Screw air elutriation fine-coal remover for dry classification before fine coal preparation

A technology of spiral wind and fine-grained coal, which is applied in the direction of separating solids from solids with airflow, filtering and sieving, and solid separation, can solve problems such as inability to guarantee classification efficiency, waste of resources and environment, and poor adaptability of coal types. Solve the problem of sieve clogging, improve the sorting efficiency, and avoid the effect of conveying dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

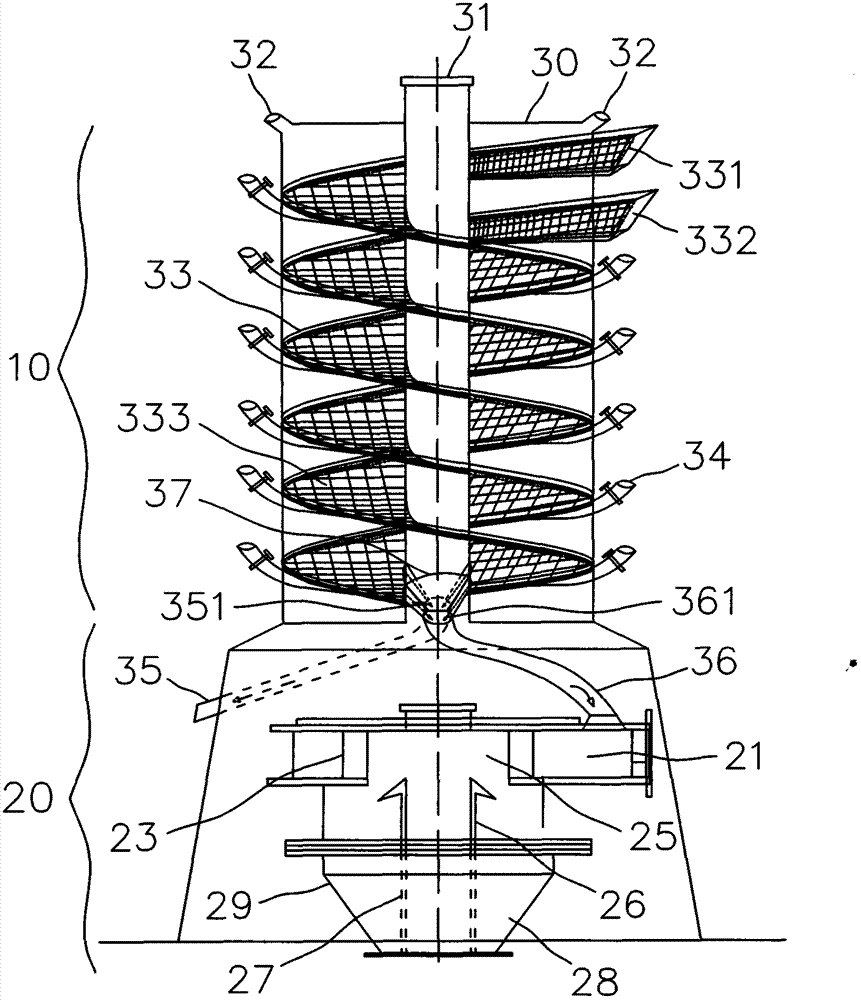

[0049] Such as figure 1 , 2 As shown, a spiral air screen dedusting machine used for dry classification before fine-grained coal selection includes the following components:

