On-line repair method for roller surface of roller press

A repair method and roller press technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as the failure of the service life of the roller surface, the loss of the manufacturer, and the loss of the user, so as to achieve low repair costs, Good extrusion effect and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

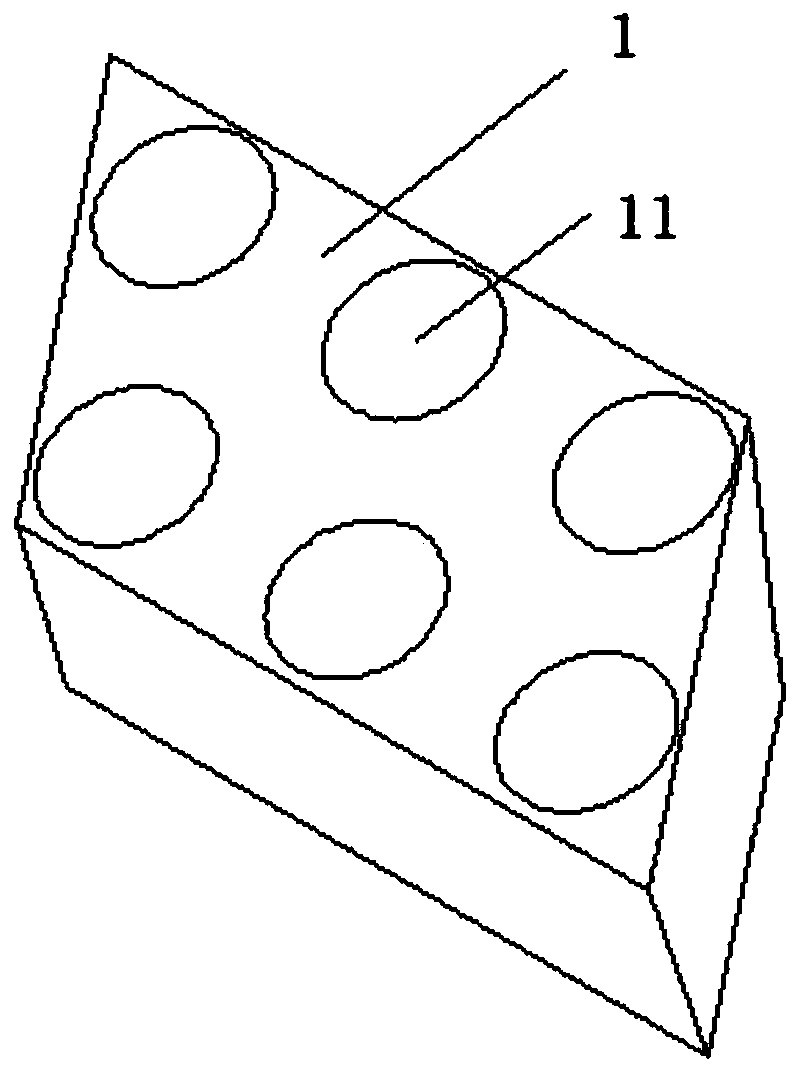

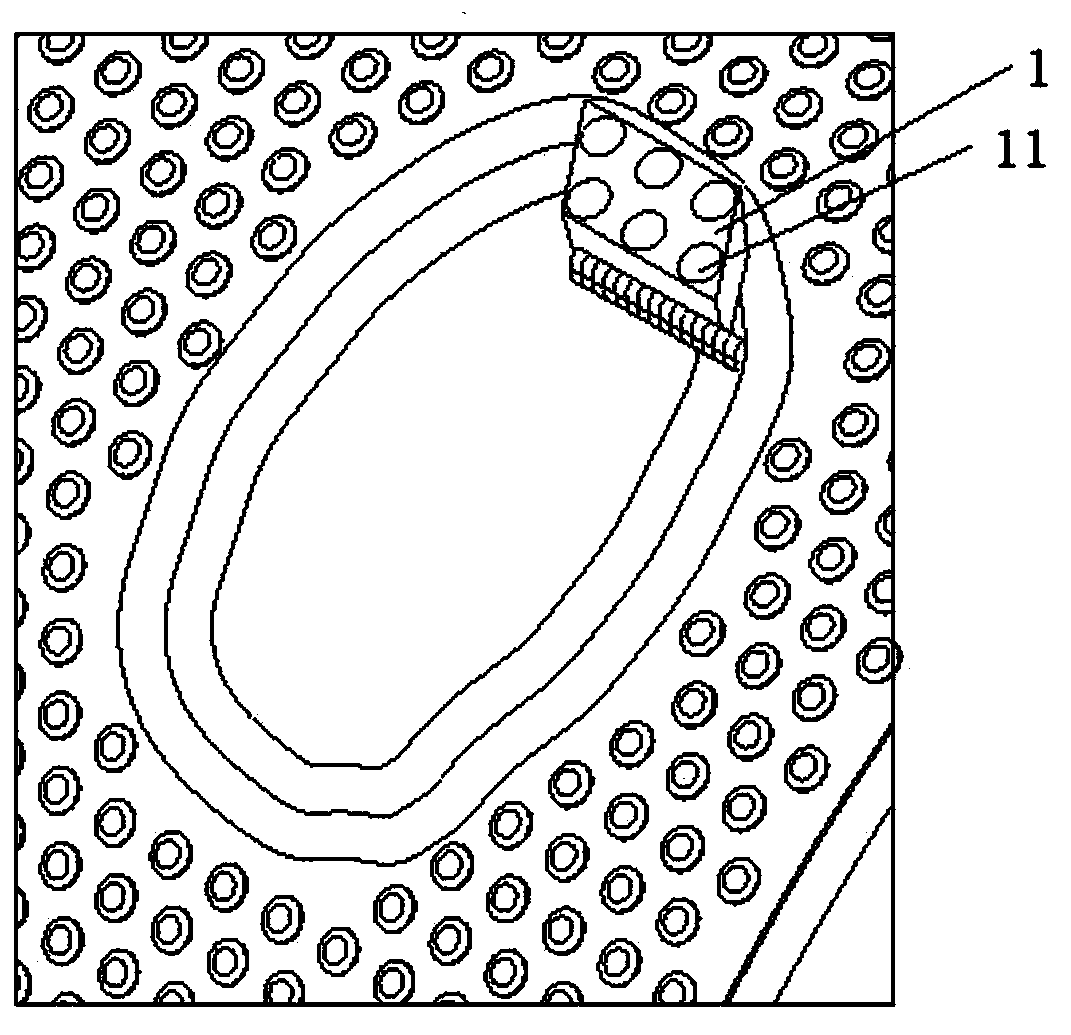

[0036] Such as figure 1 , 3 And 6 a kind of online repair method of roll surface of roller press, comprises the following steps:

[0037] S1: Make several prefabricated wear-resistant blocks 1;

[0038] S2: Weld the prefabricated wear-resistant block 1 to the damaged area 3 of the roller surface in turn to form several installation welds;

[0039] S3: welding adjacent prefabricated wear-resistant blocks 1 to form a connecting weld 5;

[0040] S4: welding the prefabricated wear block 1 to the normal roll surface to form a transition surface;

[0041] S5: A transitional wear-resistant structure is provided on the transition surface along the direction in which the wear-resistant structure 2 extends outward;

[0042] S6: Assemble a stud in the stud hole 11 .

[0043] The length, width and height of the prefabricated wear-resistant block are respectively 40-80mm, 80-120mm and 20-80mm.

[0044] The material mass components of the prefabricated wear-resistant block are: C 0.9-...

Embodiment 2

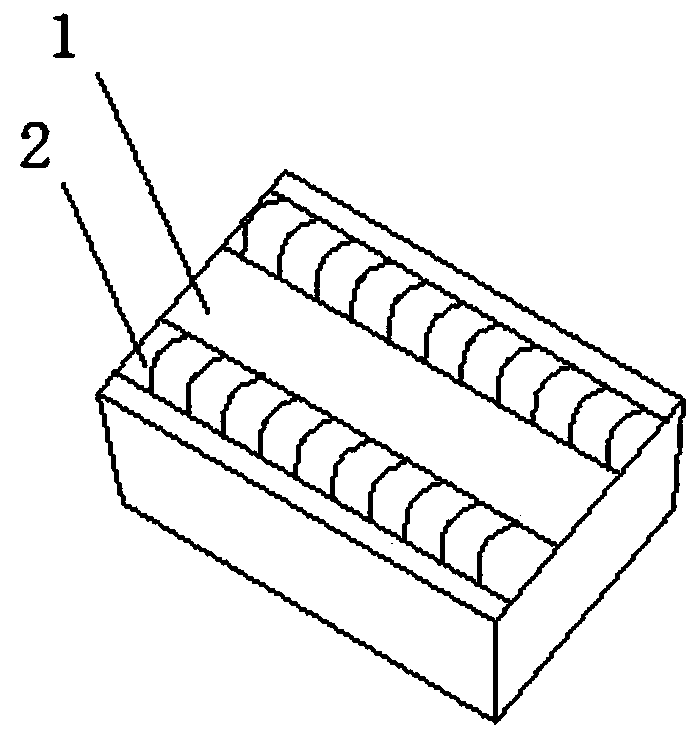

[0051] Such as figure 2 , 5 and 8 are a kind of online repair method for the roll surface of a roller press according to the present invention

[0052] An online repair method for the roller surface of a roller press, comprising the following steps:

