Patents

Literature

33results about How to "Avoid nonlinear errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

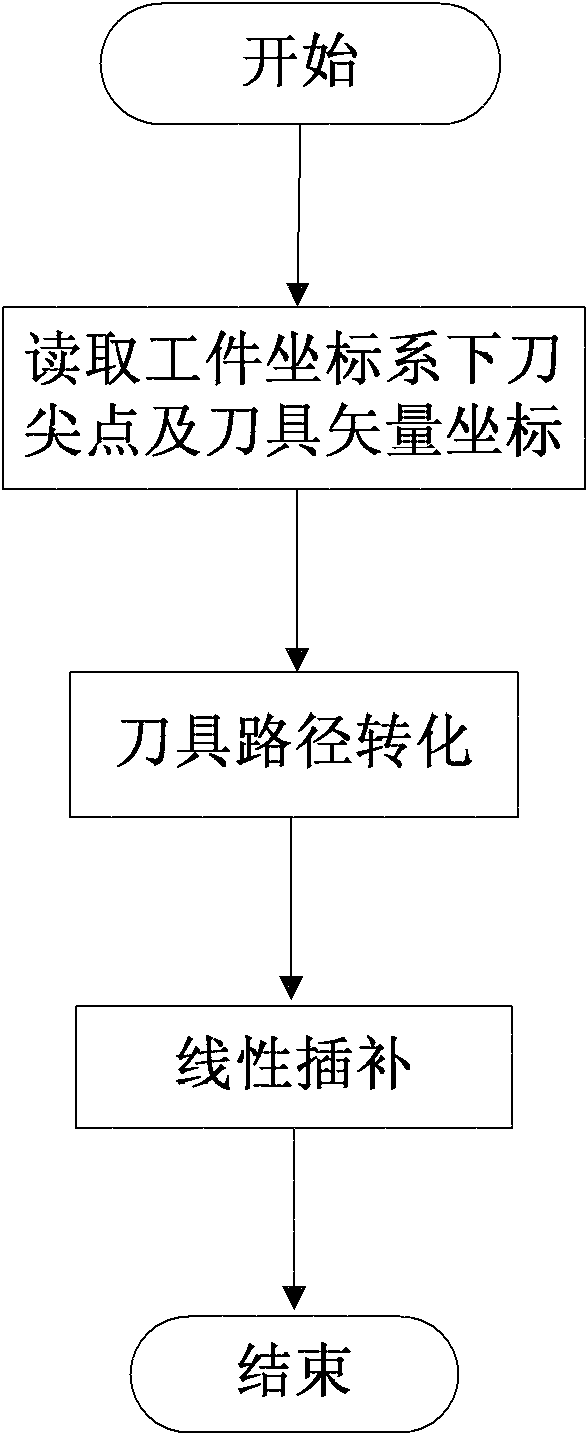

Five-axis numerical control machining method based on interpolation of vector of cutting tool

InactiveCN104635619AFlexible control of vector changesImprove machining accuracyNumerical controlNumerical controlKinematics

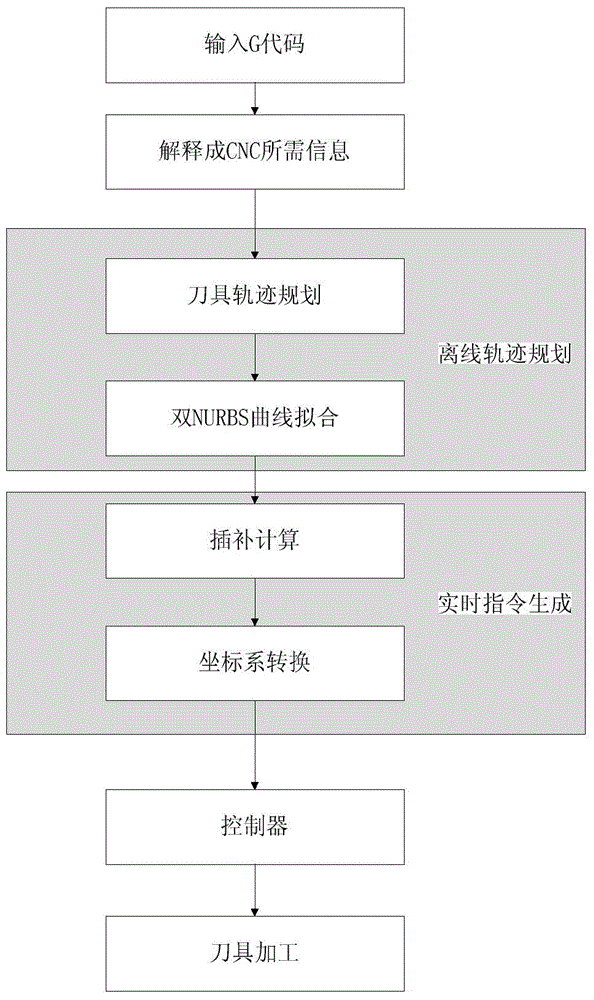

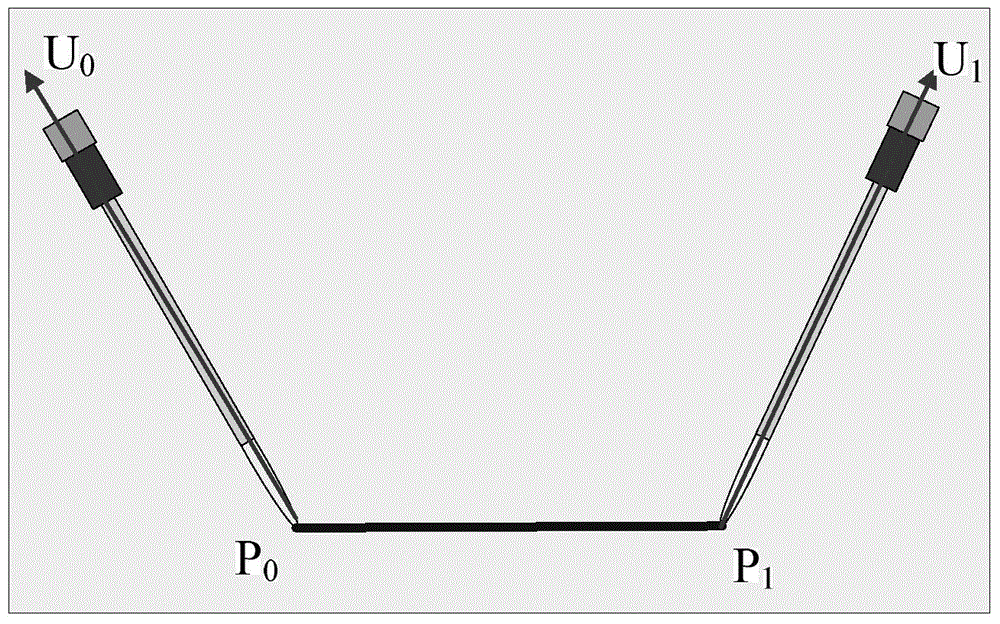

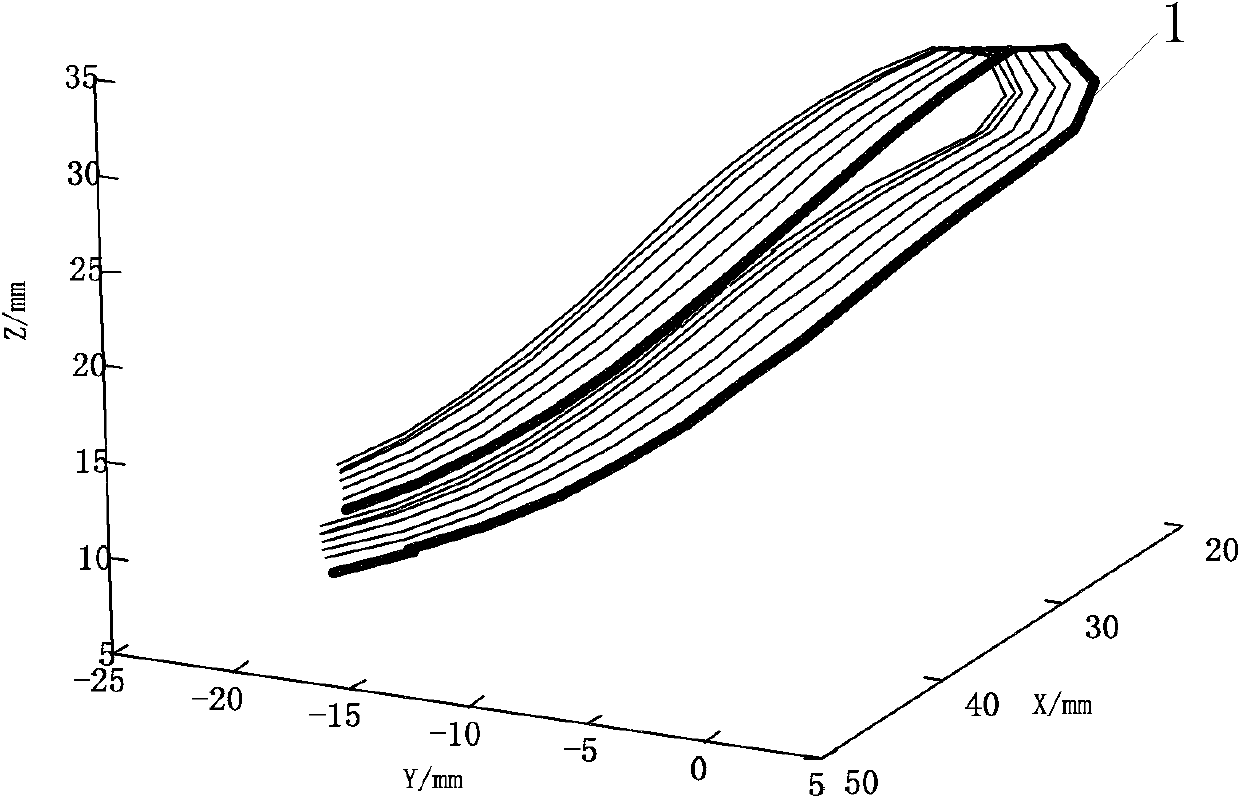

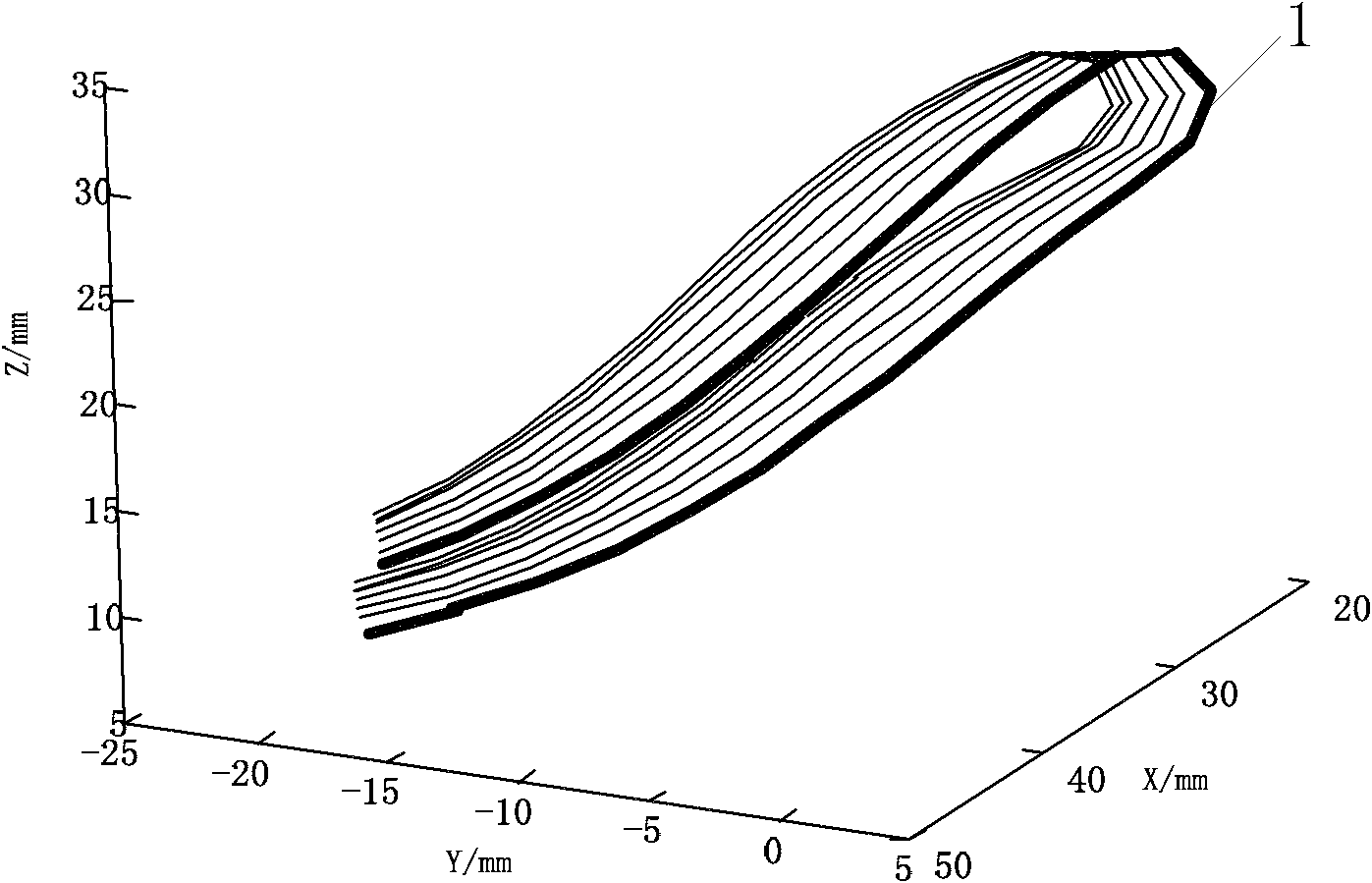

The invention relates to a five-axis linkage numerical control machining technology, in particular to a five-axis numerical control machining method based on interpolation of a vector of a cutting tool. The five-axis numerical control machining method comprises the following steps of cutting tool track planning: performing interpolation calculation on the vector of the cutting tool under a workpiece coordinate system while the point position of the cutting tool is planned so as to obtain a cutting tool track equation after the vector of the cutting tool is subjected to interpolation and a cutting tool nose point value and a cutting tool vector under the workpiece coordinate system; double-NURBS (non-uniform rational B-spline) curve fitting: performing fitting on a curve formed by a cutting tool nose point and a second point on the axis of the cutting tool by using a double-NURBS curve fitting method; interpolation calculation: performing interpolation on a formed NURBS curve according to a feeding speed so as to obtain corresponding various axis coordinate values in a machine tool coordinate system; and machine tool kinematical modeling and solving: establishing a corresponding machine tool kinematical equation for a specific machine tool mechanism and finishing conversion between two coordinate systems. The five-axis numerical control machining method based on interpolation of the vector of the cutting tool has the advantages of high machining precision and high surface machining quality.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

Five-axis numerical control interpolation method based on smooth compression of tool vectors

ActiveCN102566494AGuaranteed Second Order ContinuityAvoid nonlinear errorsNumerical controlComputer science

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

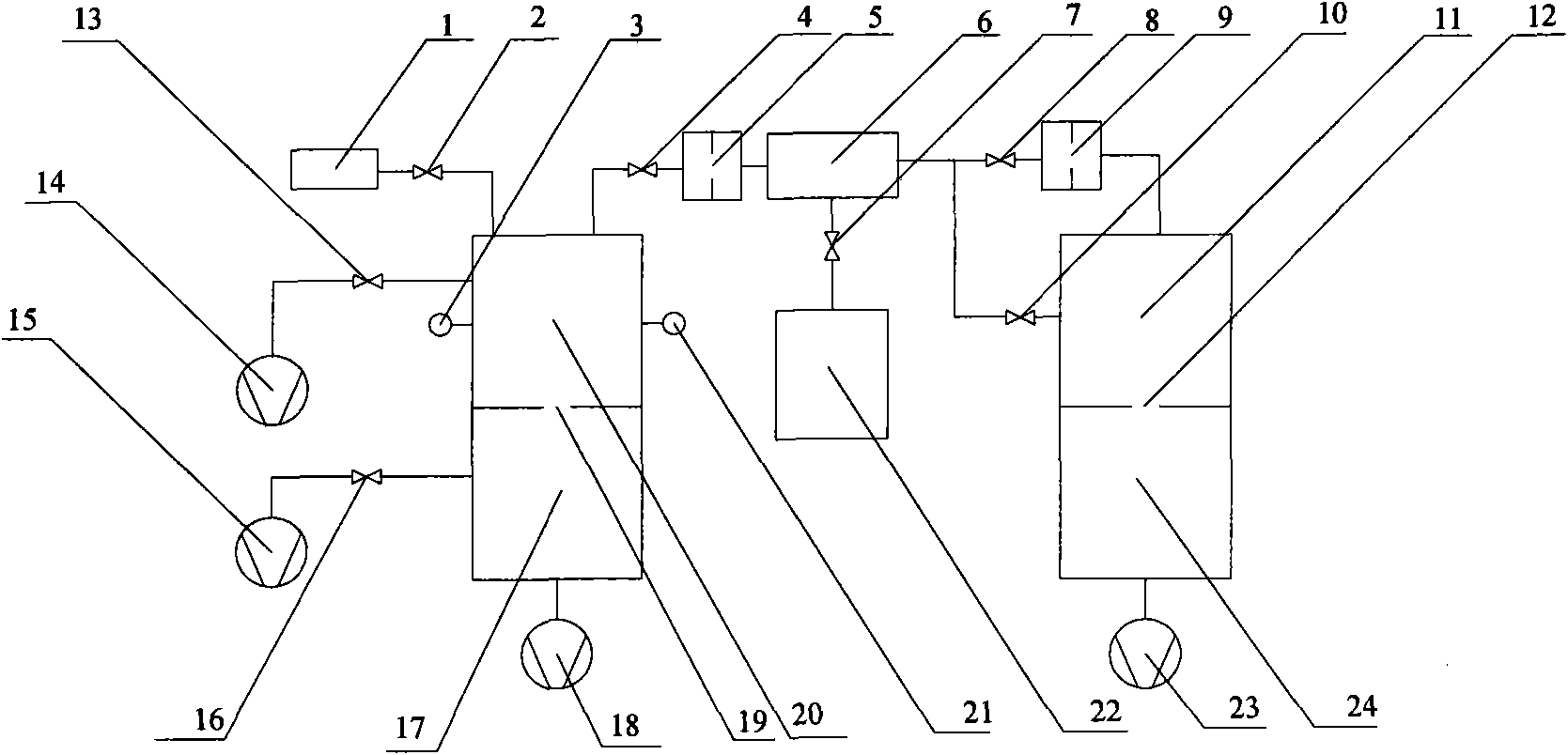

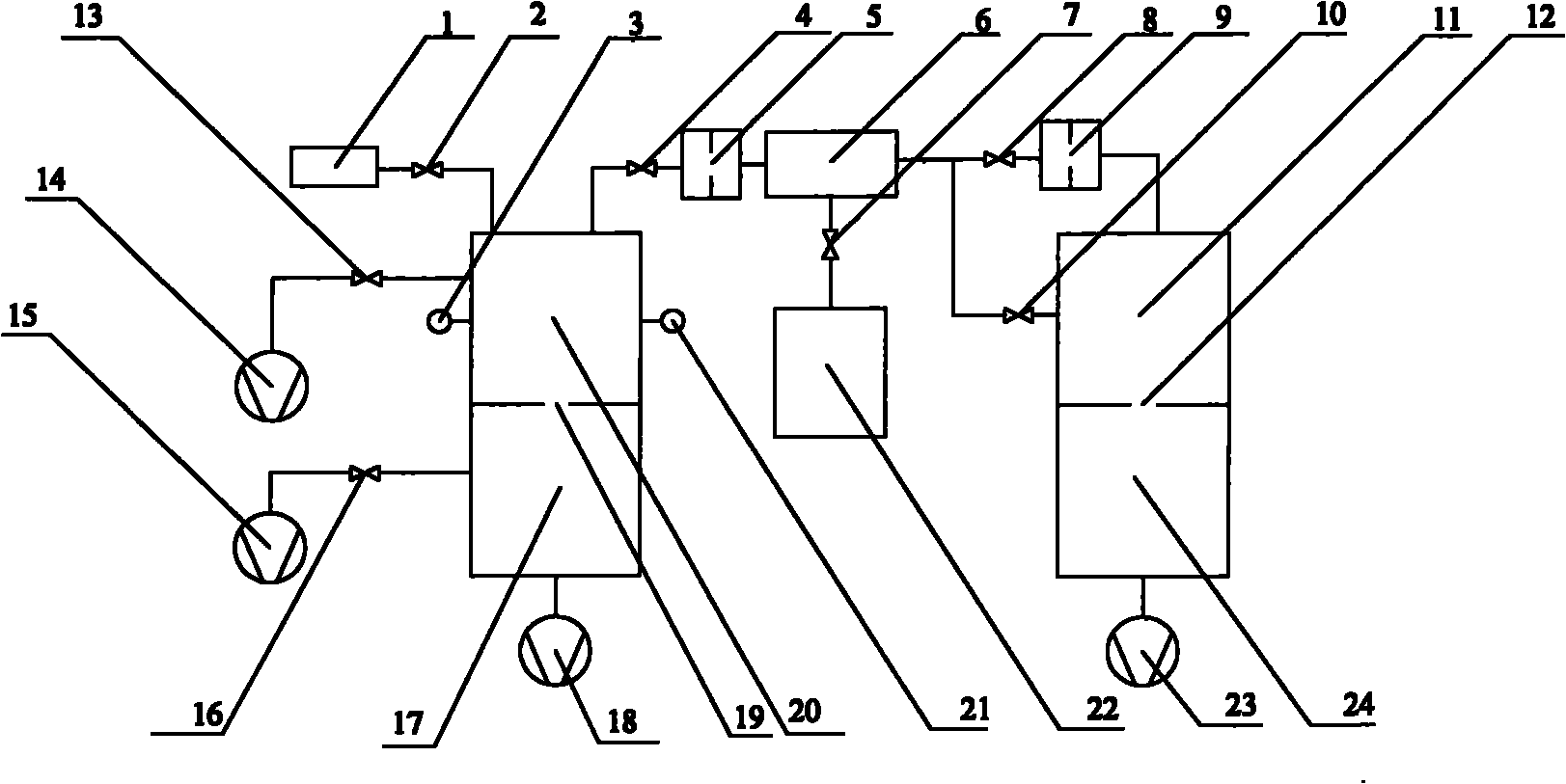

Device and method for calibrating flow-dividing vacuum leaking hole

ActiveCN101713696AWide measurement rangeReduce measurement uncertaintyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateUltra-high vacuumEngineering