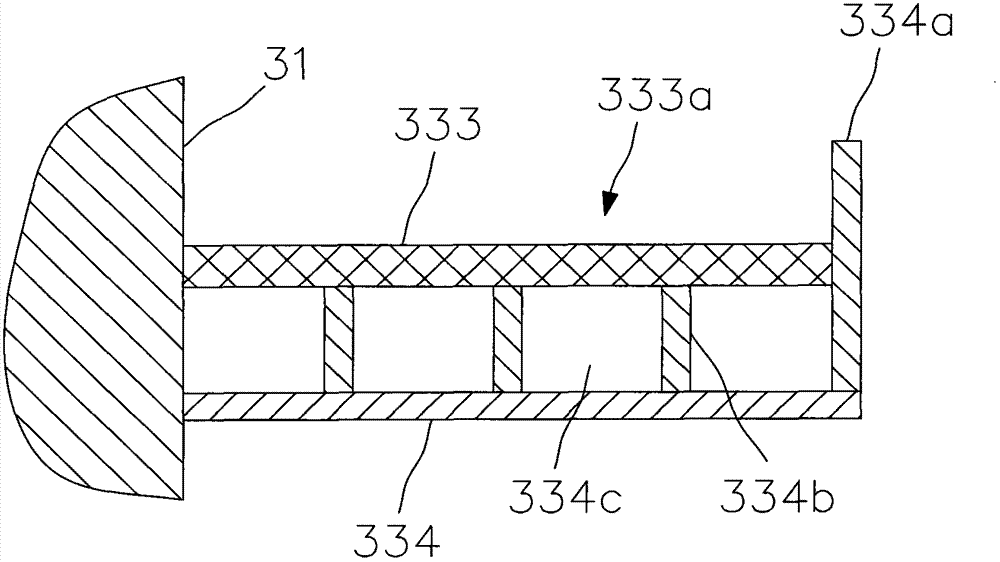

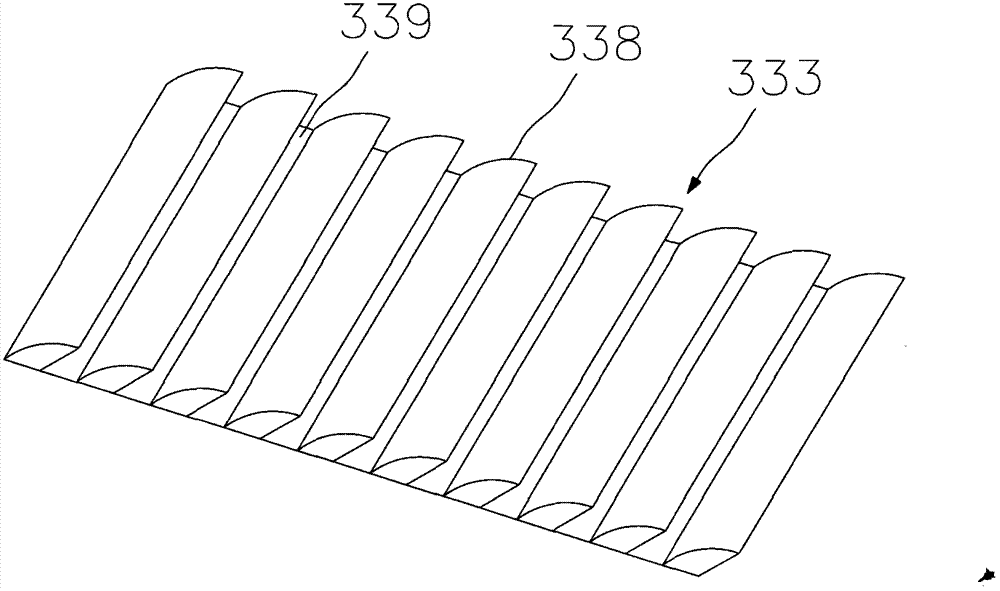

[0050] The primary classification area 10, the primary classification area 10 includes a cylindrical first classification bin 30, the first classification bin 30 is provided with a central column 31, and the upper side of the first classification bin 30 is provided with a dust removal port 32; the central column 31 is at least provided with a spiral sorting screen 33, the upper side of the spiral sorting screen 33 is provided with a feed port 331, and the lower side of the spiral sorting screen 33 is at least provided with a first coarse material discharge pipe 35 and a second A fine material discharge pipe 36, between the upward coarse material discharge port 351 of the opening of the first coarse material discharge pipe 35 and the upward fine material discharge port 361 of the first fine material disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com