Integral type foundation structure for assembling wind driven generator and preparation method of integral type foundation structure

A technology for wind turbines and infrastructure, applied in infrastructure engineering, installation/support of wind turbine configuration, wind power generation, etc., can solve problems such as difficulty in concrete pouring, cracks at nodes, corrosion, etc. Easy installation and guaranteed durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

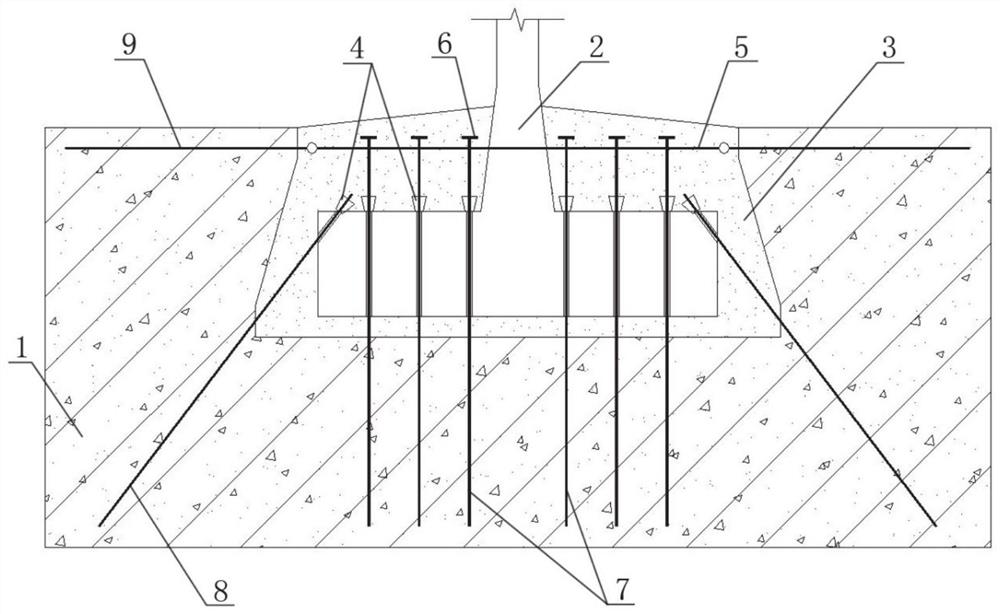

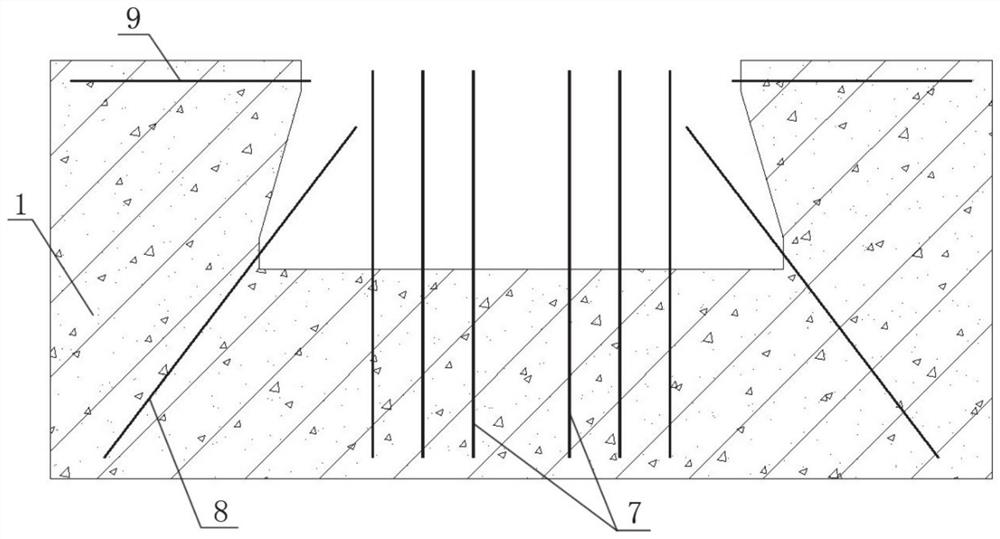

[0045] Such as figure 1 , figure 2 with image 3 As shown, Embodiment 1 of the present disclosure provides a wind turbine assembly integrated foundation structure, including: prefabricated concrete foundation 1, wind turbine finished steel foundation 2, secondary grouting 3 (that is, the slurry in the groove), anchorage 4. Horizontal bars 5 and anchor bars 6 in the grouting layer.