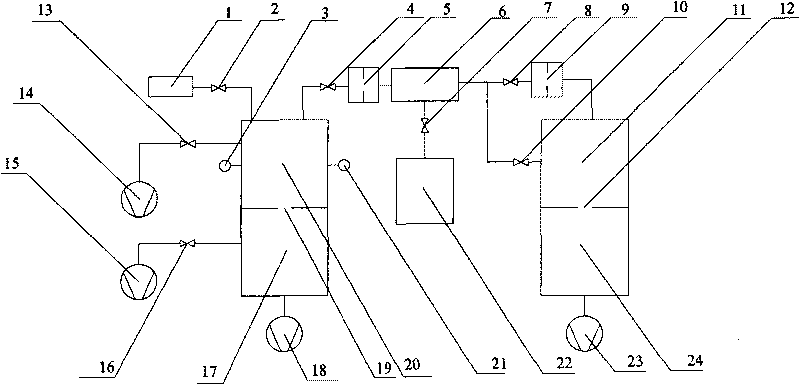

The invention relates to a device and a method for calibrating a flow-dividing vacuum leaking hole, in particular to the device and the method for calibrating the vacuum leaking hole, the leakage value of which is less than 1*10-8 Pa.m3 / s by adopting flow-dividing technology, and belongs to the field of measuring technology. The device consists of the calibrated leaking hole, a valve, an ionization gauge, a small hole, a flow-dividing chamber, a non-evaporable getter pump, an ultrahigh vacuum calibrating chamber, a metering hole, a very high vacuum pumping chamber, an oil-free bi-turbo molecular pump air exhauster set, a quadrupole mass spectrometer, a flow meter, a super-high vacuum calibrating chamber, the metering hole, a super-high vacuum pumping chamber and a common molecular pump air exhauster set. The method adopts a fixed flow method gas micro-flow meter to provide a known gas flow rate, so the measuring range of the flow rate is wide and uncertainty of the measurement is low; and by adopting a flow-dividing method to calibrate the vacuum leaking hole, the method of the invention completely avoids a nonlinear error of the quadrupole mass spectrometer and can precisely calibrate the vacuum leaking hole the leakage value of which is less than 1*10-8 Pa.m3 / s.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

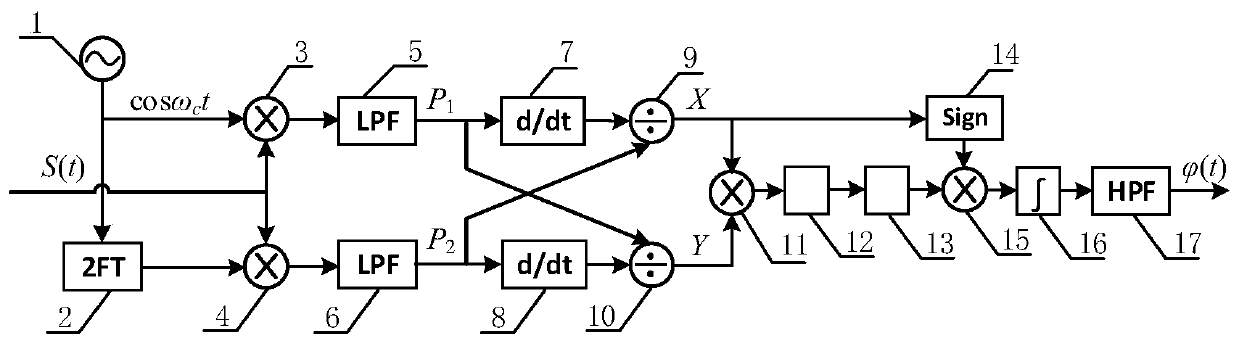

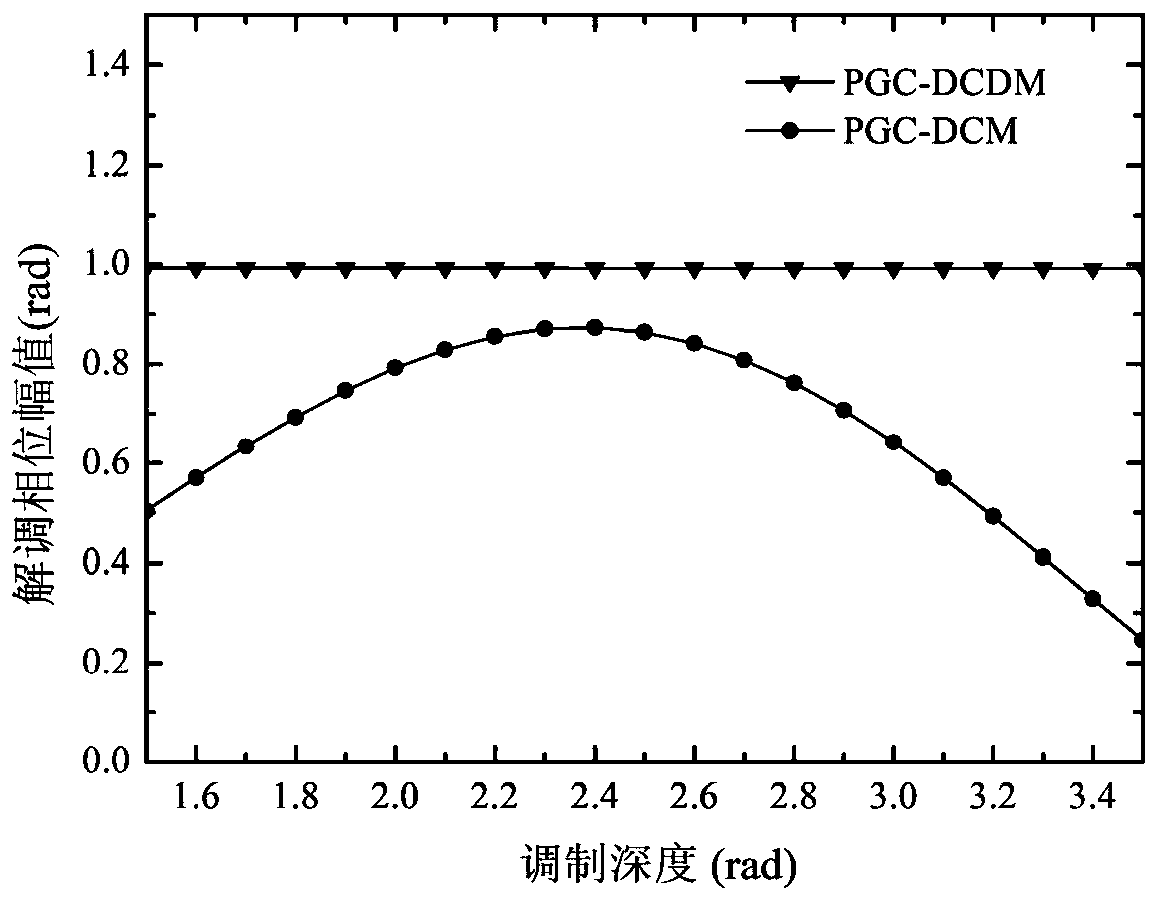

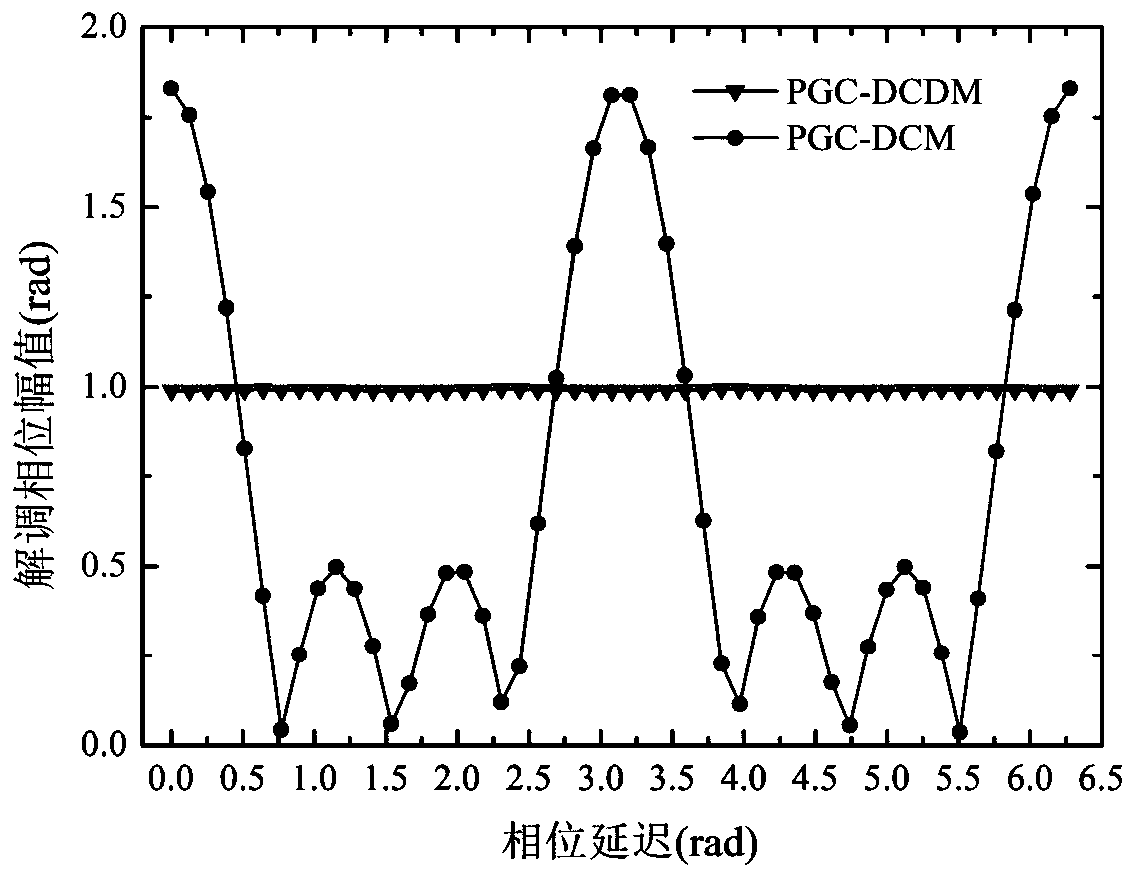

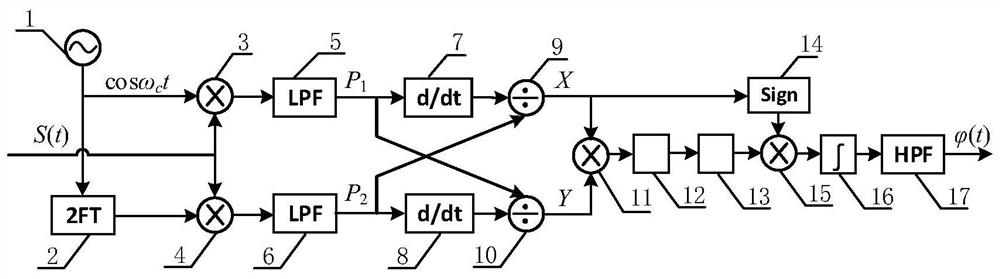

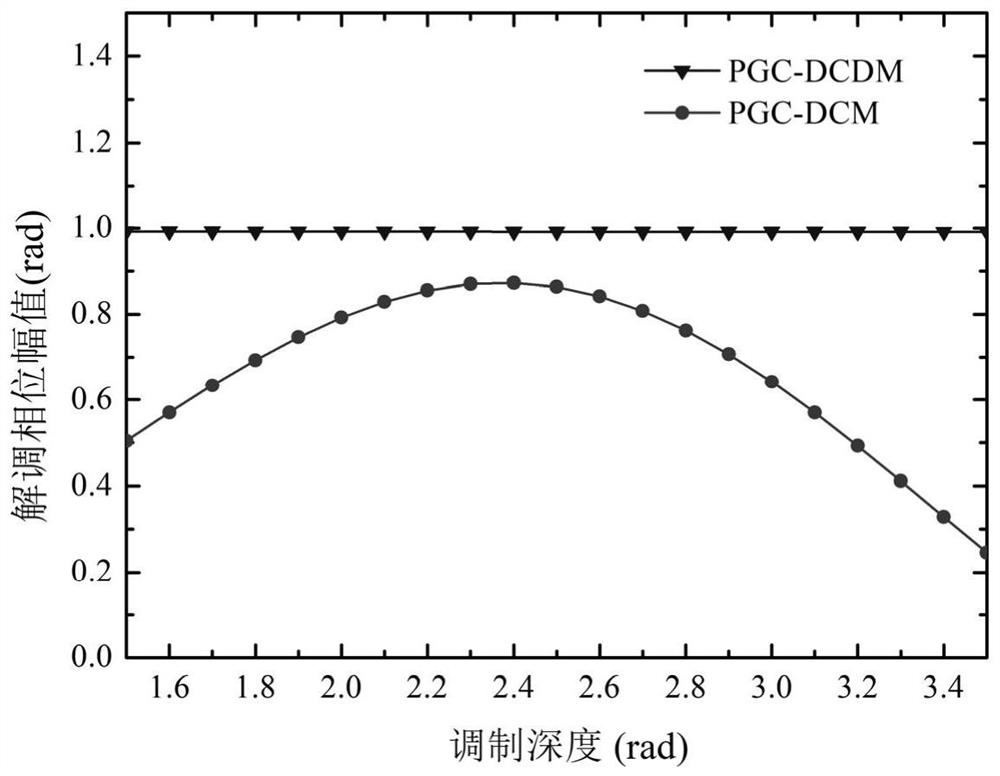

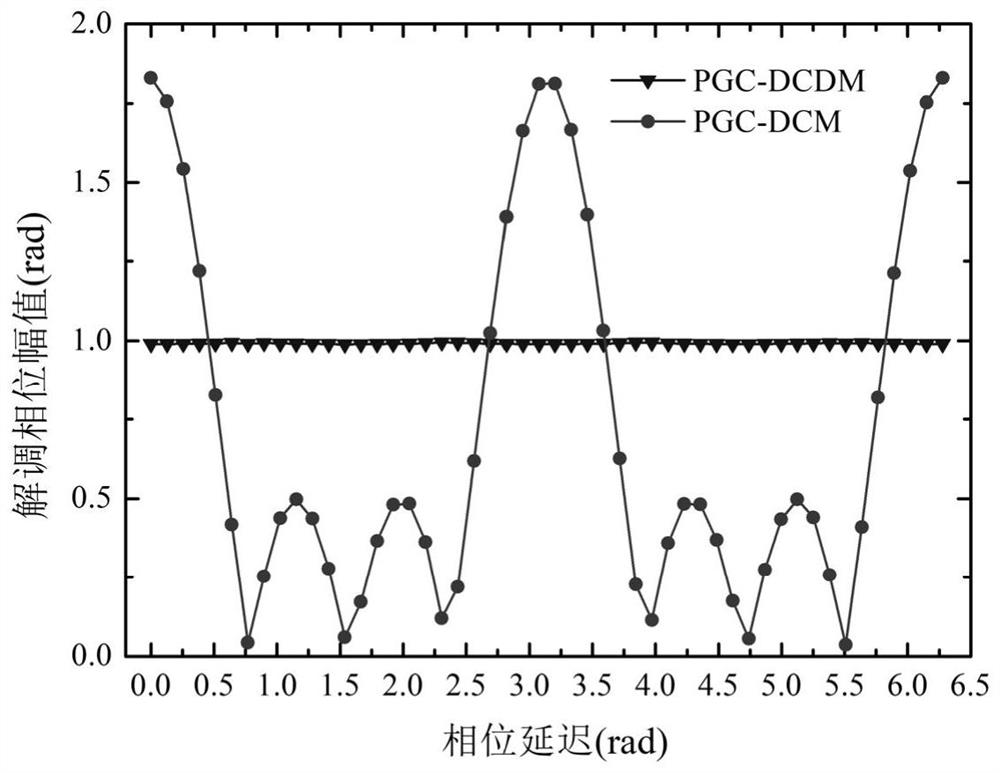

PGC-DCDM demodulation method insensitive to phase delay and modulation depth

ActiveCN110411486ASolve the unmeasurableAvoid nonlinear errorsConverting sensor output opticallyPhase retardationPhase modulation

The invention discloses a PGC-DCDM demodulation method insensitive to phase delay and modulation depth. A sinusoidal phase modulation digital interference signal is separately multiplied by a first-order reference signal and a second-order reference signal and subjected to low-pass filtering to obtain a pair of orthogonal signals related to a to-be-detected phase; the orthogonal signals are subjected to operations of differential cross division and multiplication to obtain an absolute value for extraction of a square root in order to obtain an absolute value of a derivative of the to-be-detected phase; a sign of the derivative of the to-be-detected phase is obtained according to a result obtained after differential cross multiplication and division; the absolute value is combined with thesign to obtain the derivative of the to-be-detected phase; the to-be-detected phase is obtained through an integral operation and a high-pass filtering operation. The method overcomes the influence oferror factors introduced by phase delay and modulation depth in PGC demodulation on a demodulation result, phase demodulation precision is effectively improved, and the method can be widely applied to the fields of interference type optical fiber sensors, sinusoidal phase modulation interferometers and the like.

