Blast furnace coal gas dechlorinating agent, preparation method of dechlorinating agent and dechlorinating method thereof

A technology for blast furnace gas and dechlorination agent, which is applied in combustible gas purification, combustible gas purification/transformation, and selection of absorbing solid gas purification, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

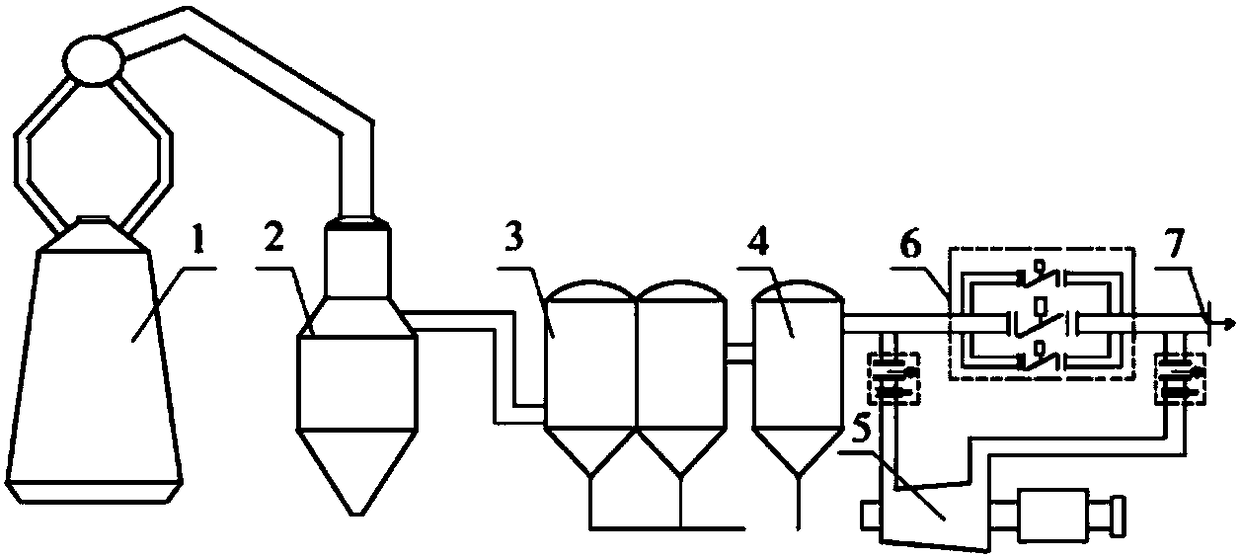

Method used

Image

Examples

preparation example Construction

[0048] The invention provides a blast furnace gas dechlorination agent, a preparation method thereof and a dechlorination method, which have low cost and excellent performance and are suitable for the blast furnace gas dechlorination field.

[0049] The blast furnace gas dechlorination agent provided by the invention is a calcium-based dechlorination agent; calcium carbonate (CaCO 3 ) as an active component, knead calcium carbonate, a binder and a certain amount of water together, then extrude, keep healthy overnight in a natural environment, and then dry at a higher temperature; the blast furnace gas dechlorination The strength of the agent is above 80N / cm; the blast furnace gas dechlorination agent can be washed with water during use, and the strength of the blast furnace gas dechlorination agent after water washing is above 50N / cm. The drying at a higher temperature is specifically drying at a temperature of 120° C. for 3 to 12 hours; the binder uses clay minerals that will...

Embodiment 1

[0056]Add heavy calcium carbonate and diatomaceous earth binder to the kneader respectively, the mass fraction of calcium carbonate in the dechlorination agent is 30%, then add a certain amount of water, fully knead, the amount of water added depends on the water absorption of the raw materials, and then Extruded into a cylindrical shape, kept in a natural environment overnight, and dried at 120°C for 3 hours to make a finished dechlorination agent with a strength of 80.17N / cm.

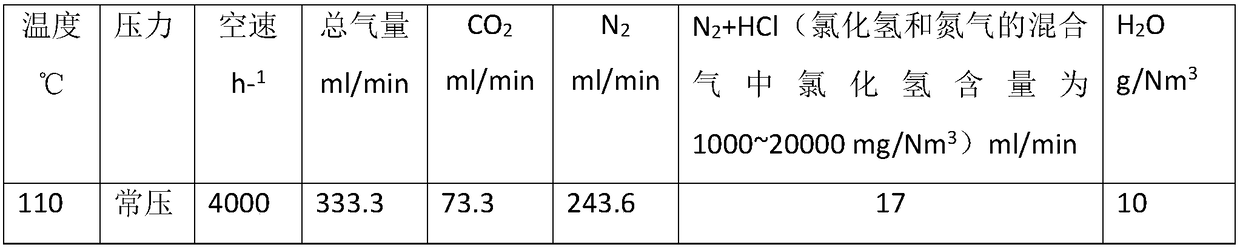

[0057] The evaluation test method of dechlorination agent is as follows:

[0058] Because the gas consumption of the original particle size test is too large, it is impossible to detect the strength of the dechlorination agent after use. The lower end of the reactor that first contacts the gas source is filled with 20 grains of the original particle dechlorination agent with a length of about 5 mm (the finished product of the dechlorination agent prepared by the above method) ), and 5ml of 20-40 mesh ...

Embodiment 2

[0068] Add light calcium carbonate and attapulgite binder into the kneader respectively, the mass fraction of calcium carbonate in the dechlorination agent is 50%, then add a certain amount of water, fully knead, the amount of water added depends on the water absorption of the raw materials, and then Extruded into a clover shape, kept in a natural environment overnight, dried at 120°C for 5 hours, and made into a finished dechlorination agent with a strength of 261N / cm.

[0069] The evaluation test method of dechlorination agent is as follows:

[0070] Because the gas consumption of the original particle size test is too large, it is impossible to detect the strength of the dechlorination agent after use. Fill 20 grains of the original particle dechlorination agent with a length of about 5mm in the lower end of the reactor first contacting the gas source, and fill the top with 20-40 mesh granulation 5ml of dechlorination agent, which not only saves gas volume, but also obtains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com