[0046] The central area of the top surface of the precast concrete foundation 1 reserves a groove for later installation and grouting. The groove adopts the structural form of the bottom reaming. In this embodiment, the groove is from top to bottom along the vertical axis of the groove. The shape of the horizontal cross-section is the same and the horizontal cross-sectional area gradually increases.

[0047] It can be understood that, in some other embodiments, the horizontal cross-sectional area of the groove increases gradually from top to bottom along the vertical central axis of the gro...

Embodiment 2

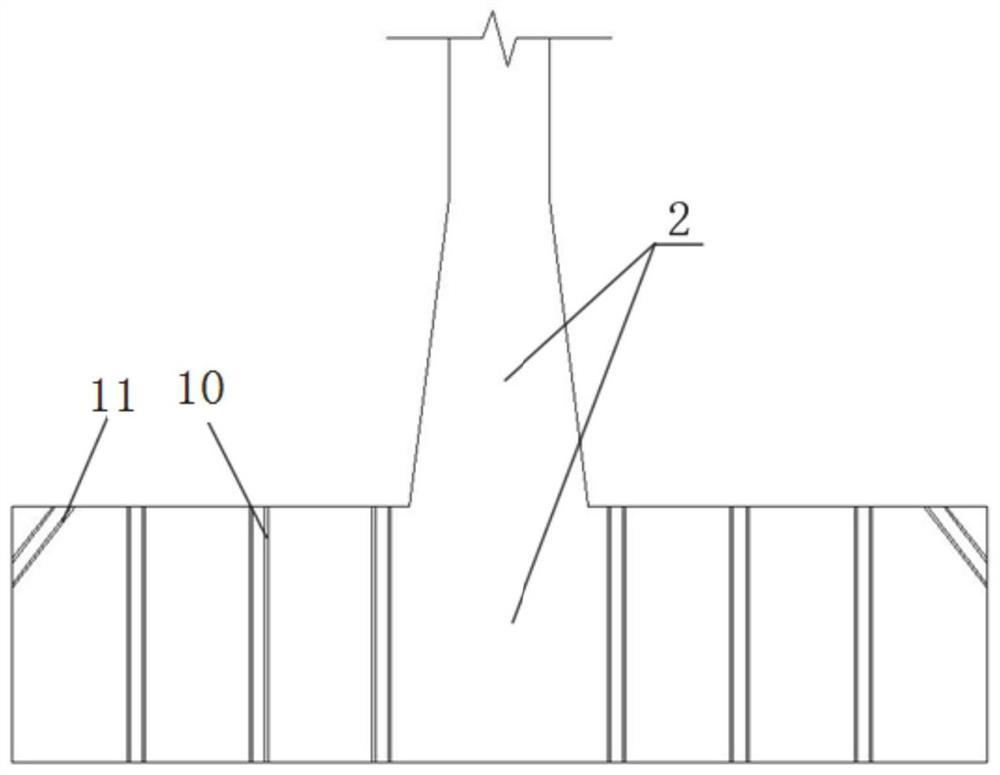

[0055] Such as Figure 4 As shown, embodiment 2 of the present disclosure provides a method for preparing a wind turbine assembly monolithic infrastructure, including the following process:

[0056] One end of the vertical prestressed tendon is poured at the same time as the precast concrete foundation, and the remaining part of the vertical prestressed tendon passes through the vertical reinforcement casing to apply prestress on the upper surface of the fan steel foundation, and through the fixing piece on the surface of the fan steel foundation Fixing, the remaining part of the vertical prestressing tendon extends upwards to the upper part of the slurry in the groove and welds with the anchoring tendon;

[0057] One end of the oblique prestressed tendon is poured at the same time as the precast concrete foundation, and the remaining part of the oblique prestressed tendon passes through the oblique reinforcement casing obliquely to apply prestress on the surface of the fan st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com