Owner:ZHEJIANG SCI-TECH UNIV

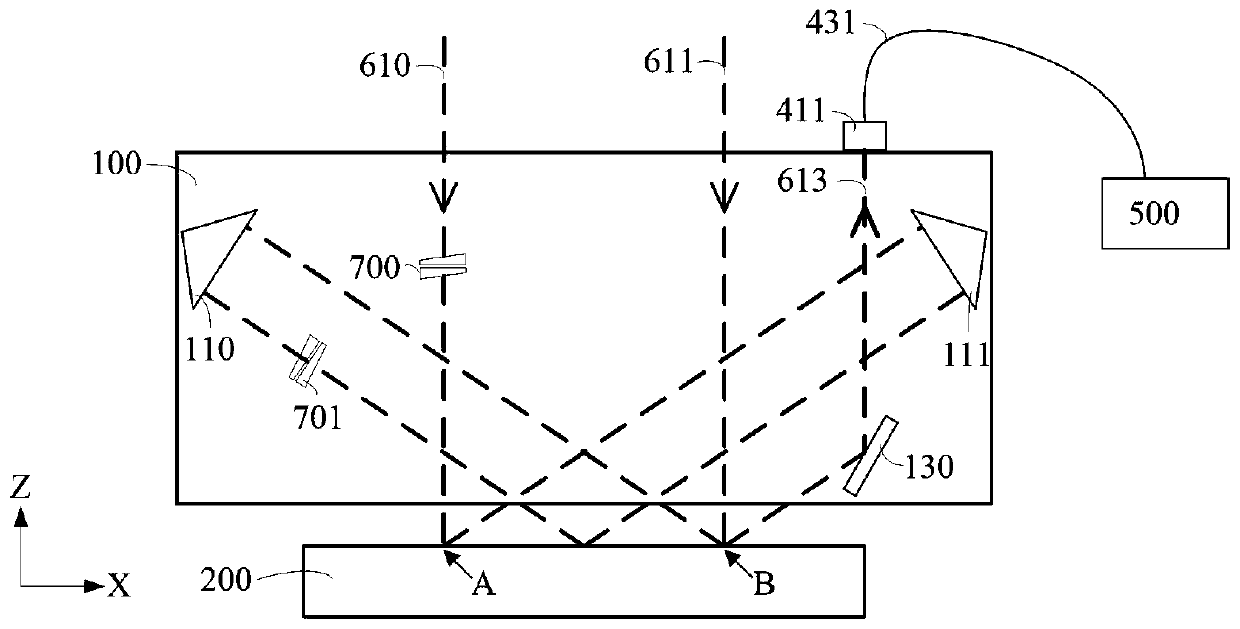

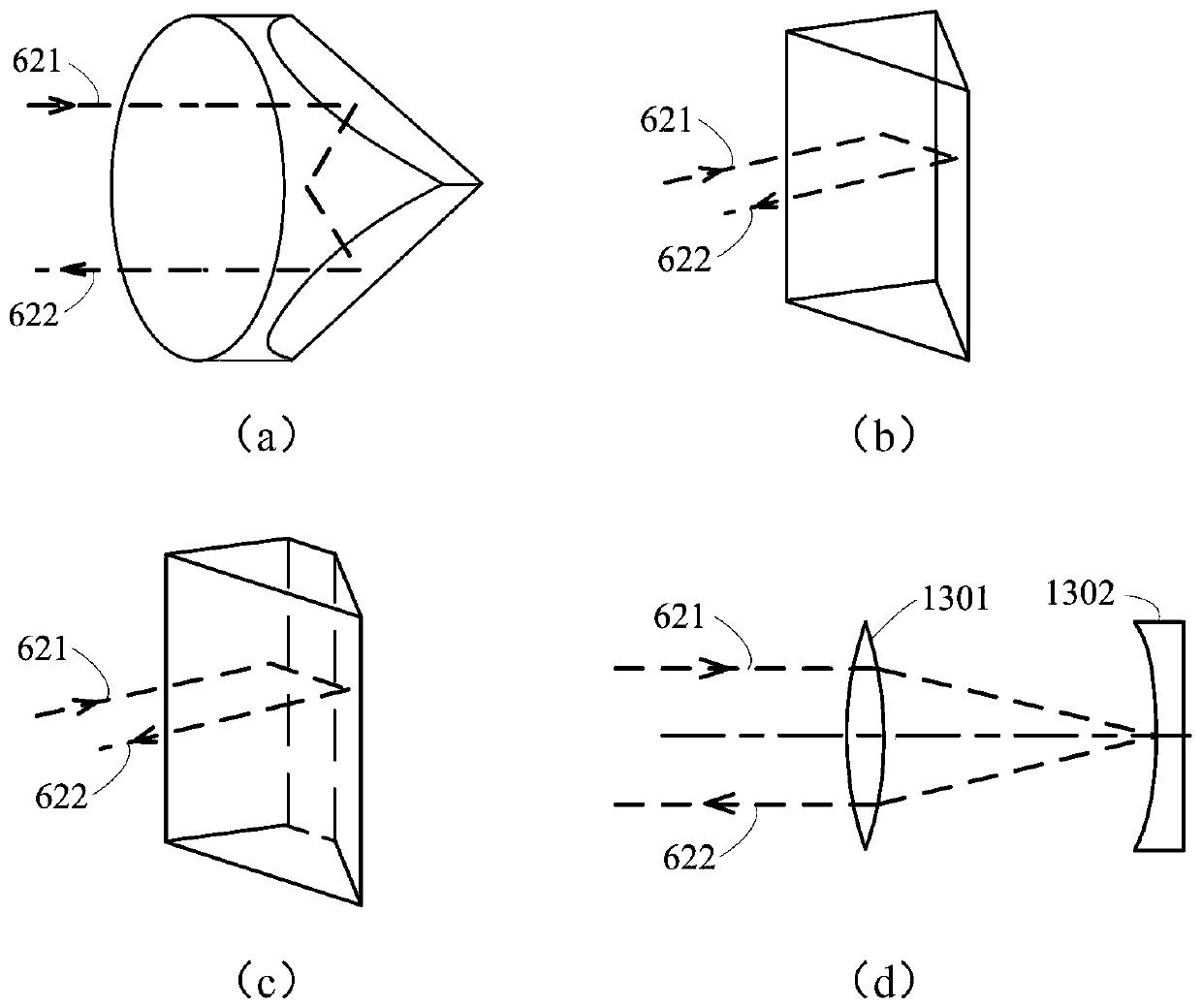

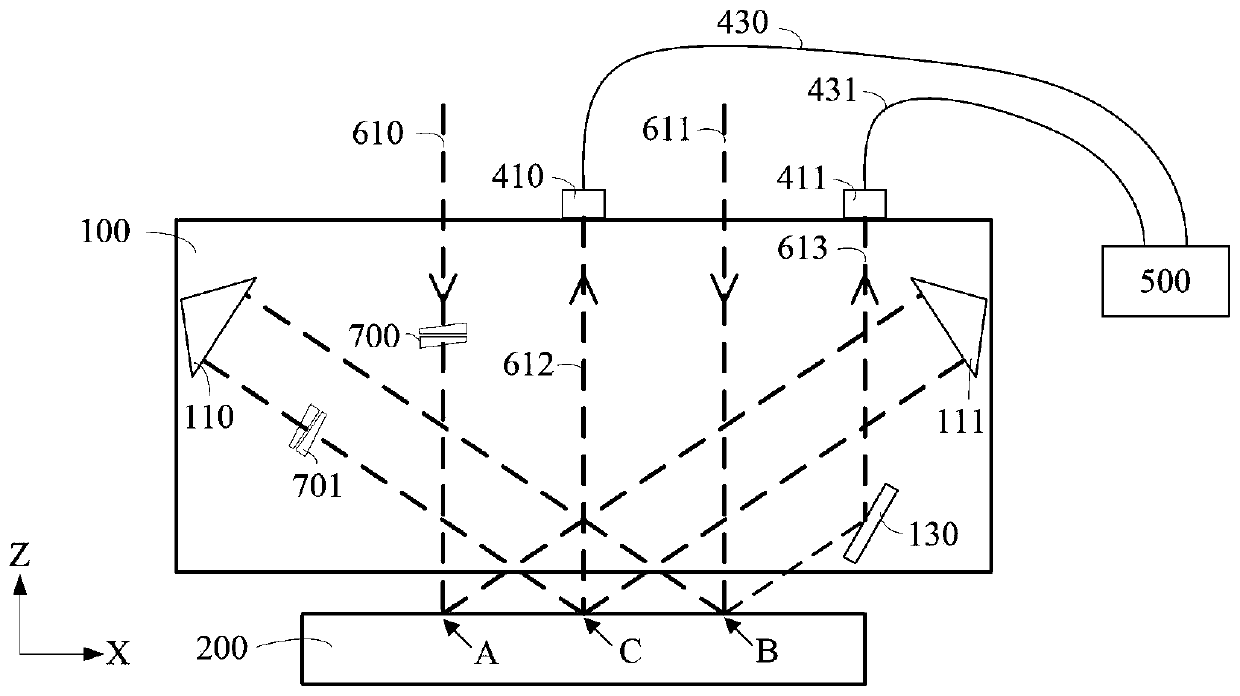

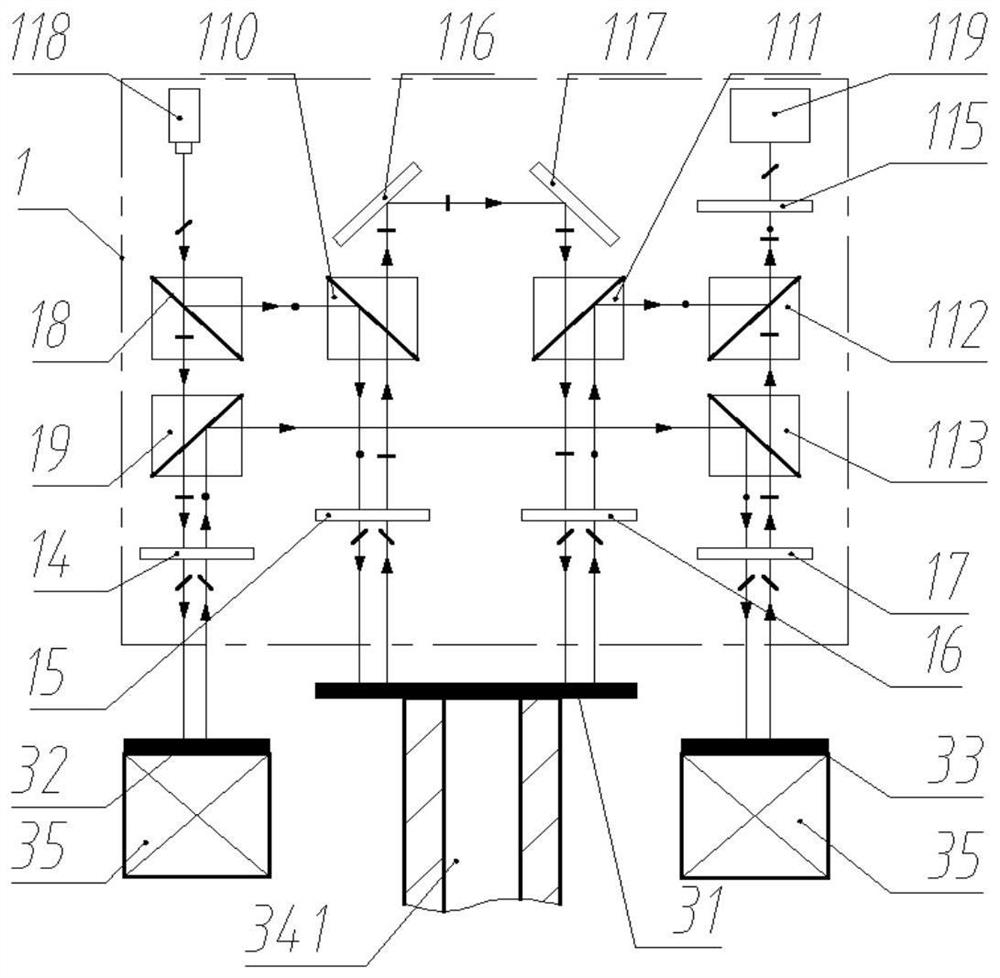

Displacement measuring device, displacement measuring method and photoetching equipment

ActiveCN111457843AReduced impact strengthReduce installationPhotomechanical apparatusReflex reflectorsLight spotLight beam

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

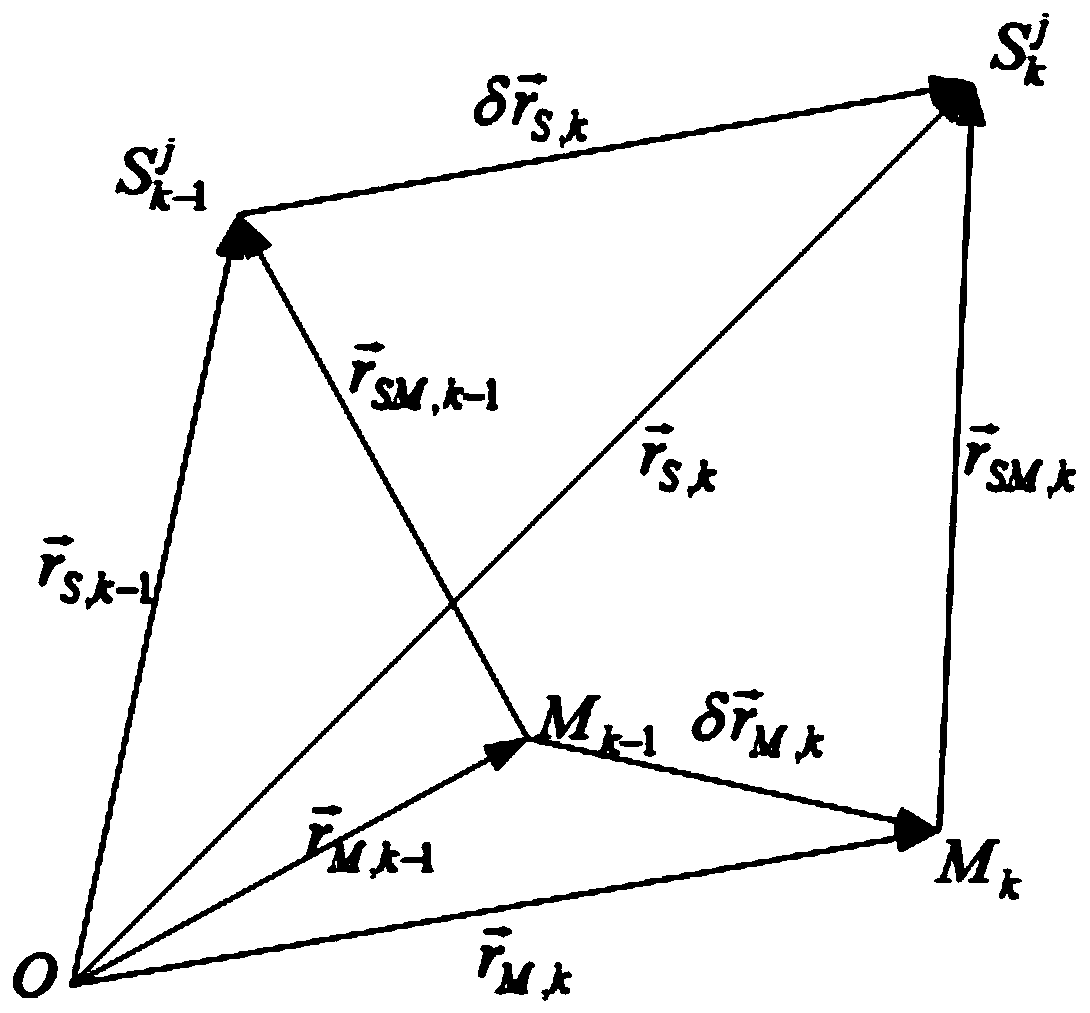

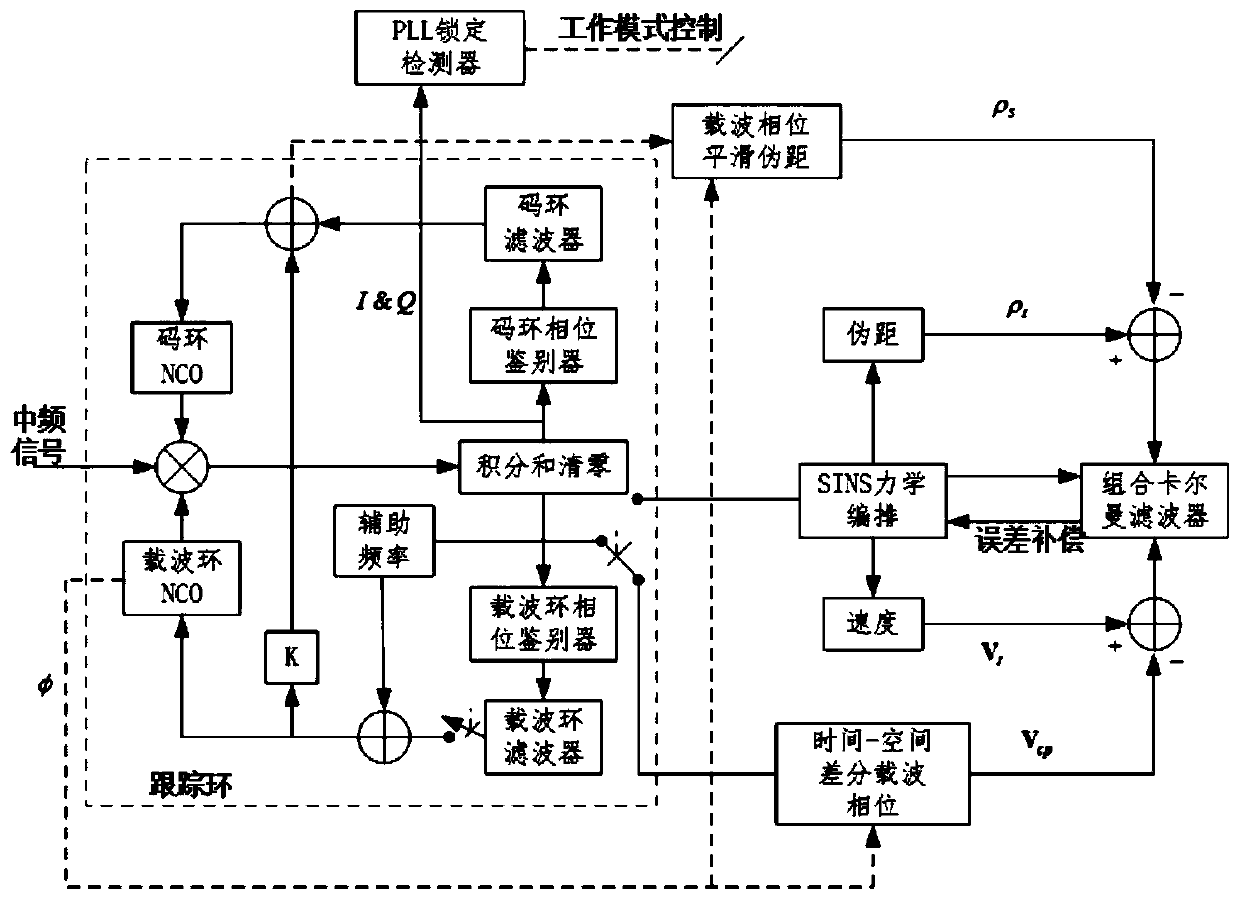

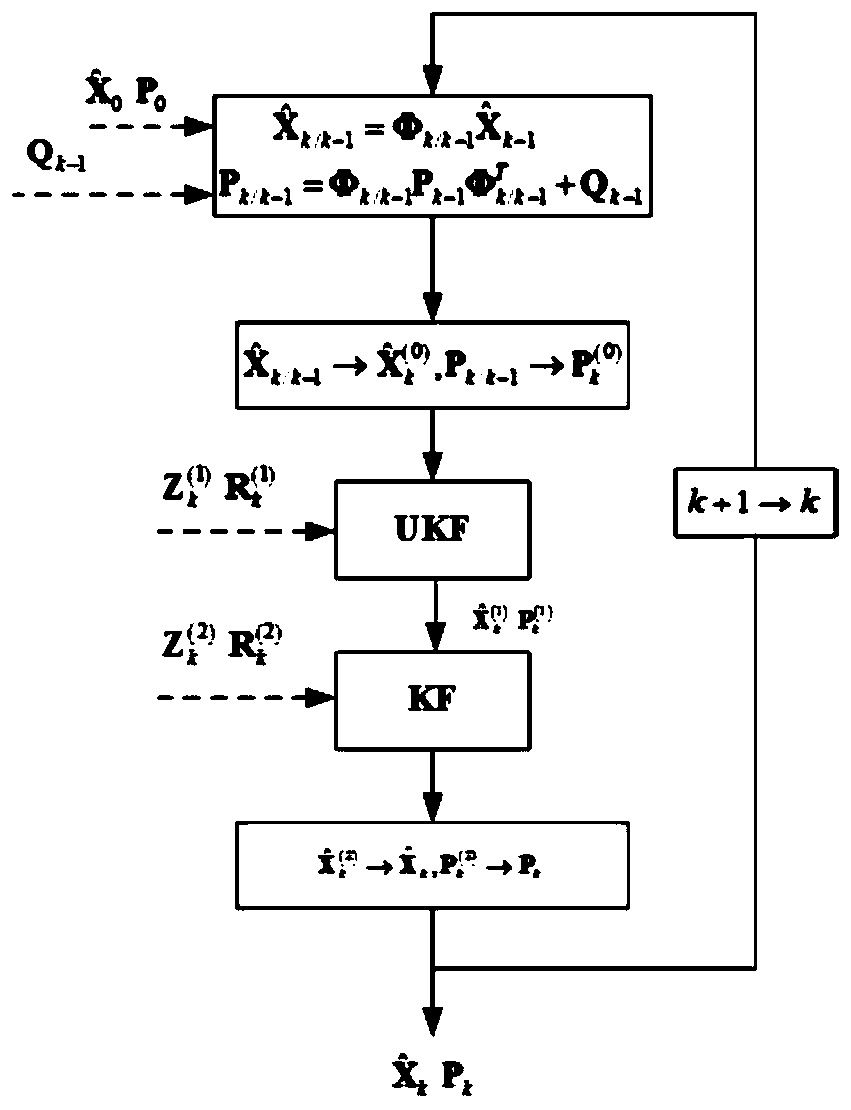

Method for designing MINS/GPS ultra-tight integrated navigation system

ActiveCN111580144AAvoid Doppler Assist ErrorImprove dynamic performanceNavigation by speed/acceleration measurementsSatellite radio beaconingSimulationNavigation system

The invention provides a MINS / GPS ultra-tight integrated navigation system design method. The method comprises the following steps of carrying out time-space difference by using carrier phase measurement to obtain a measurement equation, calculating Doppler frequency shift, assisting a GPS carrier tracking loop PLL, smoothing a pseudo-range outputted by a GPS by using carrier phase measurement, and carrying out Taylor expansion of the pseudo-range; and taking the obtained pseudo-range difference and speed difference as measurement of a system model, designing a combined Kalman filter to estimate a system state, correcting inertial device errors and the strapdown inertial navigation calculation navigation information by utilizing a state estimation result outputted by the Kalman filter, andtaking the corrected strapdown inertial navigation calculation information as the navigation positioning result. The method is advantaged in that the Doppler auxiliary errors caused by low-precisionSINS are avoided, correlation between GPS measurement errors and SINS speed errors is avoided, dynamic performance, the anti-interference capability and the navigation positioning precision of the system are enhanced, and non-linear errors introduced by linear pseudo-range measurement are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

