Uncertainty Analysis Method for Determination of Carbon Dioxide Concentration in Industrial Flue Gas Based on Infrared Spectroscopy

A technology of industrial flue gas and carbon dioxide, which is applied in the direction of material analysis, material analysis, and measuring devices through optical means, and can solve the problems of poor online applicability, high cost, and short response time in large batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

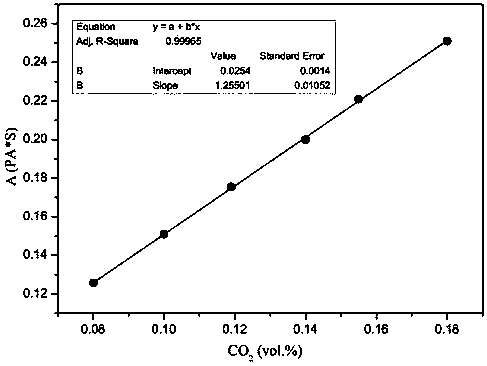

[0071] An uncertainty analysis method for measuring carbon dioxide concentration in industrial flue gas based on infrared spectroscopy, comprising the following steps:

[0072] 1) The construction and measurement steps of the carbon dioxide measurement system are as follows:

[0073] ①Construction of carbon dioxide measurement system:

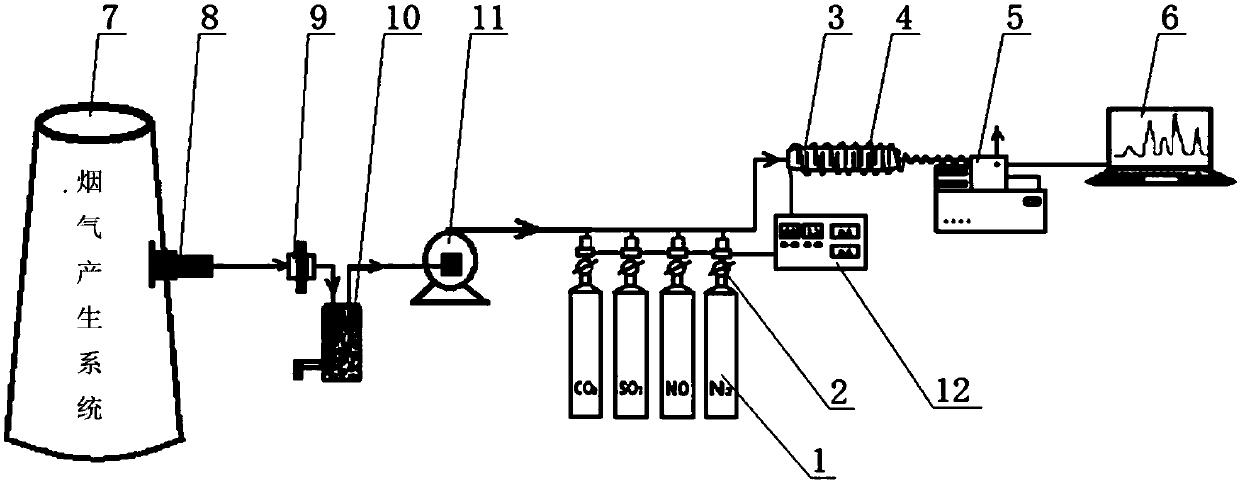

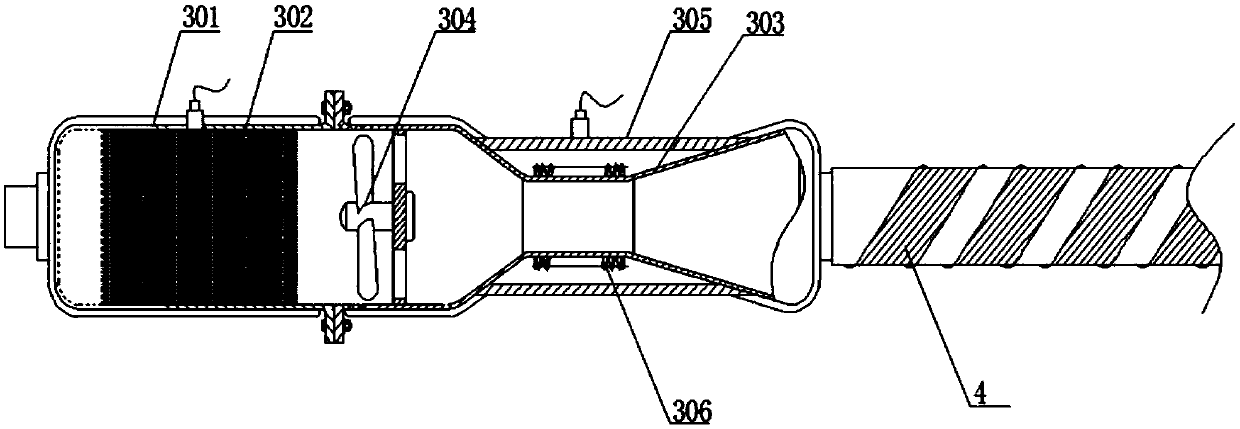

[0074] Carbon dioxide measurement systems such as figure 1 As shown, the system includes a standard gas storage tank 1, a gas mixing heating pool 3 connected to the standard gas storage tank 1 through a vent line, and an IGS gas infrared analyzer 5 connected to the gas mixing heating pool 3 through a gas pipeline , the IGS gas infrared analyzer 5 is electrically connected to the signal input end of the data acquisition device 6; the system also includes a flue gas generation system 7, a sampling gun 8 communicated with the flue gas generation system 7, and a sampling gun 8 connected to the gas sampling system through a ventilation line. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com