[0053] S1: Make several prefabricated wear-resistant blocks 1;

[0054] S2: Weld the prefabricated wear-resistant block 1 to the damaged area 3 of the roller surface in turn to form several installation welds;

[0055] S3: setting a wear-resistant structure 2 on the surface of the prefabricated wear-resistant block 1;

[0056] S4: welding adjacent prefabricated wear-resistant blocks 1 to form a connecting weld 5;

[0057] S5: welding the prefabricated wear block 1 to the normal roll surface to form a transition surface;

[0058] S6: A transitional wear-resistant structure is provided on the transition surface along the direction in which the wear-resistant structure 2 extends outward.

[0059] The dimensions of the length,...

Embodiment 3

[0066] Such as Figure 4 and 8 It is an online repair method for the roller surface of a roller press according to the present invention

[0067] An online repair method for the roller surface of a roller press, comprising the following steps:

[0068] S1: Make several prefabricated wear-resistant blocks 1;

[0069] S2: Weld the prefabricated wear-resistant block 1 to the damaged area 3 of the roller surface in turn to form several installation welds;

[0070] S3: welding adjacent prefabricated wear-resistant blocks 1 to form a connecting weld 5;

[0071] S4: welding the prefabricated wear block 1 to the normal roll surface to form a transition surface;

[0072] S5: A wear-resistant structure 2 is provided on the wear-resistant block 1, and a transitional wear-resistant structure is provided on the transition surface along the direction in which the wear-resistant structure 2 extends outward.

[0073] The dimensions of the length, width and height of the prefabricated wea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com