal sulfide catalyst and application

A technology of ZSM-5 and metal loading, which is applied in the application field of hydrocracking reaction, can solve the problems of weak interaction between carbon materials and inorganic species, difficulty in industrial production, and expensive templating agent, and achieve low synthesis cost, Improved catalytic performance and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0045] Take 10ml water glass, add 7.5ml H 2 O, after stirring evenly, add 2.6942g NaOH, wait until it cools down to room temperature, add 2.7ml TPAOH and 8ml DMMC mixture, stir for 1.5h, finally add 13.4ml solution ③, continue stirring for 6h. The molar ratio of Al in the system 2 o 3 : SiO 2 : Na 2 O:TPAOH:H 2 The molar ratio of O is recorded as 1:52:45:3:2050. The mixture was transferred to a reactor and crystallized at 175°C for 84h.

experiment example 2

[0047] Take 10ml water glass, add 19.7ml H 2 O, after stirring evenly, add 2.0077g NaOH, after cooling down to room temperature, add 1.3ml TPAOH and 7ml DMMC mixture, stir for 1.5h, finally add 10.0ml solution ③, continue stirring for 5h. The molar ratio of Al in the system 2 o 3 : SiO 2 : Na 2 O:TPAOH:H 2 The molar ratio of O is recorded as 1:70:50:2:3200. The mixture was transferred to a reactor and crystallized at 180°C for 72h.

experiment example 3

[0049] Take 10ml water glass, add 8.6ml H 2 O, after stirring evenly, add 0.7097g NaOH, after cooling down to room temperature, add the mixture of 1.3ml TPAOH and 2ml DMMC, finally add 10.0ml solution ③, continue to stir for 7h. The molar ratio of Al in the system 2 o 3 : SiO 2 : Na 2 O:TPAOH:H 2 The molar ratio of O is recorded as 1:70:30:2:2100. The mixture was transferred to a reactor and crystallized at 170°C for 48h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com