C9 petroleum resin prehydrogenation catalyst and preparation method and application

A petroleum resin and catalyst technology, which is applied in the field of C9 petroleum resin prehydrogenation catalyst, can solve the problems of clean removal, no mention of chlorine removal ability, no mention of sulfur, etc., and achieve high dispersion, high chlorine capacity and Sulfur capacity, the effect of improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

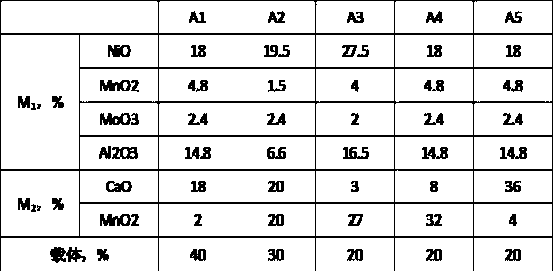

Method used

Image

Examples

Embodiment 1

[0024]Add 175g of nickel nitrate, 33.8g of manganese acetate and 124g of aluminum sulfate into water to prepare solution I, and co-precipitate solution I and 0.5mol / L sodium hydroxide solution, control the reaction temperature at 60°C, and the pH of the system at 10. After completion, continue to stir at constant temperature for 3 hours to obtain a layered precipitate of nickel, manganese, and aluminum ternary hydrotalcite. The precipitate is filtered and washed, and then the above precipitate is added to water to prepare a slurry. Dissolve 7.4g of ammonium heptamolybdate in water, add 2g of sodium dodecylsulfonate to prepare solution II, stir and heat to 65°C, then add the ternary layered structure precipitated slurry obtained above into solution II, Reflux reaction at 100°C for 5h, filter the obtained precipitate, wash and dry to obtain component M 1 precursors.

[0025] Add 132g of calcium nitrate and 14.1g of manganese acetate into water to prepare solution III, stir and ...

Embodiment 2

[0028] Add 216g of nickel acetate, 10.3g of manganese nitrate and 162g of aluminum nitrate into water to prepare solution I, and co-precipitate solution I and 0.5mol / L ammonia solution in parallel, control the reaction temperature to 90°C, and the pH of the system to be 8. After the precipitation is completed Continue stirring at constant temperature for 5 hours to obtain a layered precipitate of nickel, manganese, and aluminum ternary hydrotalcite, filter and wash the precipitate, and then add the above precipitate into water to prepare a slurry. Dissolve 9.2g of ammonium tetramolybdate in water, and add 3g of dodecyltrimethylammonium bromide to prepare solution II, stir and heat to 50°C, and then add the ternary layered structure precipitated slurry obtained above into the solution In II, reflux at 120°C for 3 hours, filter the obtained precipitate, wash and dry to obtain component M 1 precursors.

[0029] Add 188g of calcium acetate and 137g of manganese nitrate into water...

Embodiment 3

[0032] Add 213g of nickel nitrate, 22.5g of manganese acetate and 243g of aluminum nitrate into water to prepare solution I, and co-precipitate solution I and 0.5mol / L sodium hydroxide solution in parallel, control the reaction temperature to 75°C, and the pH of the system to be 11. After completion, continue to stir at constant temperature for 4 hours to obtain a layered precipitate of nickel, manganese, and aluminum ternary hydrotalcite, filter and wash the precipitate, and then add the above precipitate to water to prepare a slurry. Dissolve 4.9g of ammonium heptamolybdate in water, and add 3g of cetyltrimethylammonium bromide to prepare solution II, stir and heat to 80°C, then add the ternary layered structure precipitated slurry obtained above into the solution In II, reflux at 80°C for 4 hours, filter the obtained precipitate, wash and dry to obtain component M 1 precursors.

[0033] Add 16.9g of calcium acetate and 111g of manganese nitrate into water to prepare soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com