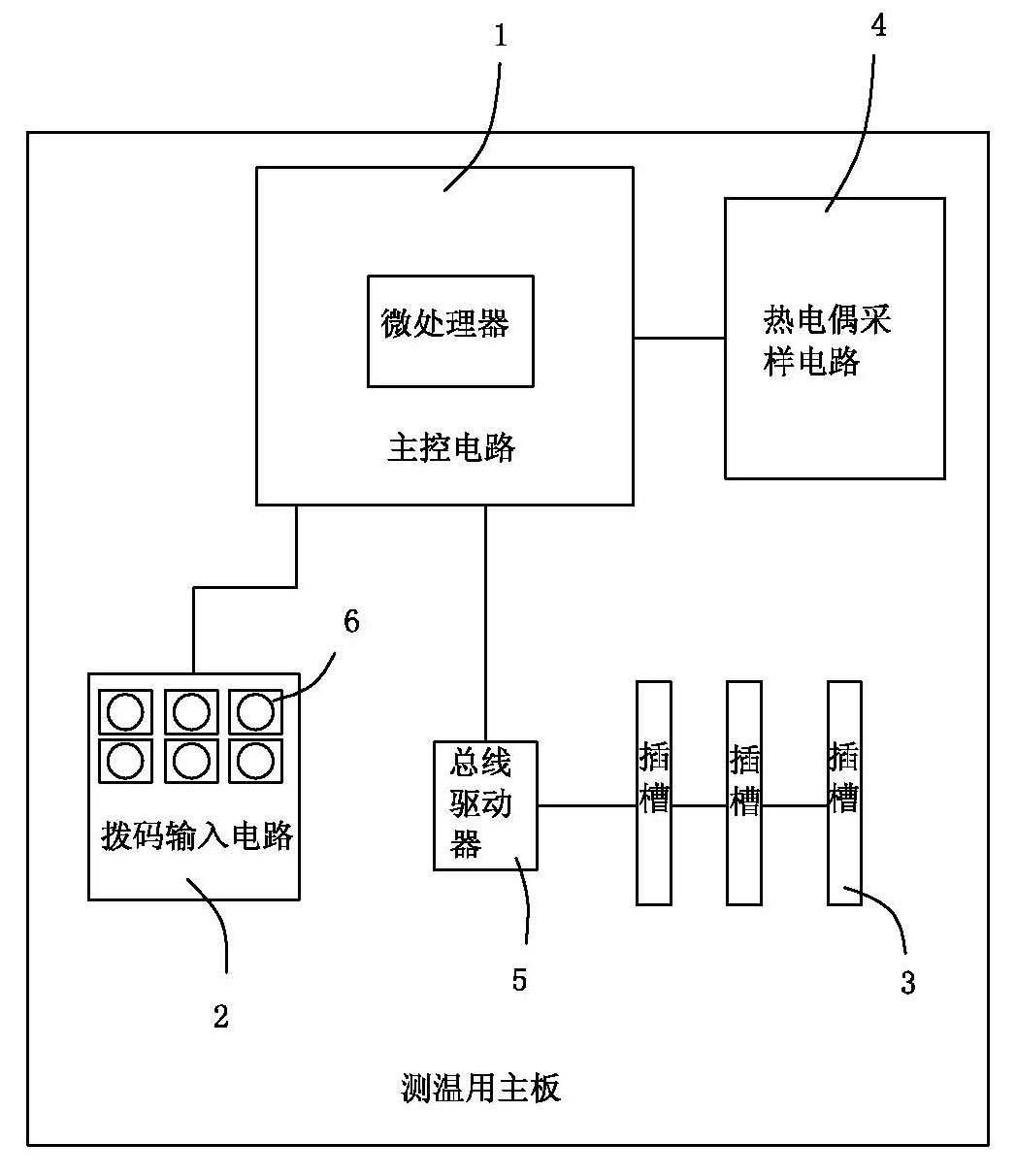

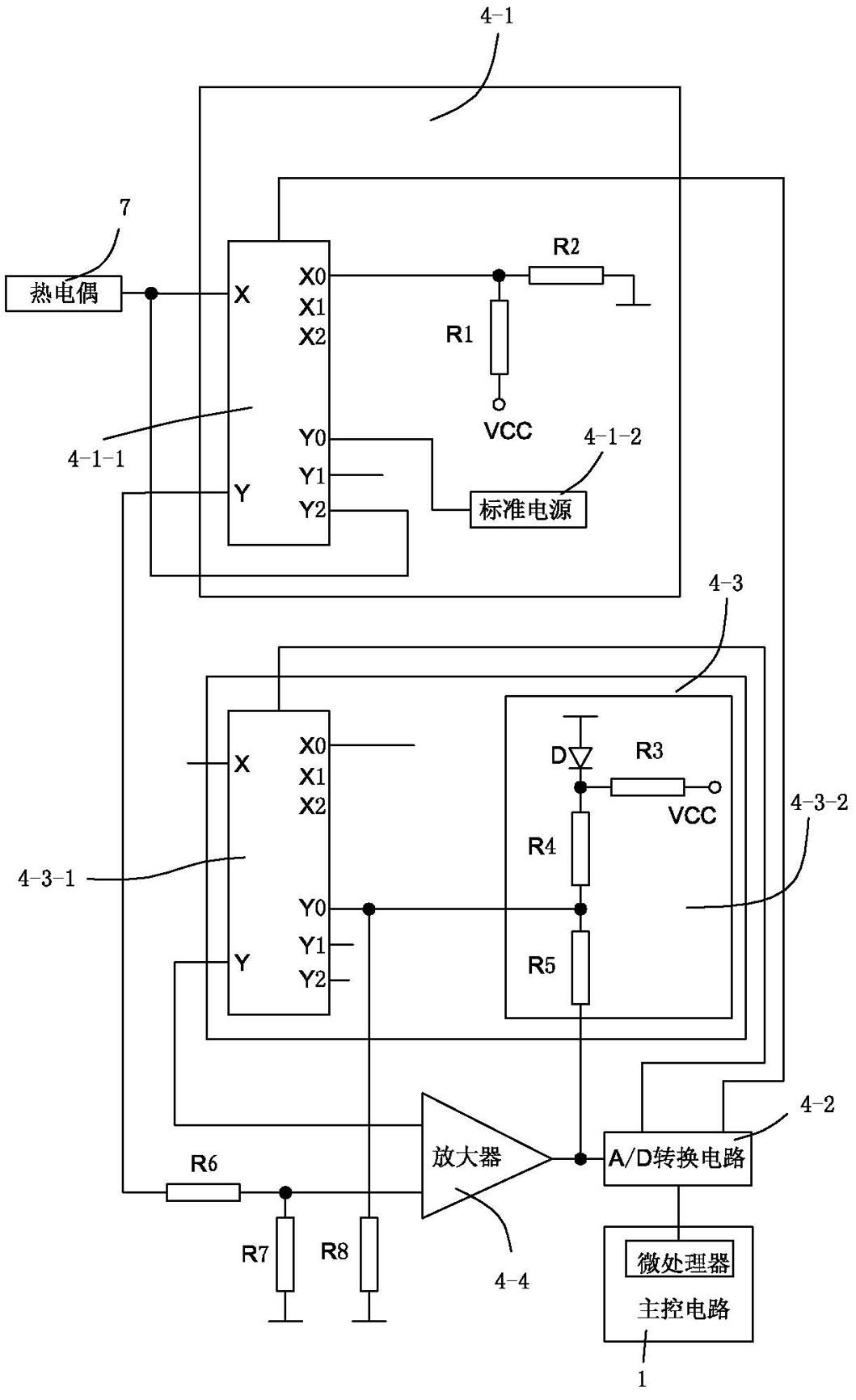

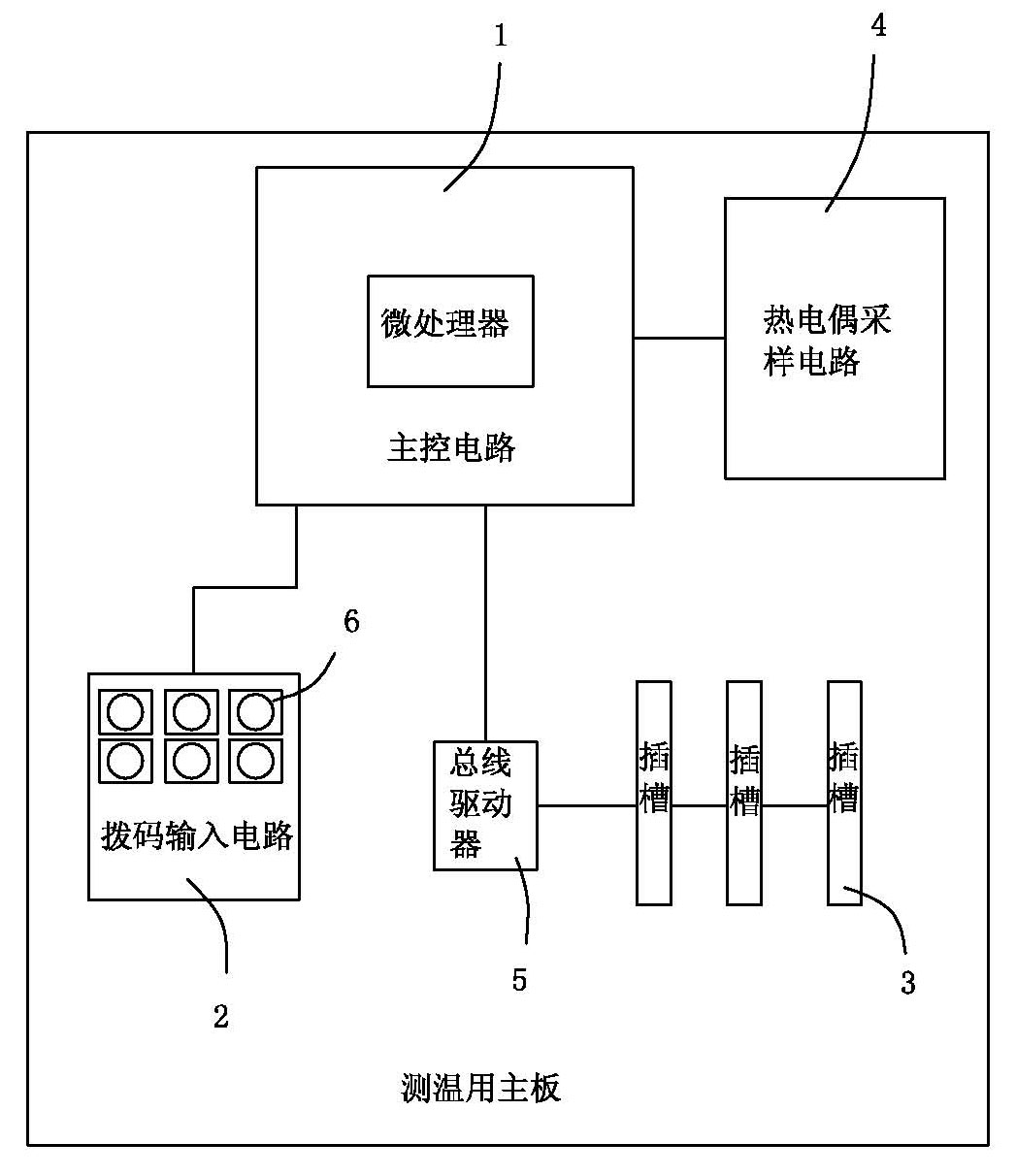

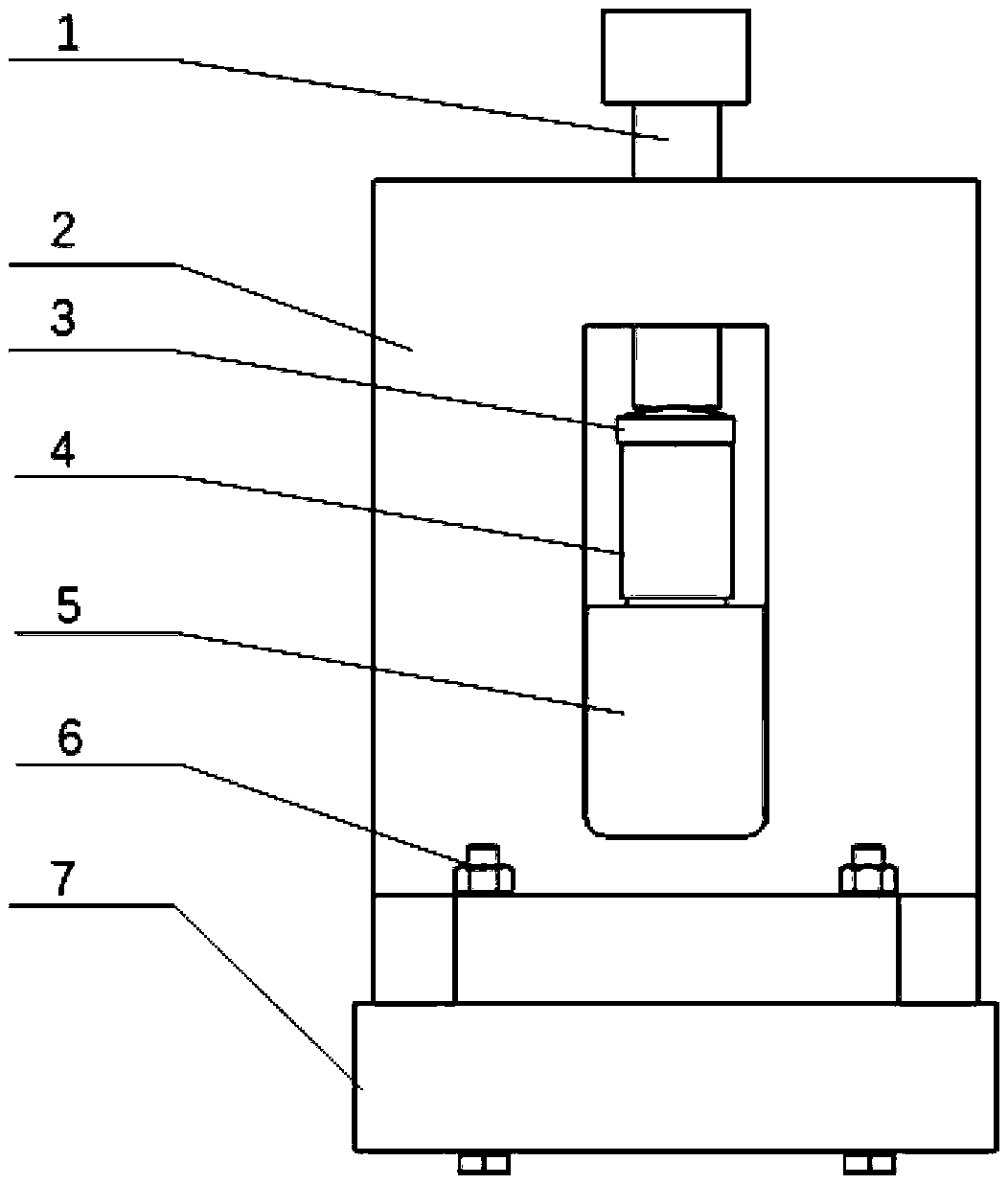

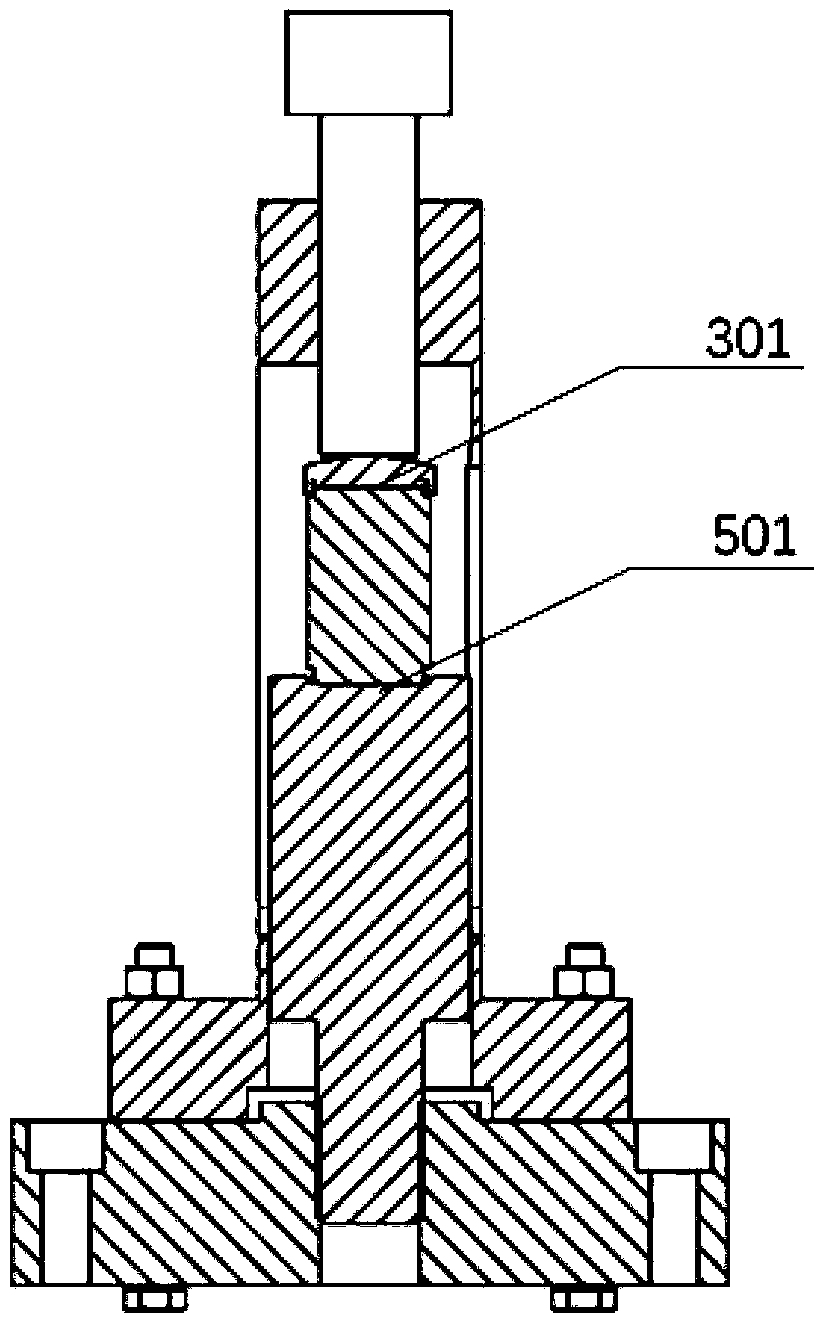

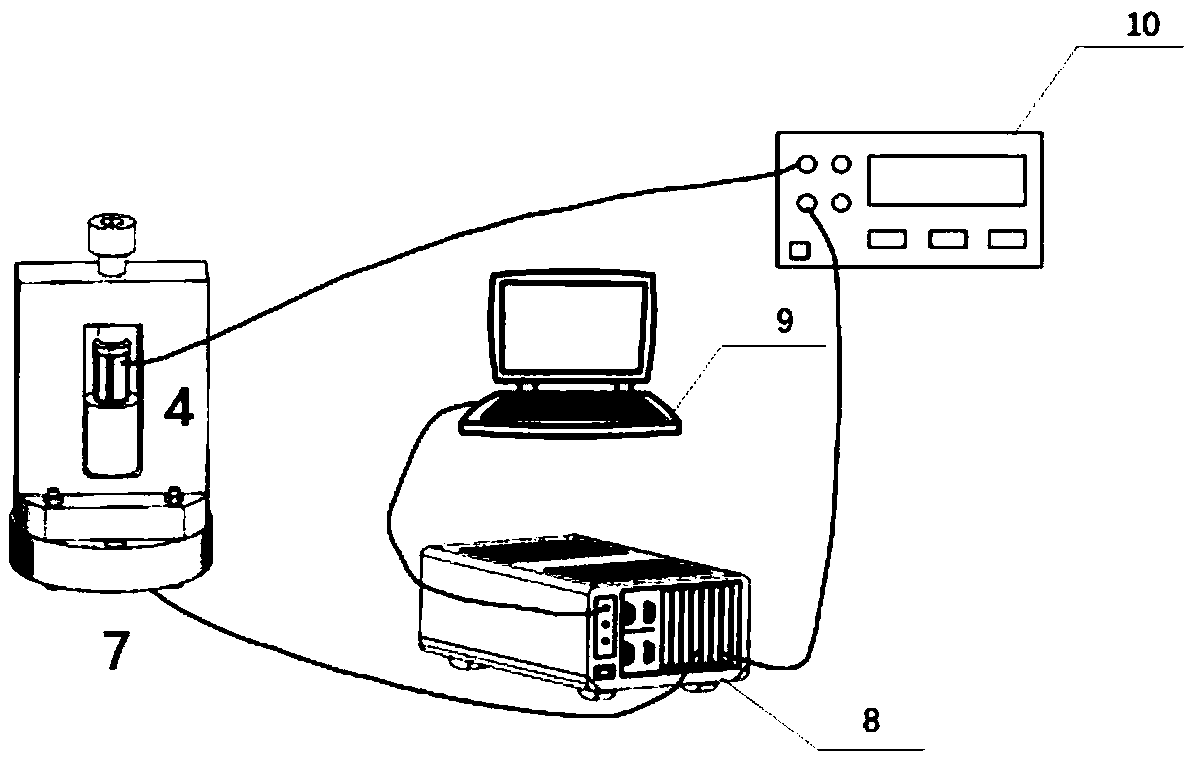

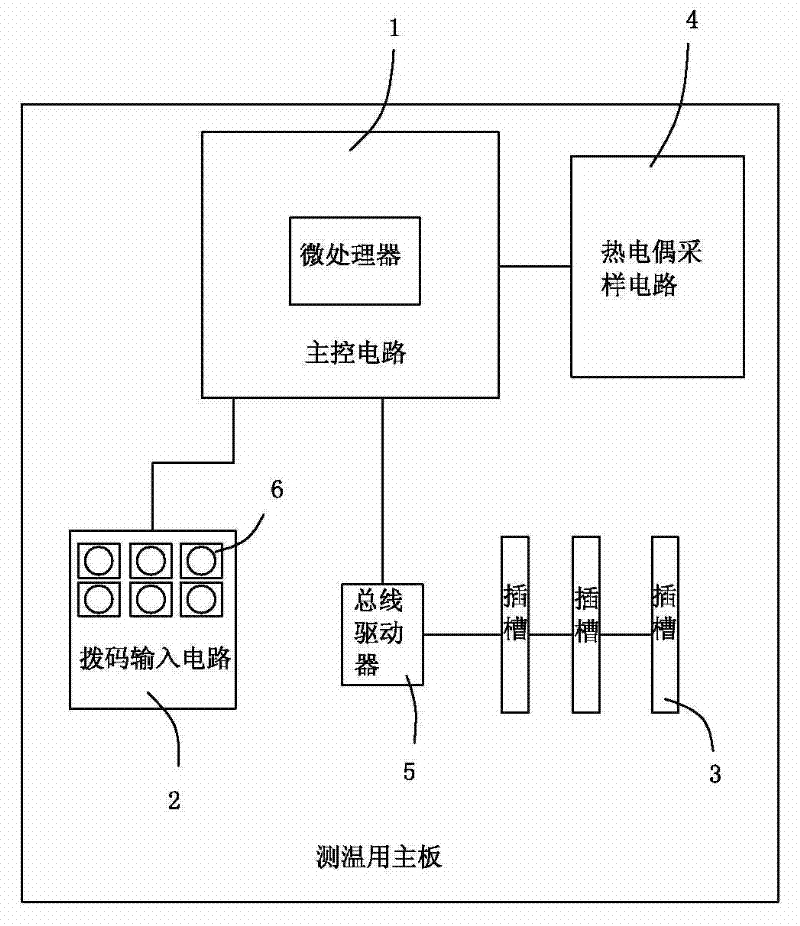

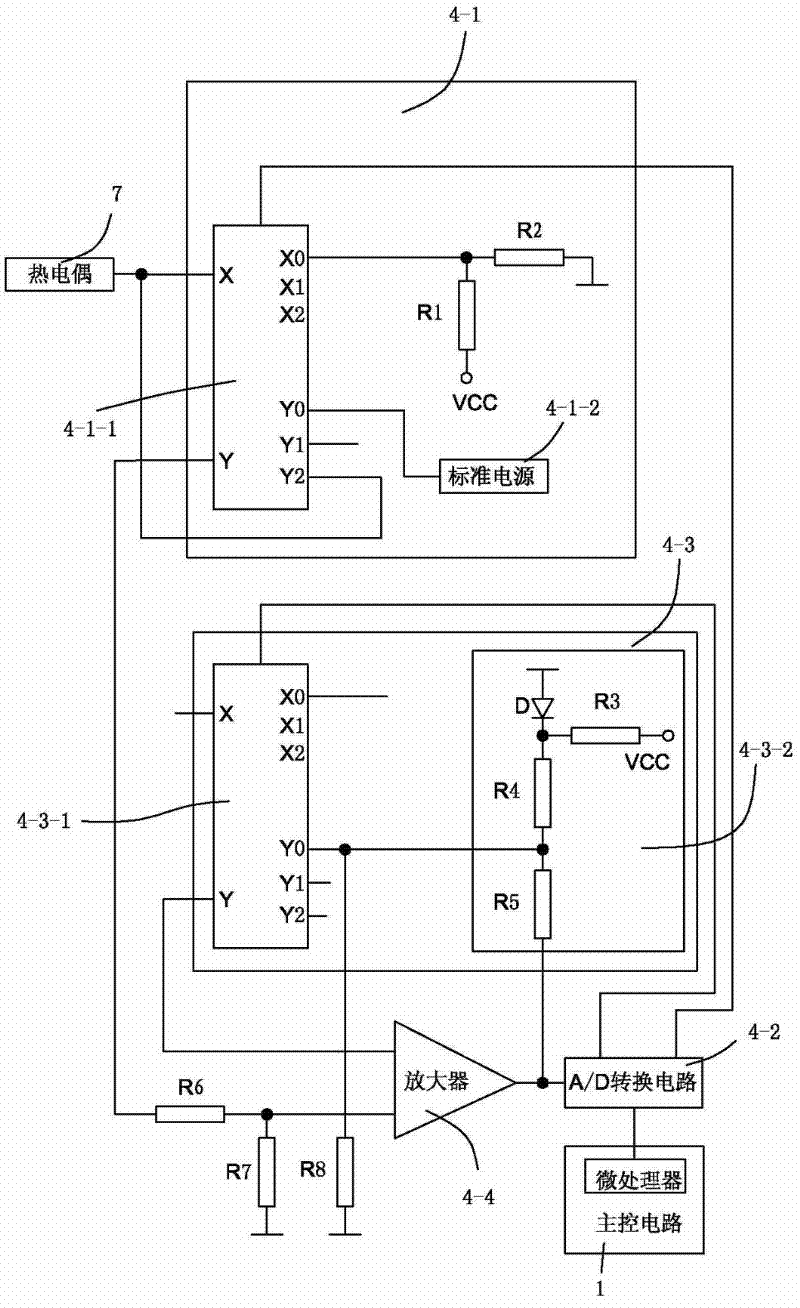

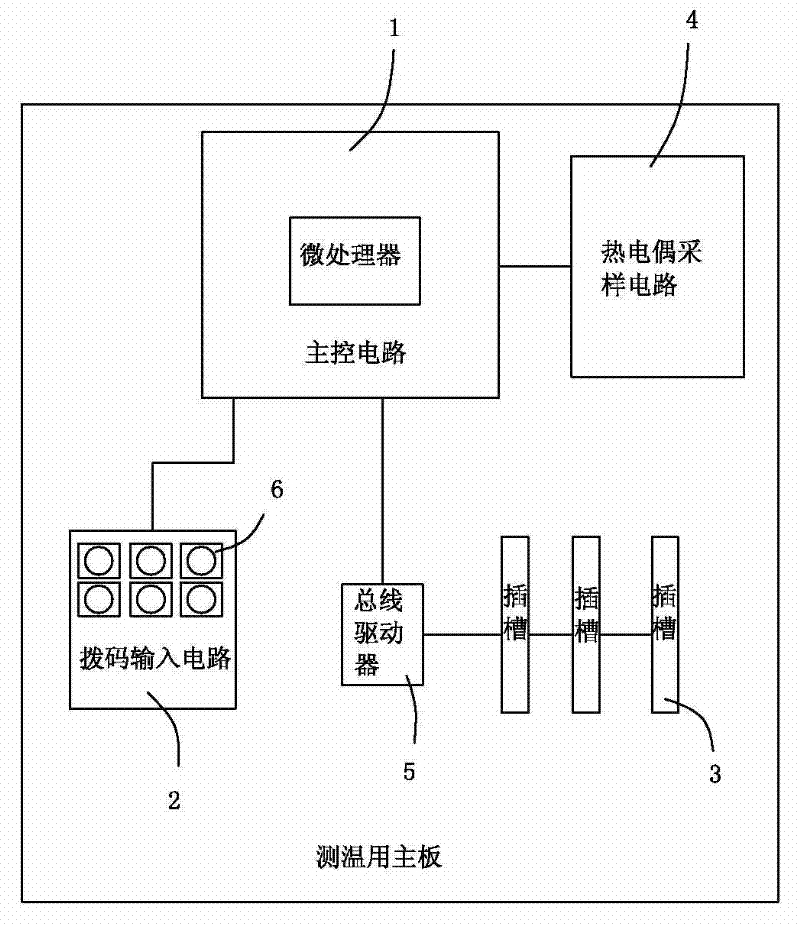

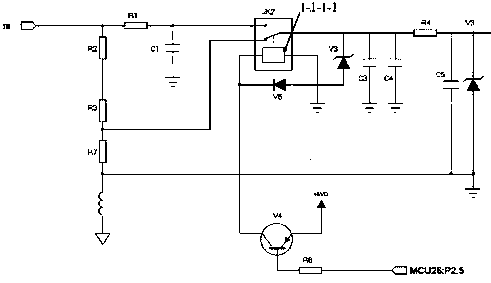

Main board for thermometer and thermocouple precision correcting method

InactiveCN101846558AReduce distractionsImprove reliabilityThermometers using electric/magnetic elementsUsing electrical meansHemt circuitsLinearity error

The invention relates to a main board for a thermometer and a thermocouple precision correcting method; the main board comprises a main control circuit consisting of a microprocessor, a dial-up input circuit, an interface circuit with at least two slots and a thermocouple sampling circuit; the invention controls the line structure of the sampling circuit with an A / D conversion circuit, reduces the line interference between digital and analog circuits, adds a zero calibration compensation circuit on the front end of the A / D conversion circuit and improves the accuracy of temperature measurement; the invention has the benefits that a bus-type interface circuit is adopted, and a plurality of interface circuit sockets are arranged to realize the extendibility of functions; the A / D conversion circuit is connected with the control end of the analog circuit, thereby reducing the connecting lines between the digital and the analog circuits, reducing the interference of the analog circuit to the digital circuit, and improving the work reliability; and the invention adds the zero calibration compensation circuit, so that when a zero point tends to be negative, the adjustment is very convenient, thereby preventing nonlinear zero-crossing error, and improving the accuracy of temperature measurement.

Owner:北京市科海龙华工业自动化仪器有限公司

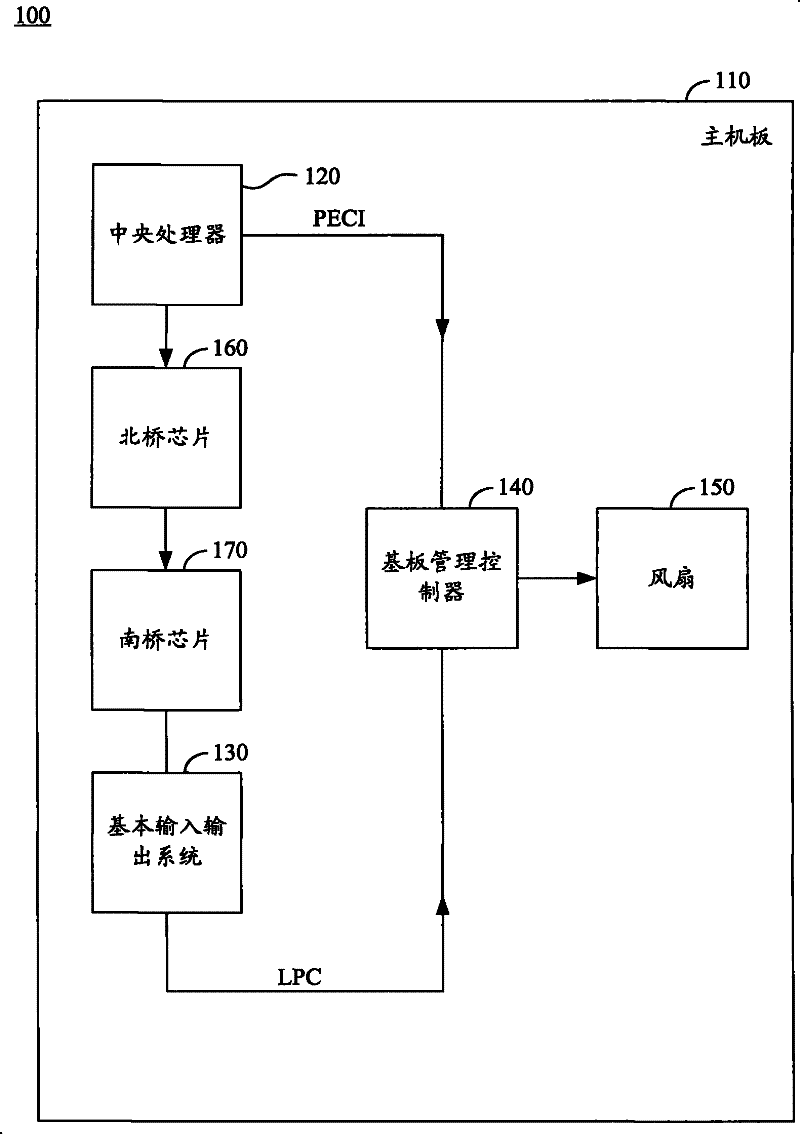

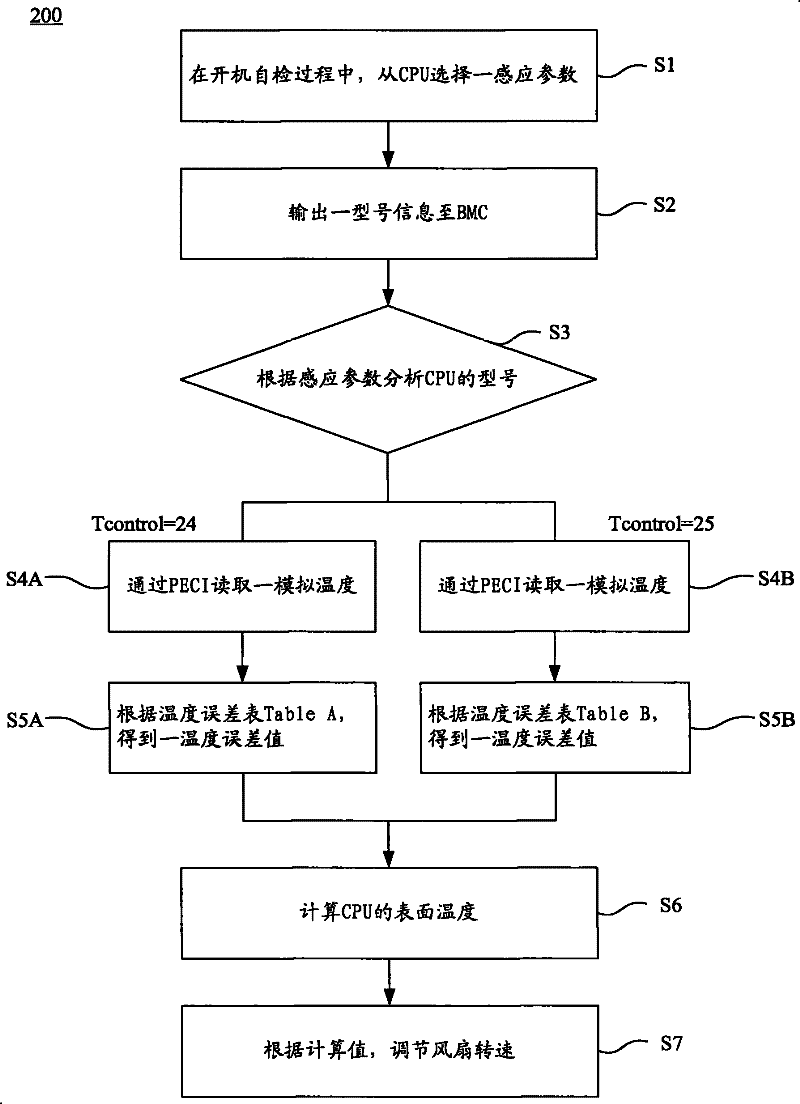

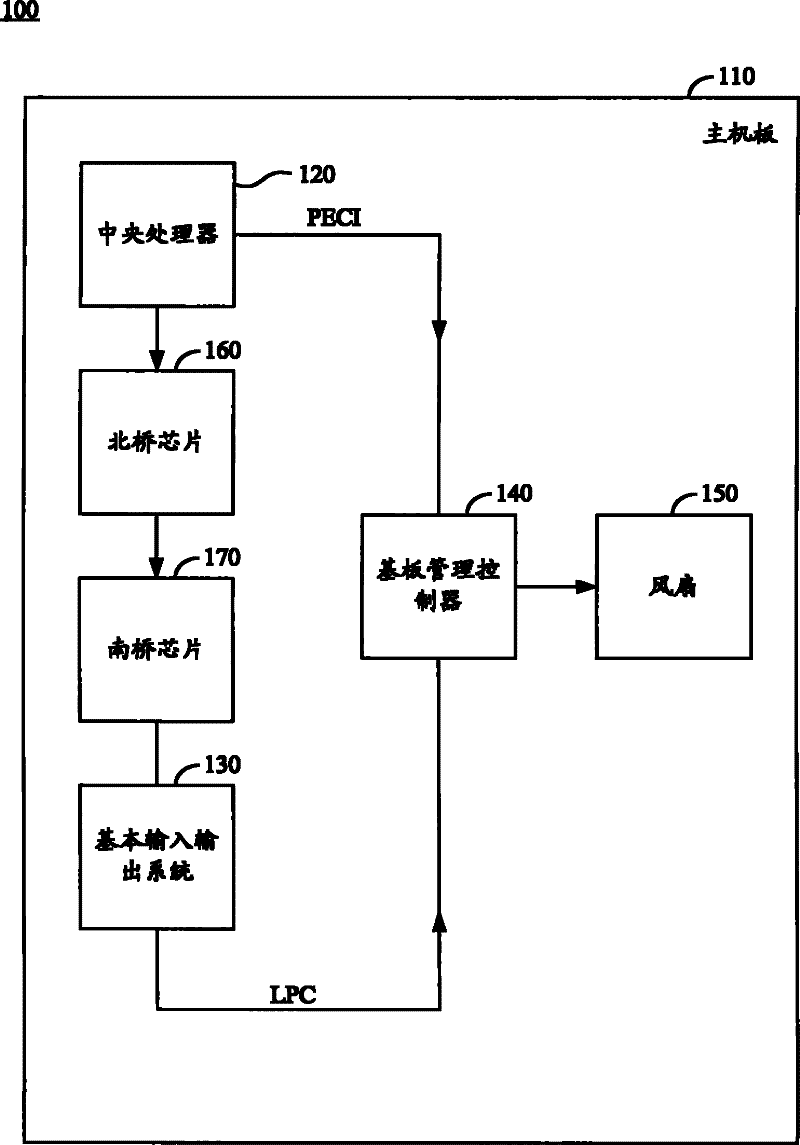

Temperature control system and operating method thereof

InactiveCN102193606AAvoid nonlinear errorsImprove temperature control safetyDigital data processing detailsTemperature controlControl system

