Dechlorinating agent and preparation method and application thereof

A technology of dechlorination agent and binder, which is applied in the field of dechlorination agent and its preparation, can solve the problems of low chlorine capacity and dechlorination efficiency, achieve the effects of improving chlorine capacity and dechlorination efficiency, stable structure, and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

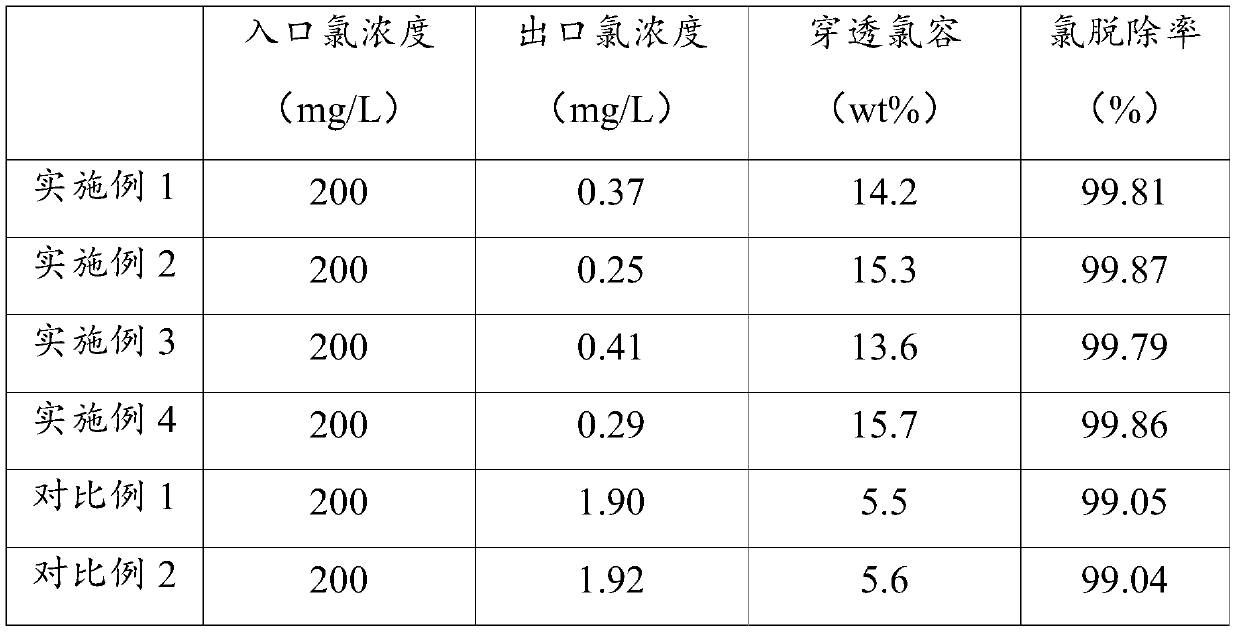

Examples

Embodiment 1

[0035] Present embodiment provides a kind of dechlorination agent, and its preparation method is as follows:

[0036] Dissolving copper nitrate trihydrate, potassium permanganate and polysorbate in water to obtain a mixed aqueous solution, the content of copper nitrate in the resulting mixed solution is 12wt%; the content of potassium permanganate is 20wt%, and the content of polysorbate is 15wt% %;

[0037] Set the specific surface area to 250m 2 / g clay with a specific surface area of 800m 2 / g of HY molecular sieve is mixed evenly to obtain a mixed carrier; wherein, the mass ratio of clay to molecular sieve is 1:80; then the mixed carrier is soaked in the above mixed aqueous solution at 25°C for 6 hours, the The mass ratio is 1:5, and after drying at 25°C for 12 hours, the dechlorination agent precursor can be obtained;

[0038] Mix the above-mentioned dechlorination agent precursor and cellulose sodium powder evenly, and the mass ratio of the dechlorination agent prec...

Embodiment 2

[0041] Present embodiment provides a kind of dechlorination agent, and its preparation method is as follows:

[0042] Dissolving copper nitrate trihydrate, potassium permanganate and polysorbate in water to obtain a mixed aqueous solution, the content of copper nitrate in the resulting mixed solution is 10wt%; the content of potassium permanganate is 30wt%, and the content of polysorbate is 10wt% %;

[0043] Set the specific surface area to 100m 2 / g clay with a specific surface area of 1000m 2 / g of β boiling molecular sieves are mixed evenly to obtain a mixed carrier; wherein, the mass ratio of clay to molecular sieve is 1:50; then the mixed carrier is immersed in the above mixed aqueous solution at 50°C for 10 hours, and the mixed carrier and the mixed aqueous solution The mass ratio is 1:8, and after drying at 50°C for 6 hours, the dechlorination agent precursor is obtained;

[0044]Mix the above-mentioned dechlorination agent precursor and aluminum sol evenly, the ma...

Embodiment 3

[0047] Present embodiment provides a kind of dechlorination agent, and its preparation method is as follows:

[0048] Dissolve copper nitrate trihydrate, potassium permanganate and polysorbate in water to obtain a mixed aqueous solution, the content of copper nitrate in the resulting mixed solution is 20wt%; the content of potassium permanganate is 8wt%, and the content of polysorbate is 8wt% %;

[0049] Set the specific surface area to 500m 2 / g clay with a specific surface area of 100m 2 The ZSM-5 molecular sieve / g is mixed uniformly to obtain a mixed carrier; wherein, the mass ratio of clay to molecular sieve is 1:100; then the mixed carrier is immersed in the above mixed aqueous solution at 30°C for 1 hour, and the mixed carrier and the mixed The mass ratio of the aqueous solution is 1:10, and after drying at 30°C for 1 hour, the dechlorination agent precursor is obtained;

[0050] Mix the above-mentioned dechlorination agent precursor and silica sol evenly, the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com