Normal temperature dechlorination agent and preparation method thereof

A dechlorination agent and normal temperature technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problem that the purification degree can only reach less than 1PPm, and achieve superior performance and adsorption capacity Enhanced, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 6mmol of Zn(NO 3 ) 2 ·6H 2 O and 6 mmol of imidazolium chloride 1,3 diacetate were placed in a 200 mL Erlenmeyer flask, and 100 mL of DMF was added, stirred and dissolved to obtain a clear solution.

[0037] Put 50g of carbon black into the solution and stir well, put them together in a stainless steel reaction kettle, then add 20ml of DMF, crystallize at 200°C for 5 days, wash the crystals with DMF and 1,2 dichloromethane for several times , and then vacuum-dried at 80°C for 6 hours to obtain the dechlorinating agent precursor;

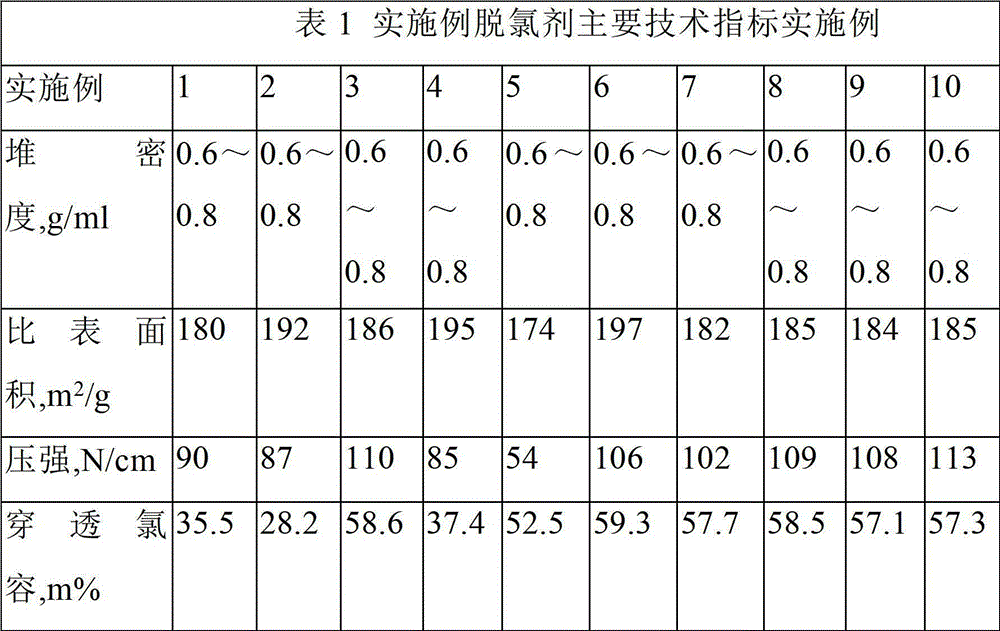

[0038] The obtained activated carbon-containing dechlorination agent precursor and the slurry calcium hydroxide are uniformly mixed in a weight ratio of 2:8, and then pressed into tablets or extruded, dried (20wt% CO should be introduced into the air) 2 gas) to get the dechlorination agent of the present invention. The physical properties and chlorine capacity of the dechlorination agent are shown in Table 1.

Embodiment 2

[0040] The metal ligand in embodiment 2 is changed into 6mmol of Al(NO 3 ) 3 9H 2 O, other steps are the same. The physical properties and chlorine capacity of the dechlorination agent are shown in Table 1.

Embodiment 3

[0042] The metal ligand in embodiment 1 is changed into 6mmol of Ca(NO 3 ) 2 4H 2 O, other steps are the same. The physical properties and chlorine capacity of the dechlorination agent are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com