The invention provides a temperature control system and an operating method thereof. The temperature control system comprises a main board, and the main board consists of a CPU (Central Processing Unit), a BIOS (Basic Input / Output System), a base board management controller and a fan. The BIOS detects the CPU and outputs model information in a power-on self-test process. The operation method of the temperature control system comprises the following steps: the base board management controller reads analogue temperature from the CPU; the BIOS stores at least one temperature error list; the base board management controller selects a corresponding temperature error list according to the model information and calculates the surface temperature of the CPU according to the temperature error list and analogue temperature compensation so as to output a control signal; the fan receives the control signal and runs based on the control signal to reduce the surface temperature of the CPU. By utilizing the system and method disclosed by the invention, nonlinear errors between the analogue temperature and a practical temperature can be completely eliminated, thus the safety of the temperature control of the CPU can be largely improved, and the stability of the operation of a whole system can be enhanced.

Owner:INVENTEC CORP

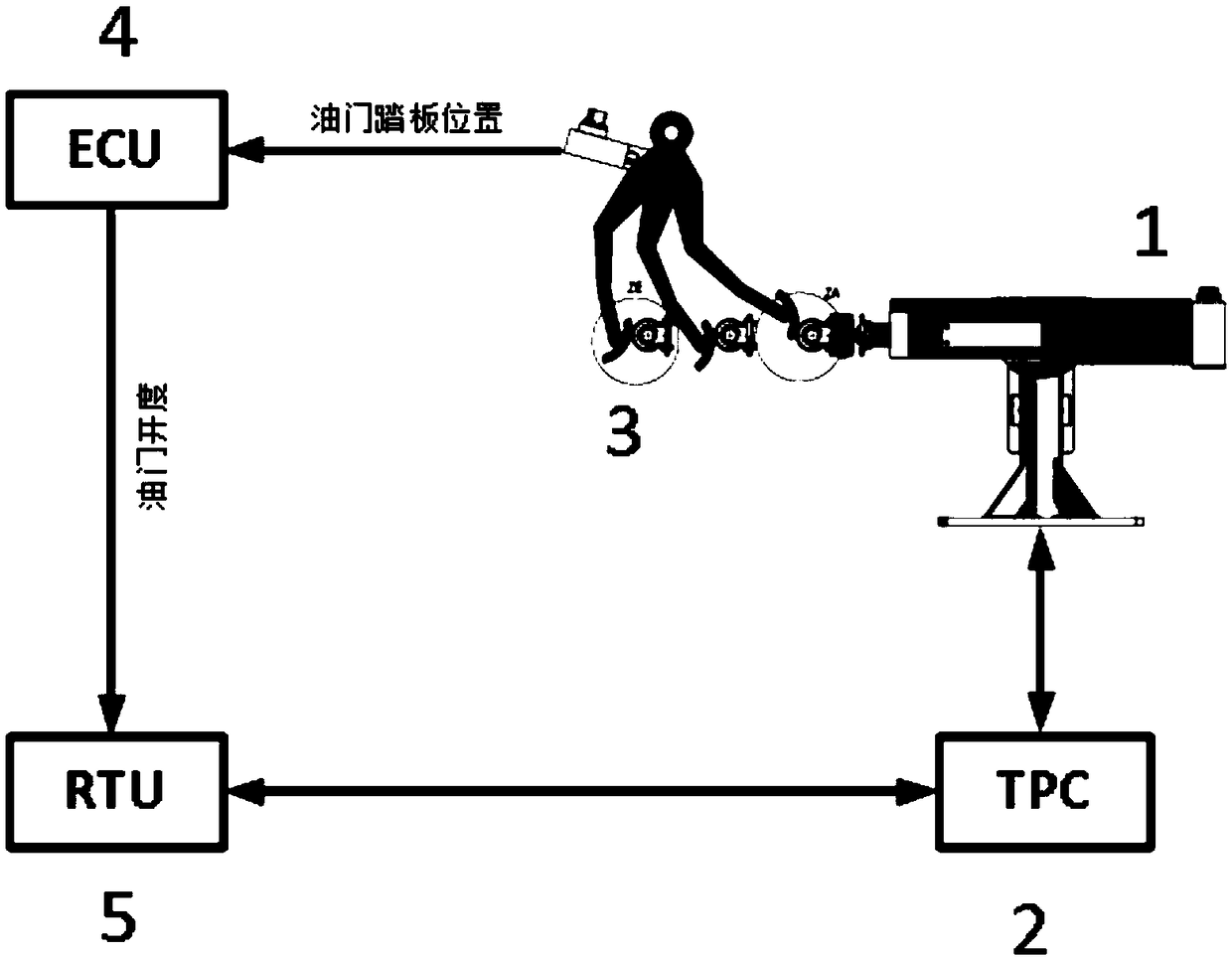

Throttle correction method for power assembly test rack

InactiveCN108958069AReduce loadSimple methodProgramme control in sequence/logic controllersCurve fittingRepeatability

The invention discloses a throttle correction method for a power assembly test rack. According to the method, a table look-up method instead of a curve fitting method is employed to perform throttle correction to obtain higher control precision. The method has the advantages that: (1) the method is simple, no complicated algorithm is needed, and the load of an RTU is reduced, (2) nonlinear errorsof a throttle pedal and machines are overcome and the control precision is high, and (3) values are separately taken in releasing and pressing the throttle pedal and the disadvantage of poor repeatability of the throttle pedal is overcome.

