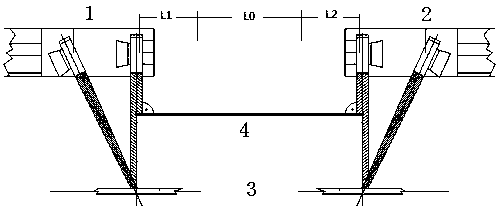

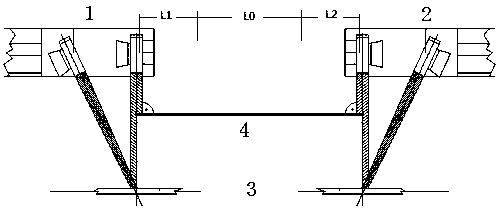

Method for online calibration of width gauge

A calibration method and technology of width measuring instrument, which are applied to instruments, measuring devices, and electrical devices, etc., can solve the problems of easy damage of high-precision instruments, difficulty in calibration work, difficult disassembly and installation of equipment, etc., so as to achieve easy implementation and calibration. The effect of scientific method, time saving and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

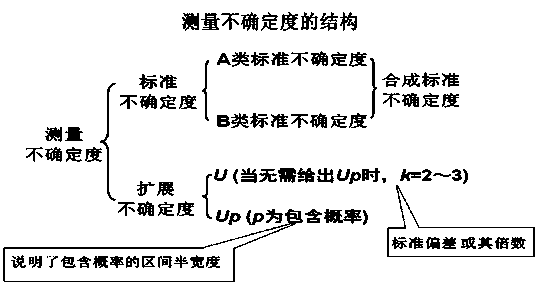

[0071] The invention includes a calibration method and a matching template. The calibration method is a set of operating steps under specified conditions. One is to determine the relationship between the value provided by the measurement standard and the corresponding indication value, and the other is to use this information to determine the relationship between the measurement results obtained from the indication value. Here Quantities and corresponding indications provided by measurement standards have measurement uncertainties. The conditions that must be met to carry out the calibration of the width gauge according to the definition of the above calibration method are: a measurement standard (sample) that can provide a reference standard value; a calibration that can establish the relationship between the value provided by the measurement standard and the corresponding indication value (width gauge) Methods; data processing methods; evaluation of measurement uncertainty o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com