Device and method for calibrating flow-dividing vacuum leaking hole

A vacuum leak and split flow technology, applied in the field of measurement, can solve the problem that the calibration result depends on the quadrupole mass spectrometer, etc., and achieve the effects of small measurement uncertainty, avoidance of nonlinear errors, and wide flow measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

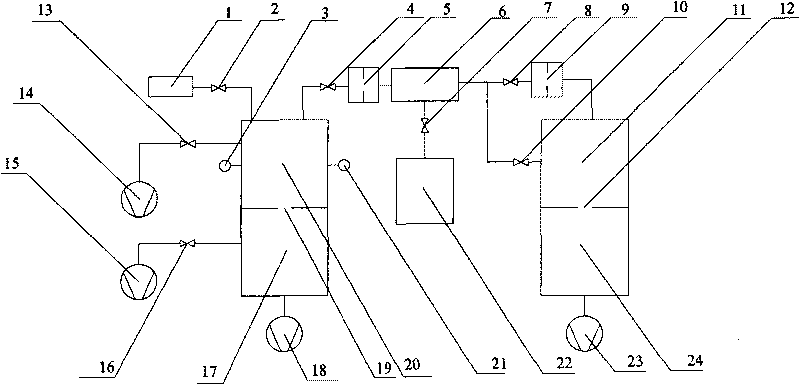

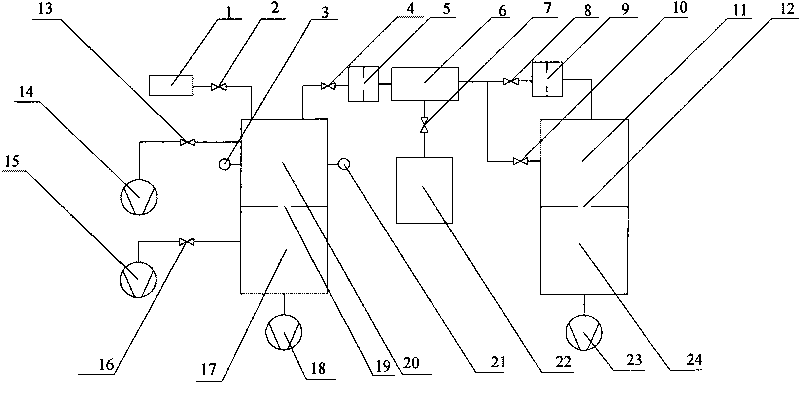

[0023] 1) Open the valve 10, start the oil-free double turbomolecular pump air extraction unit 18 and the ordinary molecular pump air extraction unit 23;

[0024] 2) Baking and degassing the calibration device as a whole. The maximum baking temperature of the ultra-high vacuum calibration chamber 20 and the ultra-high vacuum pumping chamber 17 is 300°C. The ultra-high vacuum pumping chamber 24, ultra-high vacuum calibration chamber 11 and shunt The maximum baking temperature of chamber 6 is 200°C, and the maximum baking temperature of flowmeter 22 is 150°C. From room temperature, the temperature is raised at a uniform rate of 30°C / h. Cool down at a uniform rate of / h. When the temperature reaches 100°C, stop baking and let it cool down naturally;

[0025] 3) During the period of maintaining the maximum baking temperature, open the connection valve 13 of the non-evaporable getter pump 14 and the connection valve 16 of the non-evaporable getter pump 15 to activate the non-evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com