Owner:GIF RES CENT CHINA

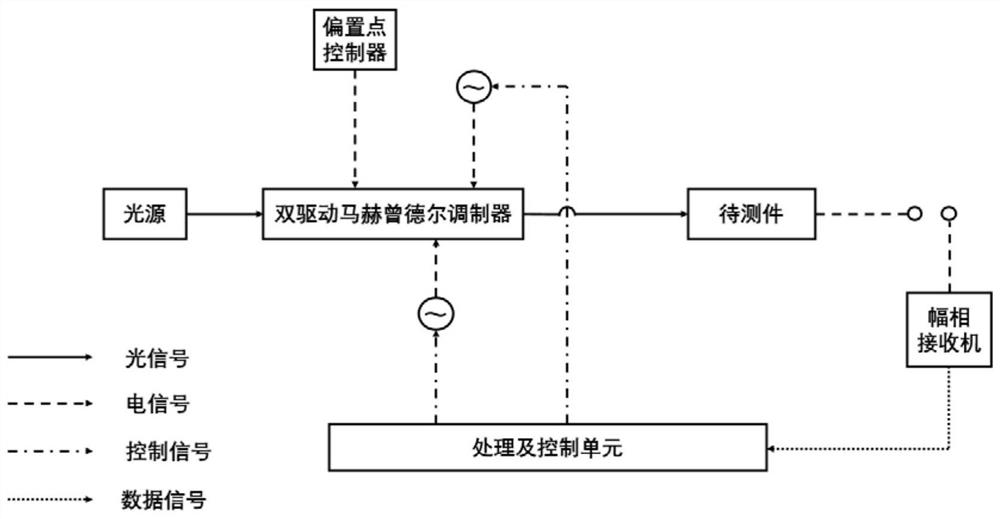

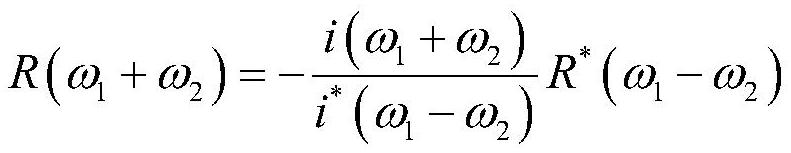

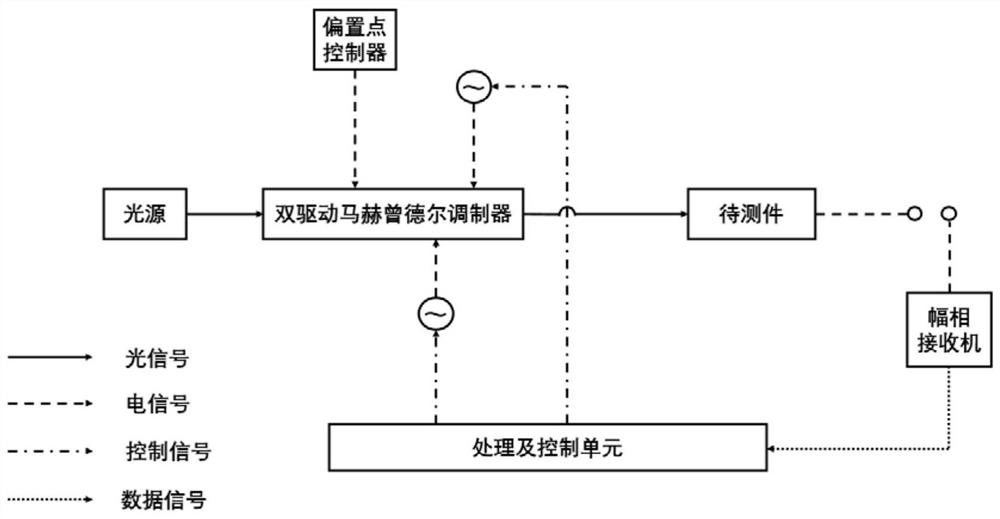

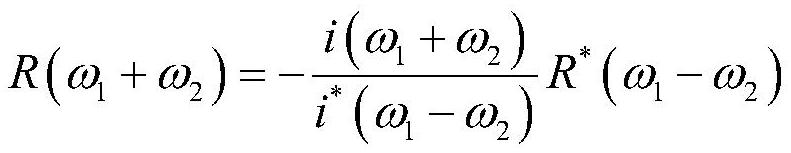

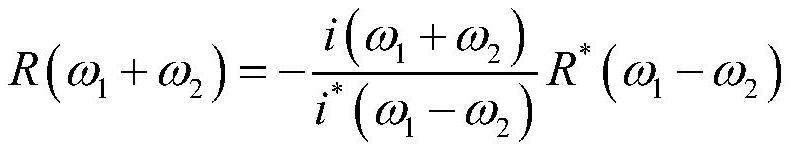

Photoelectric detector frequency response measurement method and device based on two-tone modulation

ActiveCN113341222AReduce frequency requirementsHigh resolutionSpectral/fourier analysisOptical apparatus testingPhase responsePhotovoltaic detectors

The invention discloses a photoelectric detector frequency response measurement method based on two-tone modulation, which comprises the following steps of: modulating two paths of microwave signals with different frequencies omega1 and omega2 on the same path of optical carrier to generate an optical double-sideband signal for suppressing the carrier; and converting the carrier-suppressed optical double-sideband signal into an electric signal by using a photoelectric detector to be detected, extracting an up-conversion signal component and a down-conversion signal component in the electric signal, and calculating the amplitude-phase response of the photoelectric detector to be detected according to the up-conversion signal component and the down-conversion signal component. The invention further discloses a photoelectric detector frequency response measurement device based on two-tone modulation. Compared with the prior art, measurement errors introduced in the measurement process can be effectively reduced, the measurement accuracy is improved, and the dynamic range is widened.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Device and method for calibrating flow-dividing vacuum leaking hole

ActiveCN101713696BWide measurement rangeReduce measurement uncertaintyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateVacuum pumpingEngineering

The invention relates to a device and a method for calibrating a flow-dividing vacuum leaking hole, in particular to the device and the method for calibrating the vacuum leaking hole, the leakage value of which is less than 1*10-8 Pa.m3 / s by adopting flow-dividing technology, and belongs to the field of measuring technology. The device consists of the calibrated leaking hole, a valve, an ionization gauge, a small hole, a flow-dividing chamber, a non-evaporable getter pump, an ultrahigh vacuum calibrating chamber, a metering hole, a very high vacuum pumping chamber, an oil-free bi-turbo molecular pump air exhauster set, a quadrupole mass spectrometer, a flow meter, a super-high vacuum calibrating chamber, the metering hole, a super-high vacuum pumping chamber and a common molecular pump air exhauster set. The method adopts a fixed flow method gas micro-flow meter to provide a known gas flow rate, so the measuring range of the flow rate is wide and uncertainty of the measurement is low;and by adopting a flow-dividing method to calibrate the vacuum leaking hole, the method of the invention completely avoids a nonlinear error of the quadrupole mass spectrometer and can precisely calibrate the vacuum leaking hole the leakage value of which is less than 1*10-8 Pa.m3 / s.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

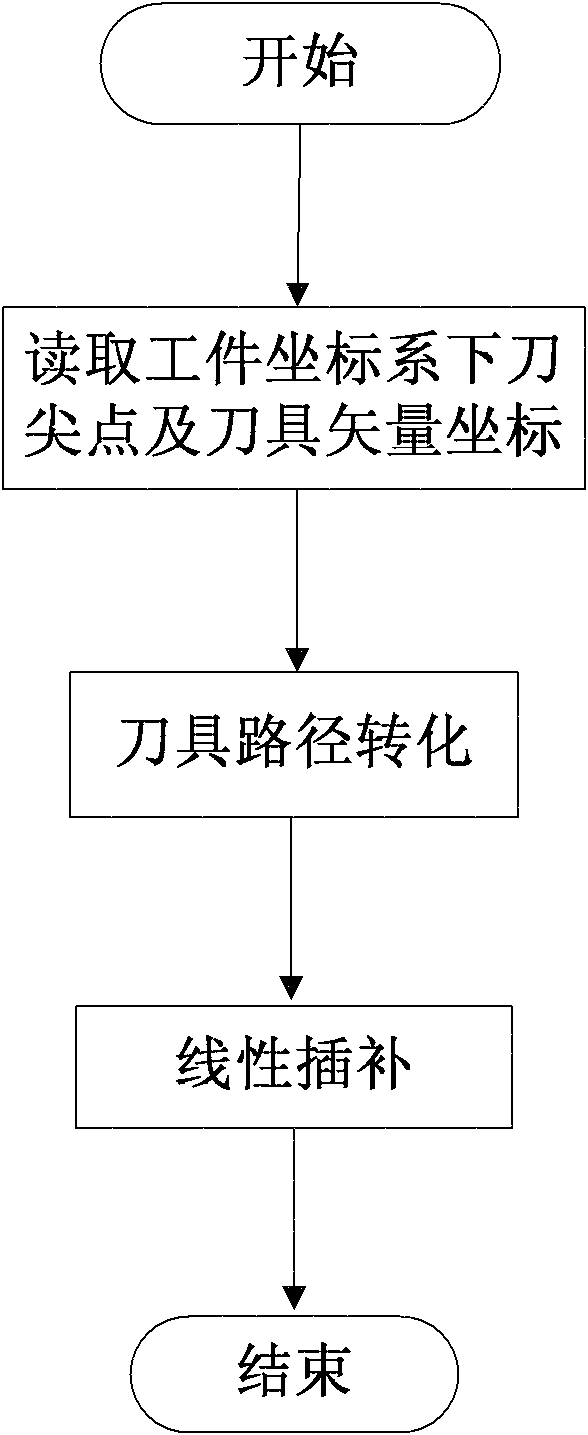

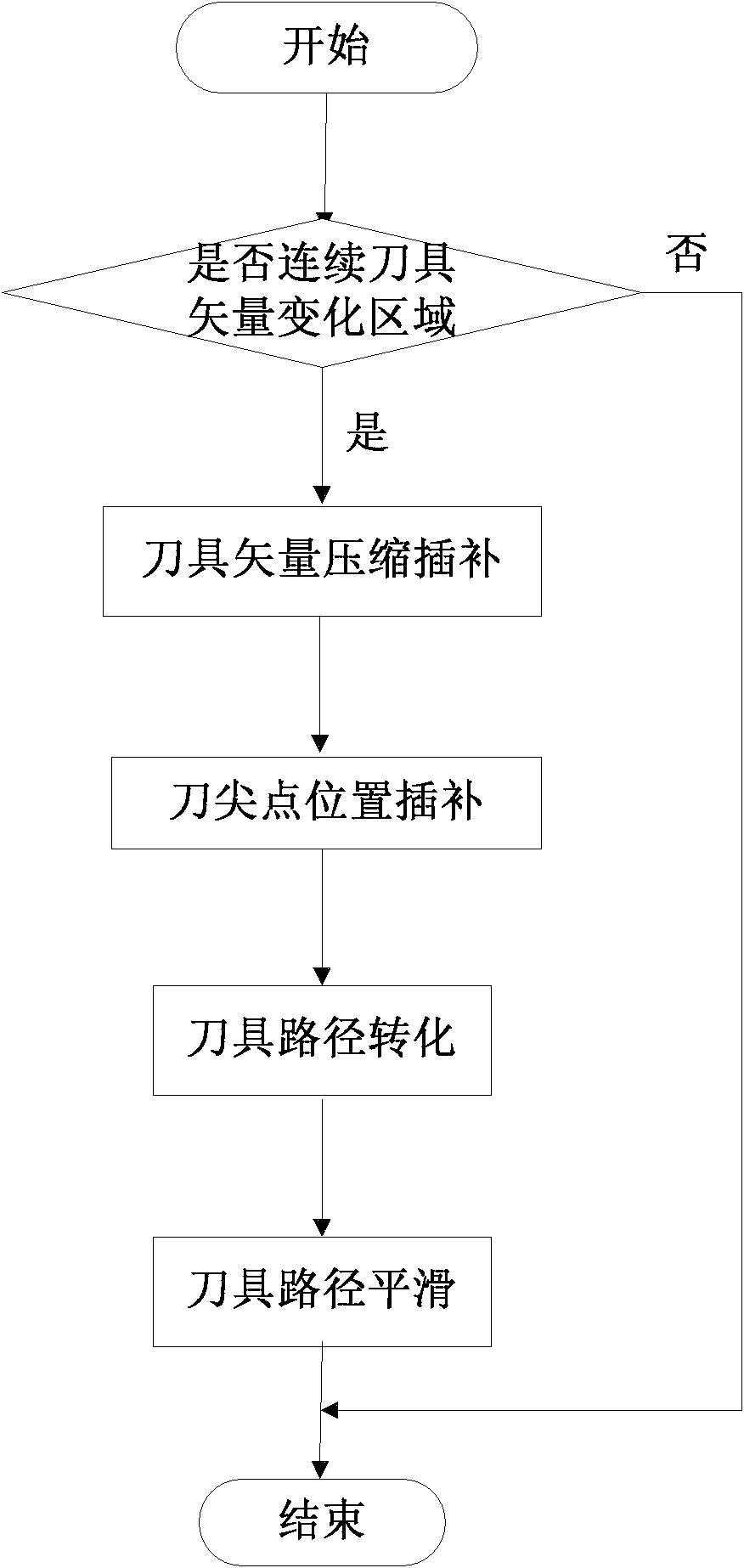

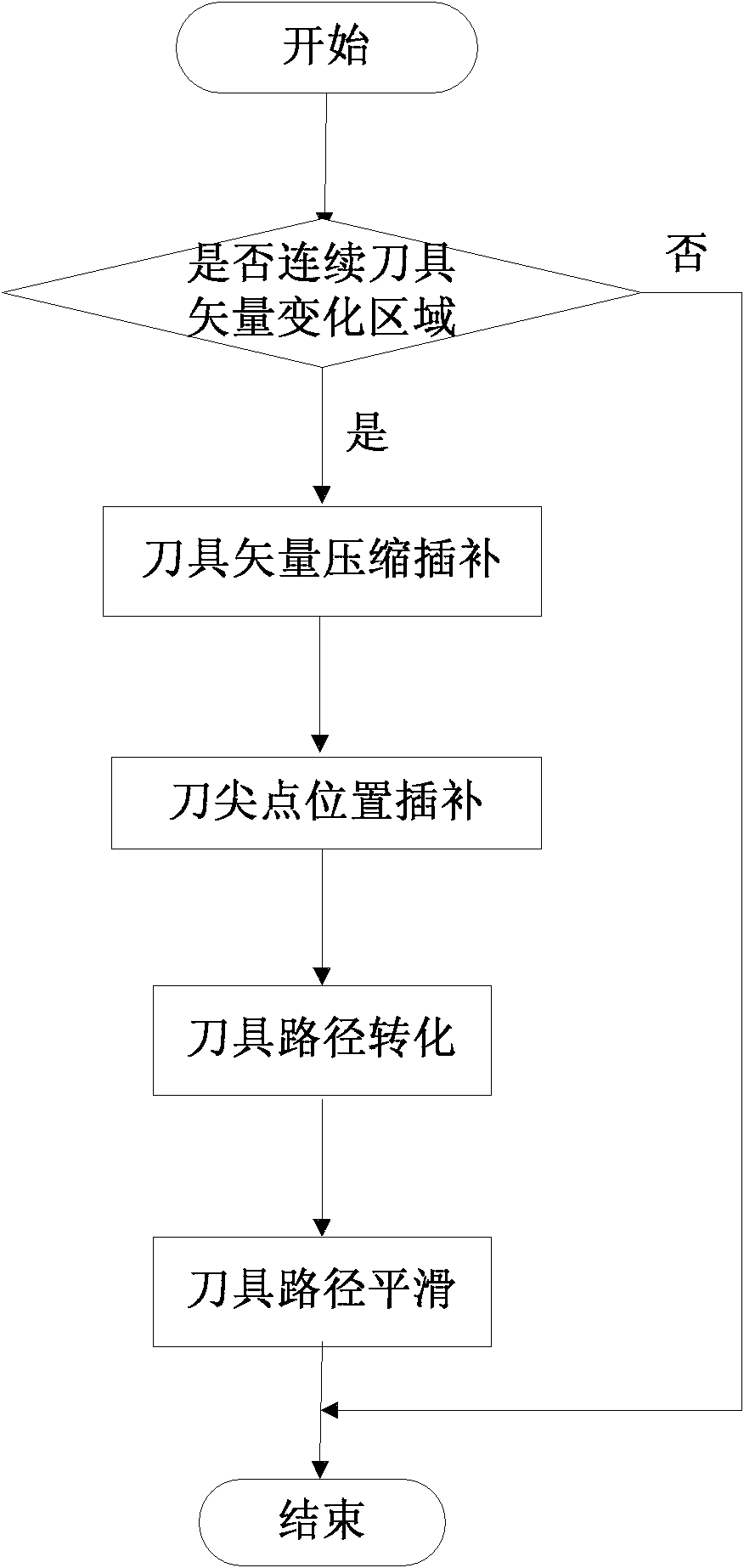

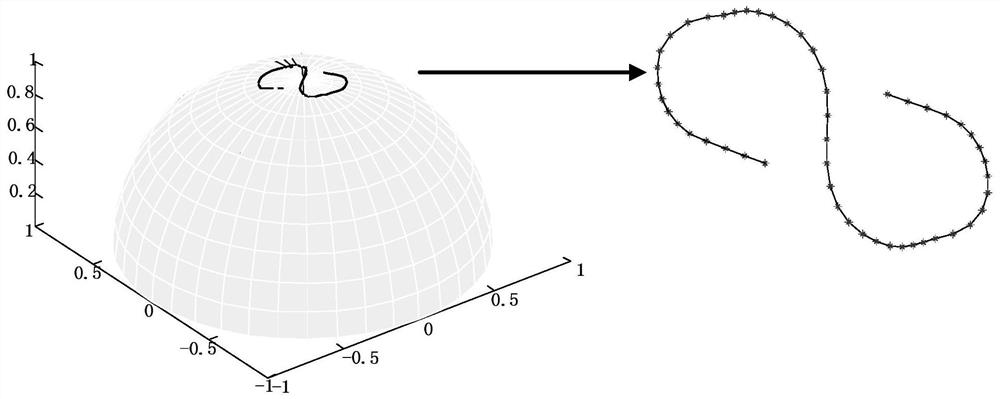

A Five-Axis NC Interpolation Method Based on Tool Vector Smooth Compression

ActiveCN102566494BGuaranteed Second Order ContinuityAvoid nonlinear errorsNumerical controlNumerical controlNose

The invention relates to a five-axis numerical control interpolation method based on smooth compression of tool vectors. The five-axis numerical control interpolation method comprises the following steps: judging whether any two adjacent tool vectors meet the conditions of continuous processing according to a read numerical control processing program; if the conditions of continuous processing are met, carrying out compression interpolation of the tool vectors and interpolation of tool nose position; transforming a tool path to transform the tool nose position and tool vector values under a workpiece coordinate system to each axis coordinate under a machine tool coordinate system by utilizing points obtained after compression interpolation of the tool vectors and interpolation of the tool nose position; and fitting two adjacent points after transformation to generate a smooth curve by utilizing a quintic polynomial curve with continuous second derivative. With the adoption of the five-axis numerical control interpolation method, second order continuity of each component of the tool vectors can be ensured, large change of the tool vectors is avoided, nonlinear error generated by dynamic change of a rotation axis in a linear interpolation method is avoided, and the processing precision is improved.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

Measurement circuit and device

PendingCN111398668AImprove linearityImprove accuracyElectrical measurement instrument detailsElectrical testingSoftware engineeringHemt circuits

The embodiment of the invention provides a measurement circuit, and the circuit comprises a first conversion circuit which amplifies an inputted current signal and carries out the current-voltage conversion; a second conversion circuit, connected to the output end of the first conversion circuit and used for carrying out single-ended-differential conversion on the input voltage signal; a third conversion circuit, connected to the output end of the second conversion circuit and used for carrying out analog-digital conversion on the input differential signal; a control circuit, connected to theoutput end of the third conversion circuit, controlling the measuring circuit and performs operation on the input digital signal; wherein the first conversion circuit comprises an amplifier and a feedback resistor bridged between the inverting input end and the inverting output end of the amplifier, and the feedback resistor enables the first conversion circuit to have a single amplification gain.By using the measurement circuit provided by the embodiment of the invention, a measurement result with higher linearity and accuracy can be obtained.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

