Drive device with electric furl

A technology of driving device and electric coil, which is applied in the direction of electromechanical device, transmission device, gear transmission device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

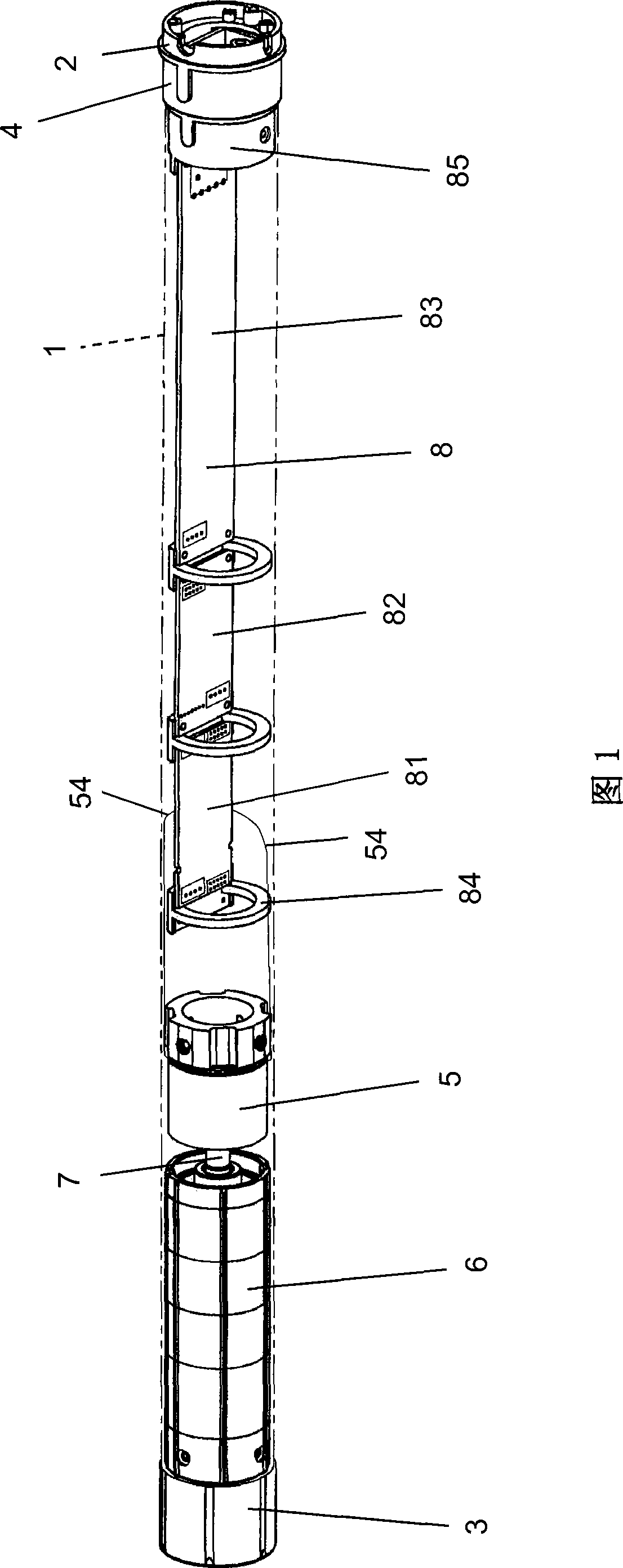

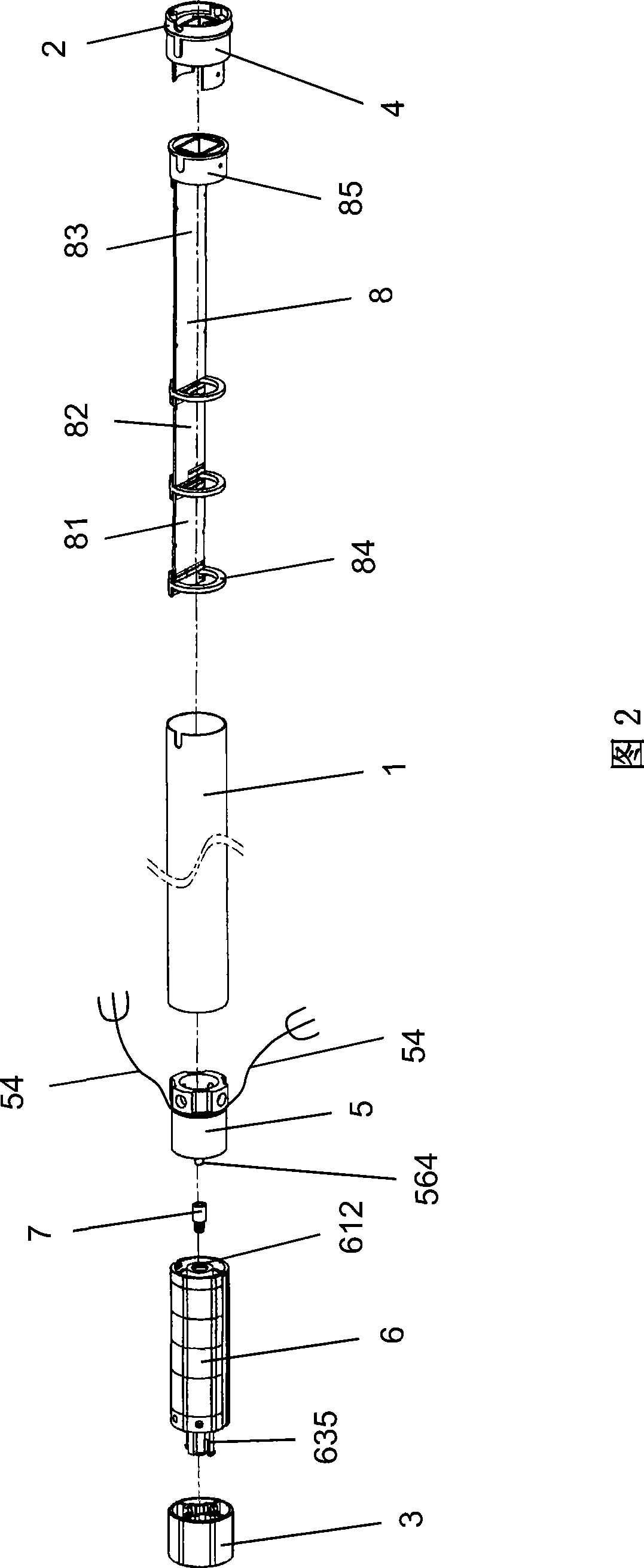

[0079] Such as figure 1 and figure 2 As shown, the present invention provides a driving device with electric retraction, which includes a housing 1, a motor tube end cover 2, a transmission wheel 3, a crown ring 4, a permanent magnet DC brushless motor 5, a speed reducer Machine 6, a power transmission assembly 7 and a driving machine 8, the housing 1 is a hollow tubular