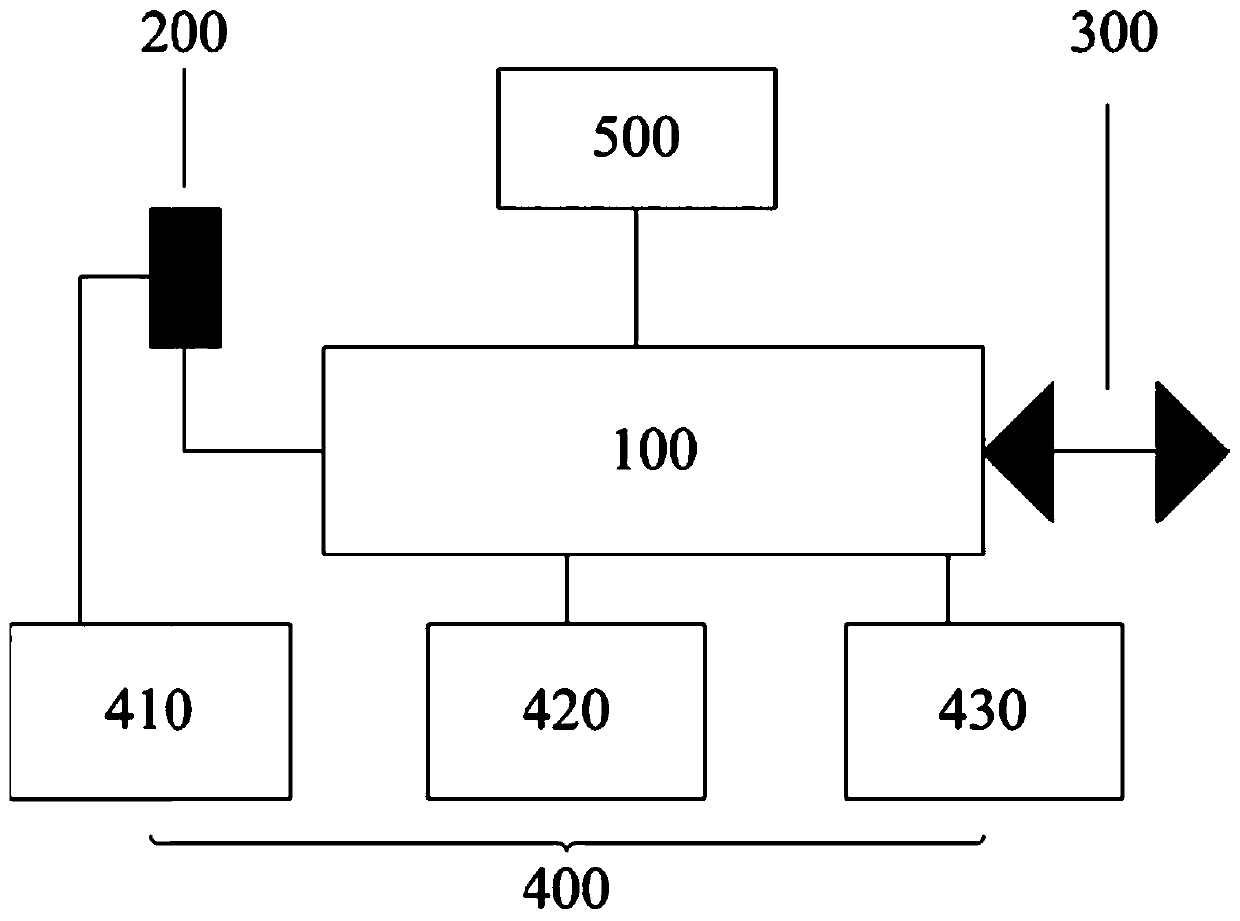

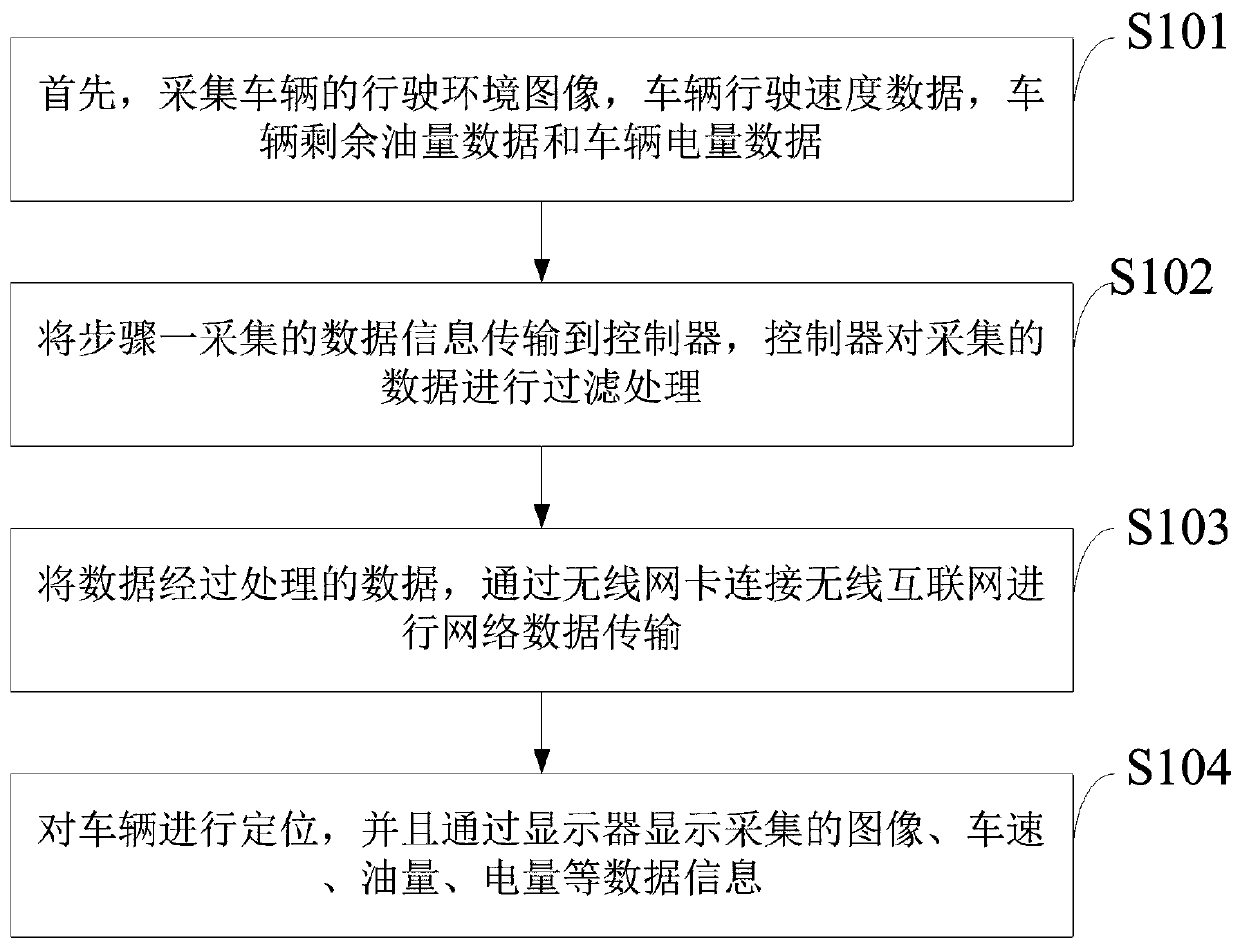

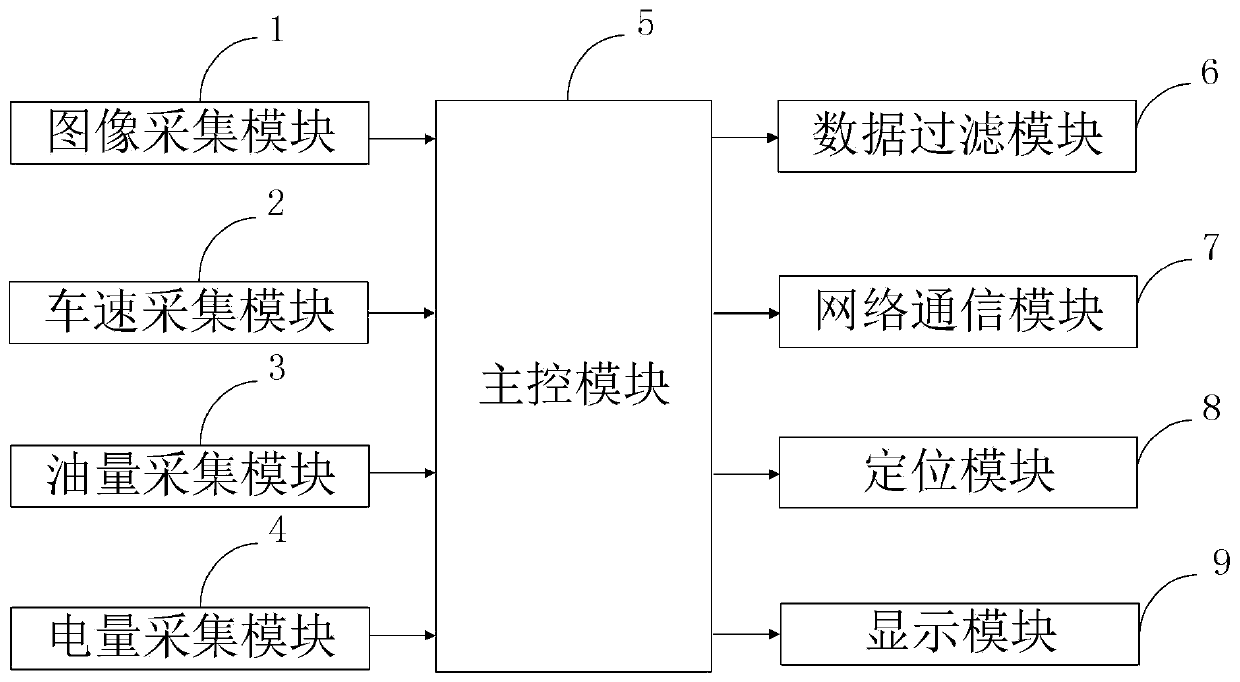

Internet-of-vehicle data transmission method and system

InactiveCN109903545AHigh precisionImprove stabilityImage enhancementTransmission systemsThe InternetComputer module

The invention belongs to the technical field of an internet of vehicles and discloses an internet-of-vehicle data transmission method and system. The internet-of-vehicle data transmission system comprises an image acquisition module, a vehicle speed acquisition module, an oil volume acquisition module, a power acquisition module, a main control module, a data filtering module, a network communication module, a positioning module and a display module. The travel data is filtered and modified through the data filtering module, thereby further improving the accuracy and stability of an algorithmand greatly improving the accuracy of the vehicle data; and meanwhile, through the positioning module, the track of a vehicle to be positioned is matched with the road, then, position deviation obtained through matching is utilized to correct location of nearby vehicles, path matching of the corrected nearby vehicle tracks is carried out again, and the obtained position deviation is utilized to correct the track of the vehicle to be positioned, thereby improving precision of the track of the vehicle to be positioned and improving positioning precision of the vehicle to be positioned on an electronic map. The method can be used for vehicle positioning of the electronic map.

Owner:HUBEI UNIVERSITY OF MEDICINE

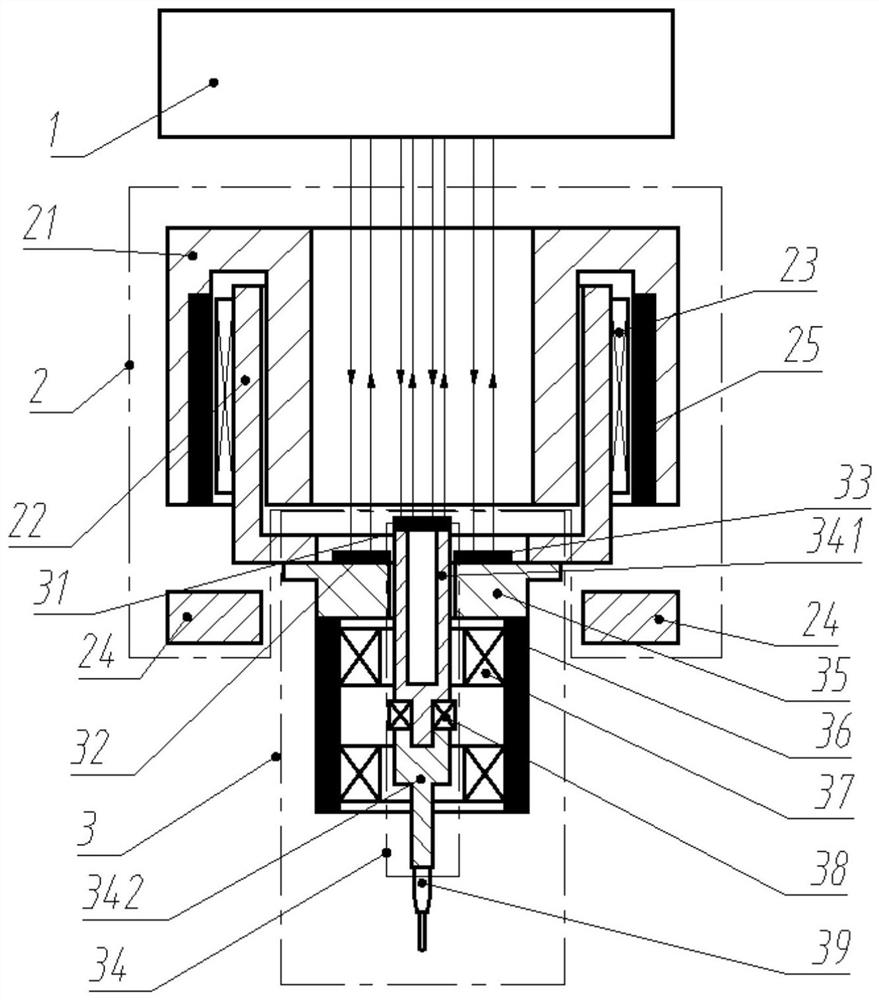

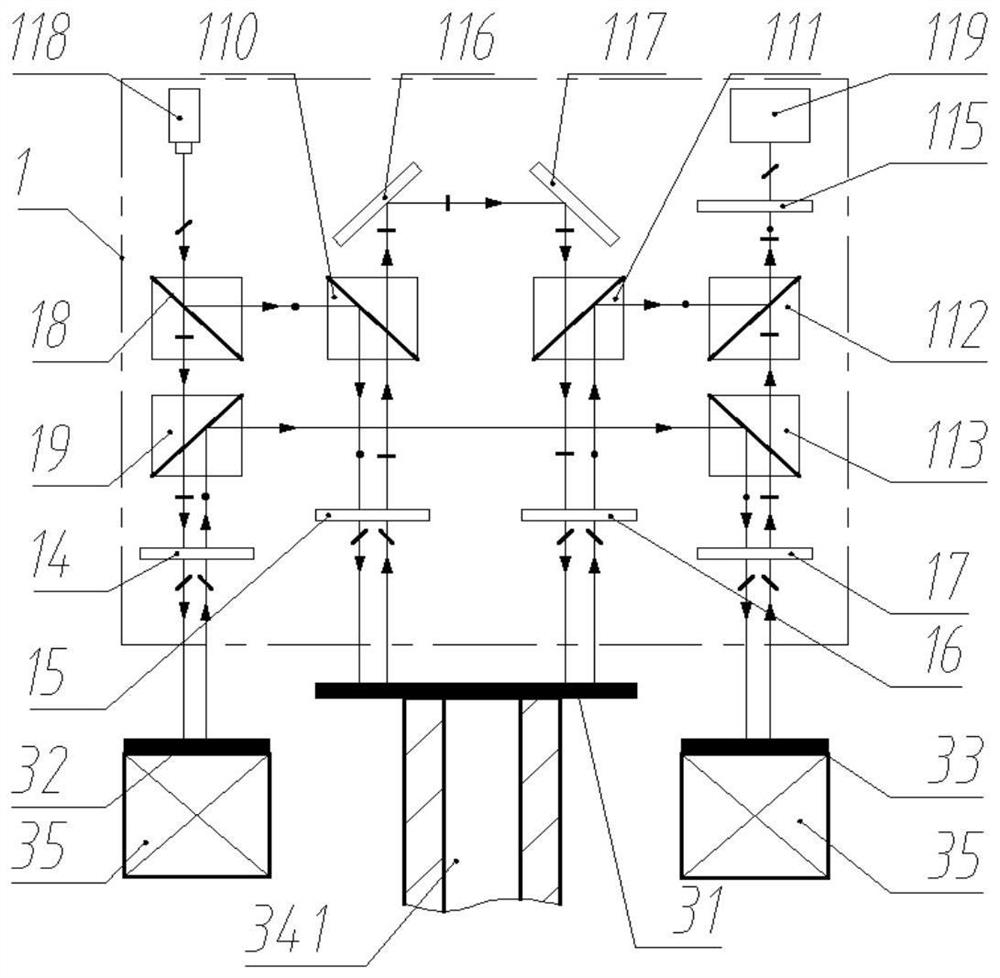

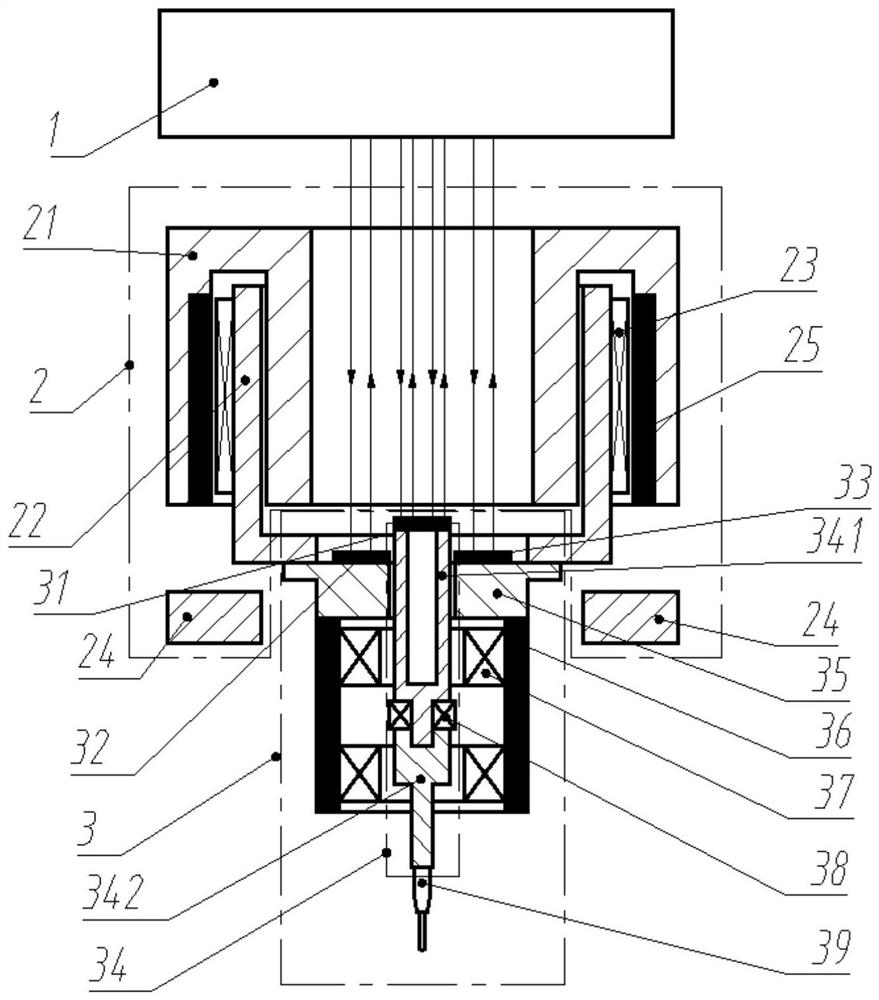

A suspension stylus displacement sensor and detection method based on differential polarization interference

ActiveCN112525080BAvoid nonlinear errorsHigh measurement accuracyUsing optical meansElectric machineryEngineering

The invention belongs to the technical field of precision displacement measurement, and discloses a displacement sensor and detection method of a suspension stylus based on differential polarization interference. The needle mechanism and the suspension stylus mechanism are connected to the voice coil motor; the voice coil motor includes a movably connected voice coil motor stator and a voice coil motor mover, and the voice coil motor mover is used to drive the suspension stylus mechanism to move vertically; The suspension stylus mechanism includes a suspension bearing connected to the voice coil motor mover and a stylus shaft movably connected to the suspension bearing; the differential polarization interferometer is used to measure the displacement of the stylus shaft relative to the suspension bearing to obtain the primary displacement; through Measure the displacement of the voice coil motor mover relative to the voice coil motor stator to obtain the secondary displacement, and combine the primary displacement and secondary displacement to obtain the measurement result of the surface to be measured. The invention improves the stability and reliability, and expands the measurement range.