body with two ends open, the permanent magnet brushless DC motor 5, the reducer 6, the power transmission assembly 7 and the drive The motors 8 are all located in the housing 1, and the crown ring 4 is sleeved on the outer peripheral wall of the motor tube end cover 2. The motor pipe end cover 2 is connected with the driving machine 8 , and the transmission wheel 3 is connected with the casing 1 and the reducer 6 .

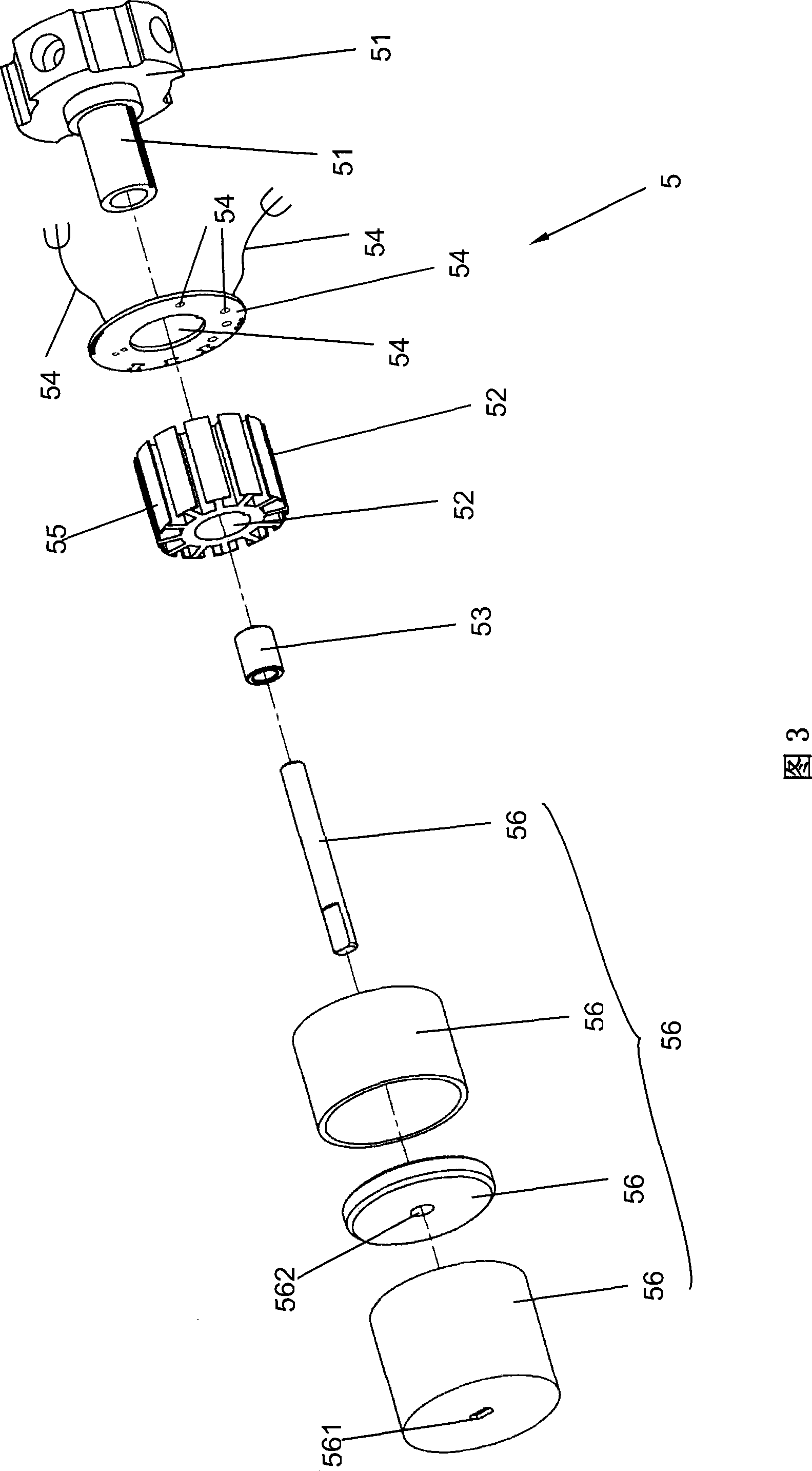

[0080] Such as image 3As shown, the permanent magnet brushless DC motor 5 includes a base 51, a stator 52, a bearing 53, a circuit board 54, a plurality of induction coils 55 and a rotor 56,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com