Owner:HUAZHONG UNIV OF SCI & TECH

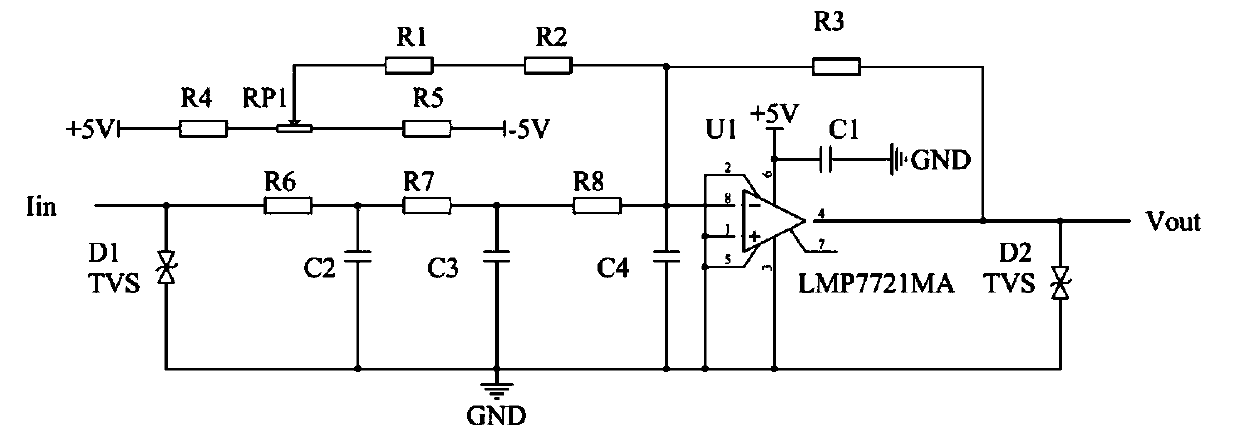

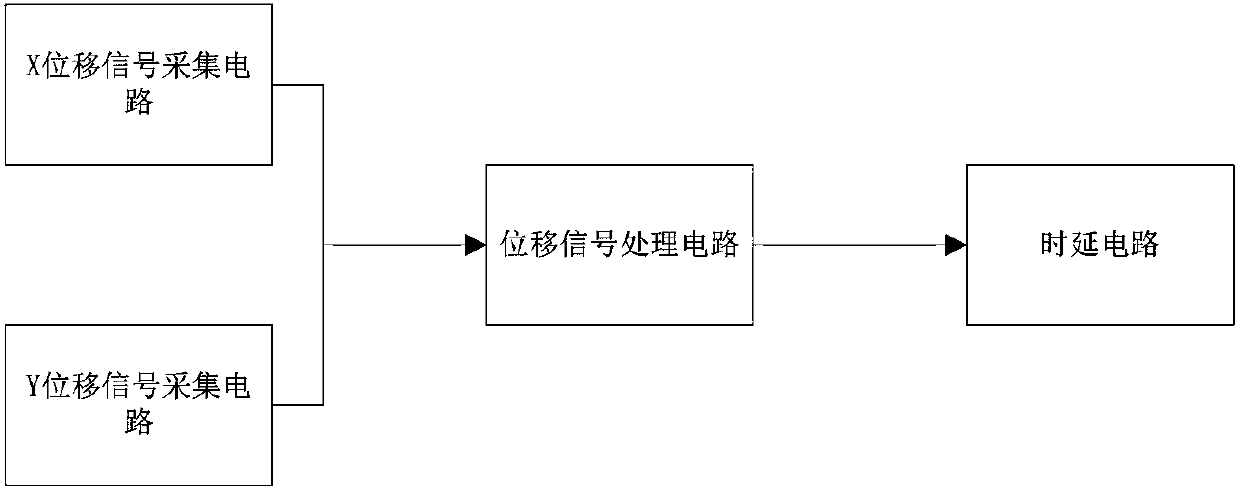

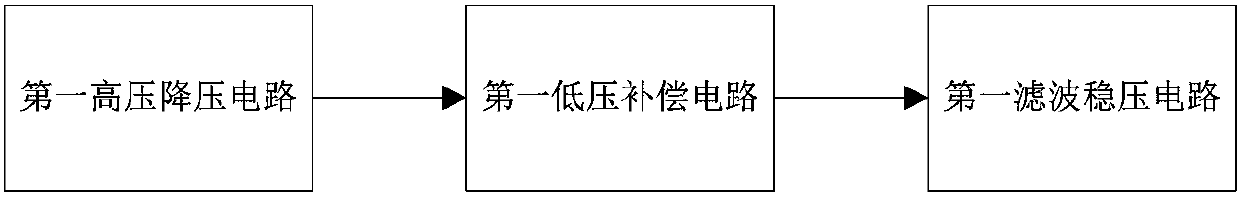

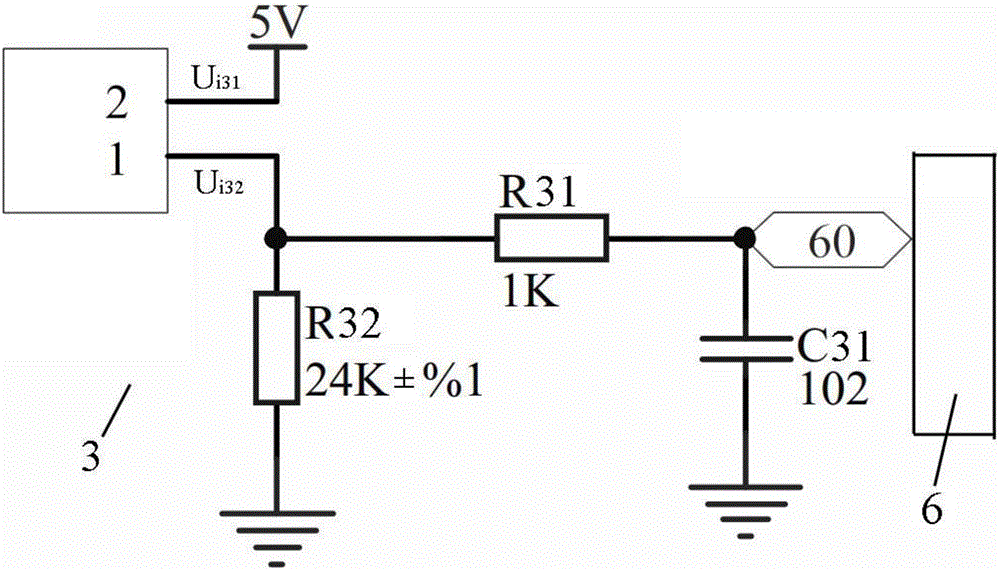

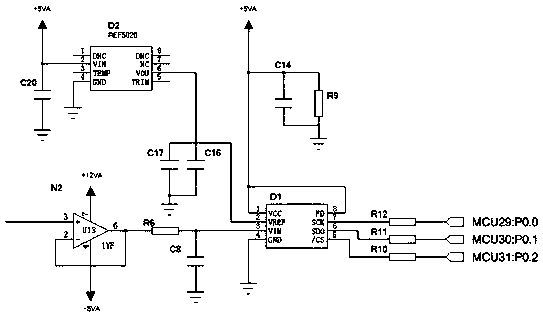

Roller deflection signal processing device for pvc calender

The invention discloses a PVC (polyvinyl chloride) calender roller deflection signal processing device which comprises an X displacement signal acquisition circuit, a Y displacement signal acquisition circuit, a displacement signal processing circuit and a time delay circuit. Transverse and longitudinal displacement signals of PVC calender rollers can be acquired by laser sensors X1 and Y1 in the X displacement signal acquisition circuit and the Y displacement signal acquisition circuit, amplitude can be adjusted by a high-voltage step-down circuit and a low-voltage compensation circuit, then the transverse and longitudinal displacement signals can be filtered by an LC circuit, and voltages of the transverse and longitudinal displacement signals can be stabilized by a voltage stabilizer tube to be in the ranges of +5 V and +10 V. The PVC calender roller deflection signal processing device has the advantages that the shortcoming of nonlinear errors due to external disturbance can be overcome, the measurement accuracy can be improved, reliable on or off of MOS (metal oxide semiconductor) tubes T1-T4 can be guaranteed by the amplitude, and the accuracy of control signals can be improved; only simple logic judgment is carried out on the availability of transverse and longitudinal displacement deviation signals by a NAND gate circuit with the MOS tubes T1-T4 in the displacement signal processing circuit, the time is delayed by 5 S, determined high or low level can be outputted to a controller, accordingly, the PVC calender roller deflection signal processing device is fast in response and high in efficiency, deflection can be timely discovered and controlled, calendering effects can be guaranteed, and the work efficiency can be improved.

Owner:PUYANG TAIPU ADHESIVE PROD

A Neural Network Based Output Control Method for Piezoelectric Ceramic Actuators

ActiveCN110108443BEasy to trainAvoid nonlinear errorsAerodynamic testingDesign optimisation/simulationLinear controlSimulation

Owner:DALIAN UNIV OF TECH

Main board for thermometer and thermocouple precision correcting method

InactiveCN101846558BRealize extensibilityReduce distractionsThermometers using electric/magnetic elementsUsing electrical meansHemt circuitsLinearity error

The invention relates to a main board for a thermometer and a thermocouple precision correcting method; the main board comprises a main control circuit consisting of a microprocessor, a dial-up input circuit, an interface circuit with at least two slots and a thermocouple sampling circuit; the invention controls the line structure of the sampling circuit with an A / D conversion circuit, reduces the line interference between digital and analog circuits, adds a zero calibration compensation circuit on the front end of the A / D conversion circuit and improves the accuracy of temperature measurement; the invention has the benefits that a bus-type interface circuit is adopted, and a plurality of interface circuit sockets are arranged to realize the extendibility of functions; the A / D conversion circuit is connected with the control end of the analog circuit, thereby reducing the connecting lines between the digital and the analog circuits, reducing the interference of the analog circuit to the digital circuit, and improving the work reliability; and the invention adds the zero calibration compensation circuit, so that when a zero point tends to be negative, the adjustment is very convenient, thereby preventing nonlinear zero-crossing error, and improving the accuracy of temperature measurement.

Owner:北京市科海龙华工业自动化仪器有限公司

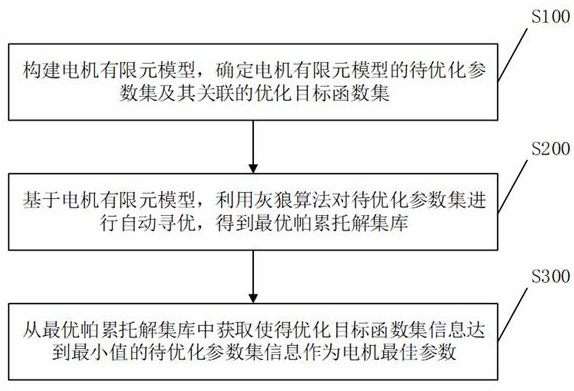

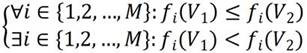

Motor parameter design method and system based on grey wolf algorithm

InactiveCN114757112AAvoid nonlinear errorsImprove search efficiencyDesign optimisation/simulationMulti-objective optimisationElement modelAlgorithm

The invention discloses a motor parameter design method and system based on a grey wolf algorithm, which are mainly applied to the technical field of motor optimization, and the method comprises the following steps: step 100, constructing a motor finite element model, and determining a to-be-optimized parameter set of the motor finite element model and an associated optimization objective function set; step 200, based on the motor finite element model, performing automatic optimization on the to-be-optimized parameter set by using a grey wolf algorithm to obtain an optimal Pareto solution set library; and step 300, obtaining the to-be-optimized parameter set information which enables the optimization objective function set information to reach the minimum value from the optimal Pareto solution set library as the optimal parameter of the motor. According to the method, the motor finite element model, the grey wolf algorithm and the Pareto dominating relation are introduced for iterative calculation, the optimization efficiency of the optimal parameters of the motor can be effectively improved, and the number of iterations is reduced.

Owner:佛山仙湖实验室

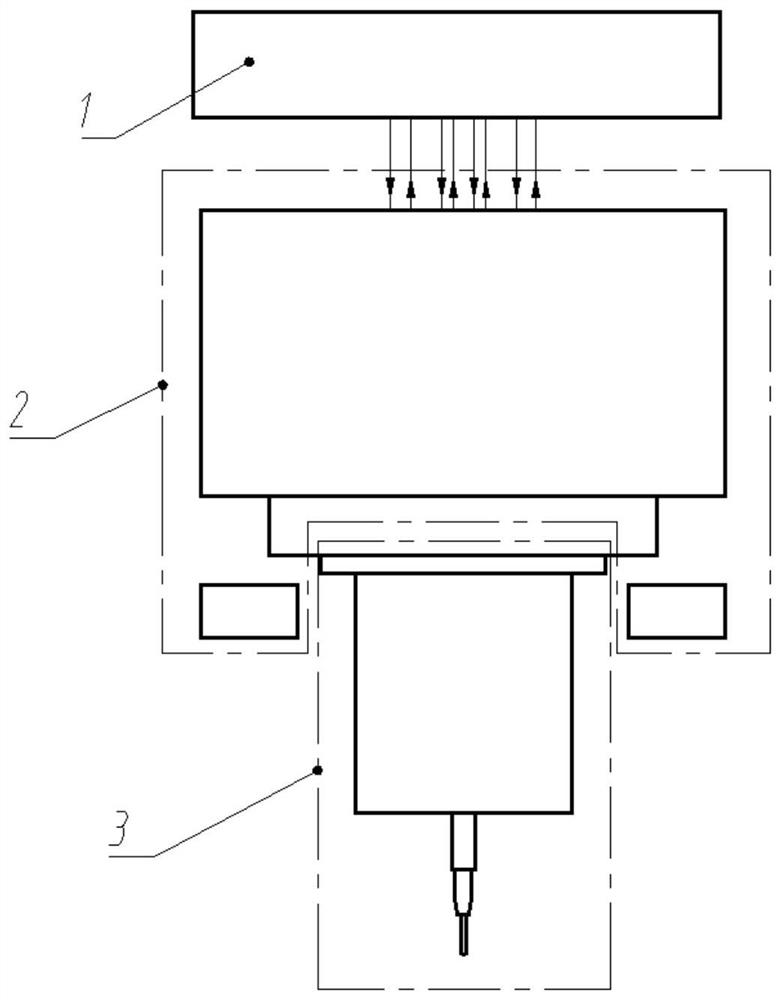

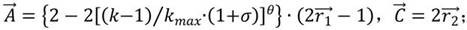

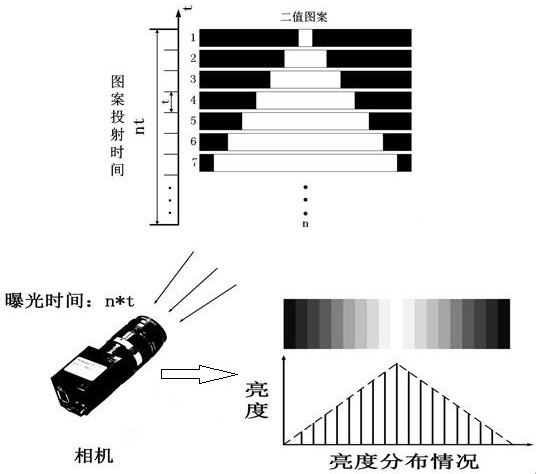

Fast grayscale fringe synthesis method based on focused binary pattern

ActiveCN109029294BProjection time reducedAvoid nonlinear errorsUsing optical meansTriangular diagramGraphics

The invention discloses a rapid gray stripe synthesis method based on a focusing binary pattern. The method comprises the steps of coding a binary pattern group comprising multiple binary patterns, wherein the widths of white areas of the binary patterns are sequentially increased with equal distance, and thus a ladder-shaped triangular pattern; sequentially projecting the binary pattern group toan object under test by using a projection instrument; and collecting projection patterns of the binary pattern group by using a camera, adjusting exposure time of the camera, thus completing collection of the projection patterns of the binary pattern group within one exposure time slot of the camera, and combining the projection patterns into a gray-intensity triangular wave stripe pattern. According to the method provided by the invention, the projection time of the gray pattern synthesized by the binary patterns is great reduced, so that the non-linear error of the stripe generated by a projector is avoided. The triangular wave stripe pattern synthesized by the invention is simple in waveform, easy to accurately synthesize, and beneficial to phase resolving and three-dimensional reconstruction.

Owner:HEFEI UNIV OF TECH

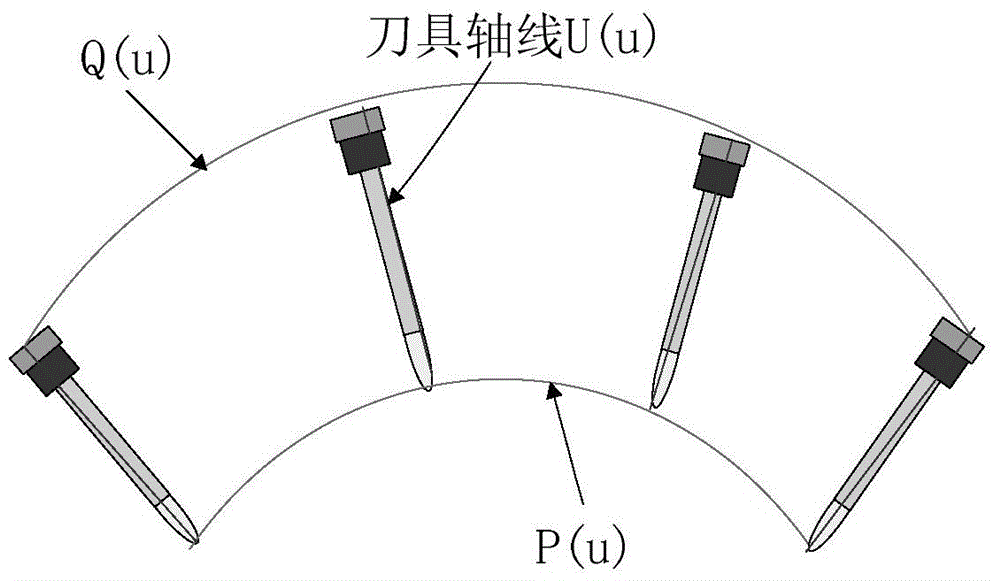

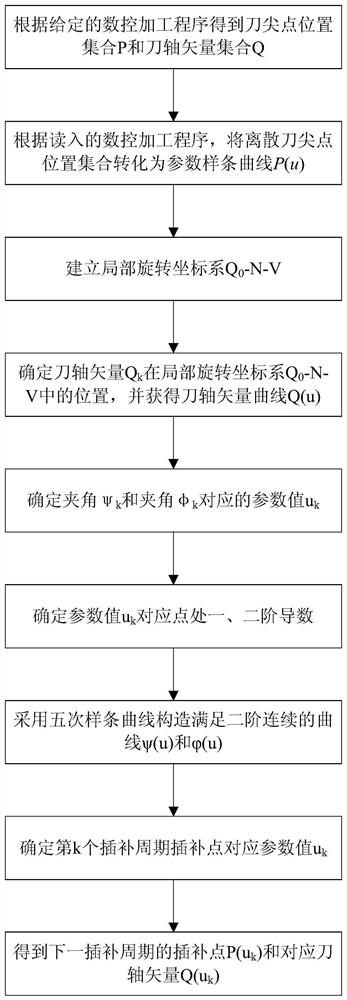

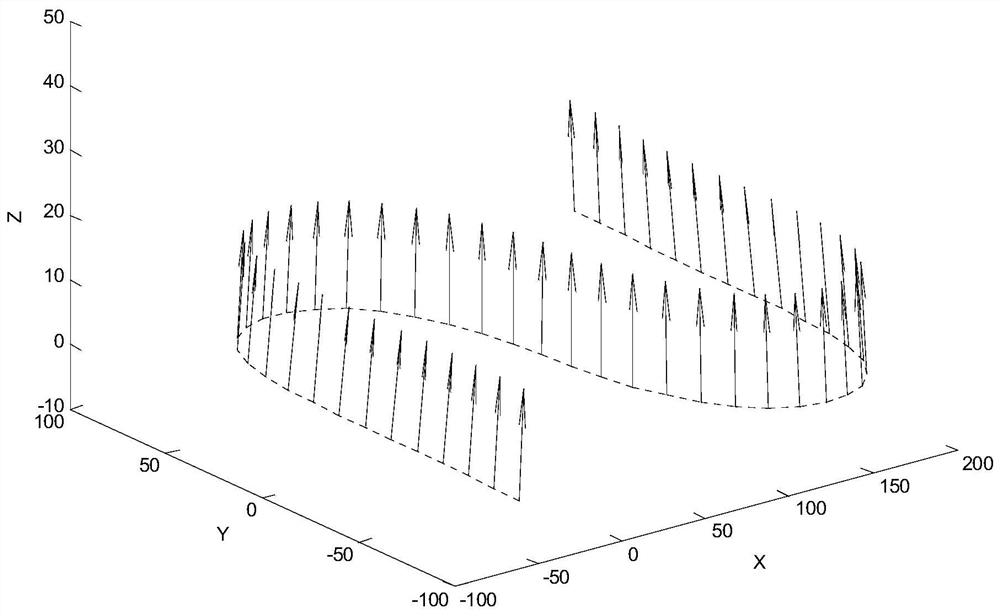

A five-axis CNC machining instruction point interpolation method based on tool attitude control

ActiveCN109032077BGuaranteed continuityAvoid nonlinear errorsProgramme controlComputer controlNumerical controlRotational axis

The invention provides a five-axis numerical control machining instruction point interpolation method based on tool attitude control, and relates to the field of numerical control machining. Including: obtaining tool tip position set P and tool axis vector set Q; obtaining parameter spline curve P(u); establishing local rotating coordinate system Q 0 ‑N‑V; get the tool axis vector curve Q(u); determine the included angle ψ k The parameter value u corresponding to the included angle k ; Determine parameter value u k The first and second order derivatives at the corresponding points; construct the curve ψ(u) that satisfies the second order continuity and determine the corresponding parameter values of the kth interpolation cycle interpolation point; obtain the interpolation point and the corresponding tool axis vector of the next interpolation cycle . The present invention provides a five-axis numerical control machining command point interpolation method based on tool attitude control, which avoids the nonlinear error caused by the change of the rotation axis in the linear interpolation method, improves the machining accuracy, and avoids the distortion of the rotation axis of the machine tool. Great changes to improve the smoothness of the machined surface.

Owner:SHENYANG JIANZHU UNIVERSITY

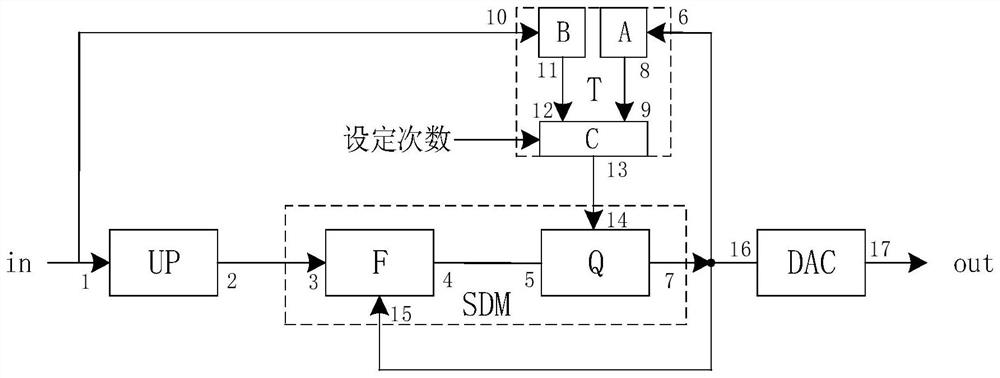

Single-bit sigma delta DAC circuit

PendingCN114640353ALow costReduce the difficulty of implementationAnalogue conversionLevel shiftingSoftware engineering

The invention discloses a single-bit sigma delta DAC (Digital to Analog Converter) circuit. The high-order single-bit sigma delta modulator comprises an up-sampling filter, a high-order single-bit sigma delta modulator, a 1-bit DAC (Digital-to-Analog Converter) circuit and a threshold generation module, wherein the high-order single-bit sigma delta modulator comprises a noise shaping filter and a quantizer. The threshold value generation module comprises a unit time signal high-low level conversion frequency counting device, a maximum threshold value limiting device and a threshold value adjusting device. The high-low level conversion frequency counting device counts the high-low level conversion frequency of the quantizer output signal in unit time; the maximum threshold limiting device determines a maximum threshold according to the amplitude of the input signal; and the threshold value adjusting device receives the high-low level conversion times and the maximum threshold value of the output signal of the quantizer, and inputs the current threshold value into the quantizer in combination with the built-in set times. According to the invention, the circuit cost is saved, the introduced nonlinear error is avoided, and the cost and implementation difficulty of the 1-bit DAC are reduced.

Owner:HANGZHOU NATCHIP SCI & TECH

Method and device for measuring frequency response of photodetector based on dual-tone modulation

ActiveCN113341222BReduce frequency requirementsHigh resolutionSpectral/fourier analysisTesting optical propertiesPhase responsePhotodetector

The invention discloses a method for measuring the frequency response of a photoelectric detector based on dual-tone modulation. Two channels with different frequencies ω 1 , ω 2 The microwave signal is modulated on the same optical carrier to generate an optical double-sideband signal of suppressed carrier; use the photodetector to be tested to convert the optical double-band signal of suppressed carrier into an electrical signal, and extract the up-converted and down-converted frequency Signal components, and calculate the amplitude-phase response of the photodetector to be tested accordingly. The invention also discloses a photodetector frequency response measuring device based on dual-tone modulation. Compared with the prior art, the invention can effectively reduce the measurement error introduced in the measurement process, improve the measurement accuracy and improve the dynamic range.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

PGC-DCDM Demodulation Method Insensitive to Phase Delay and Modulation Depth

ActiveCN110411486BSolve the unmeasurableAvoid nonlinear errorsConverting sensor output opticallyComputational physicsPhase modulation

Owner:ZHEJIANG SCI-TECH UNIV

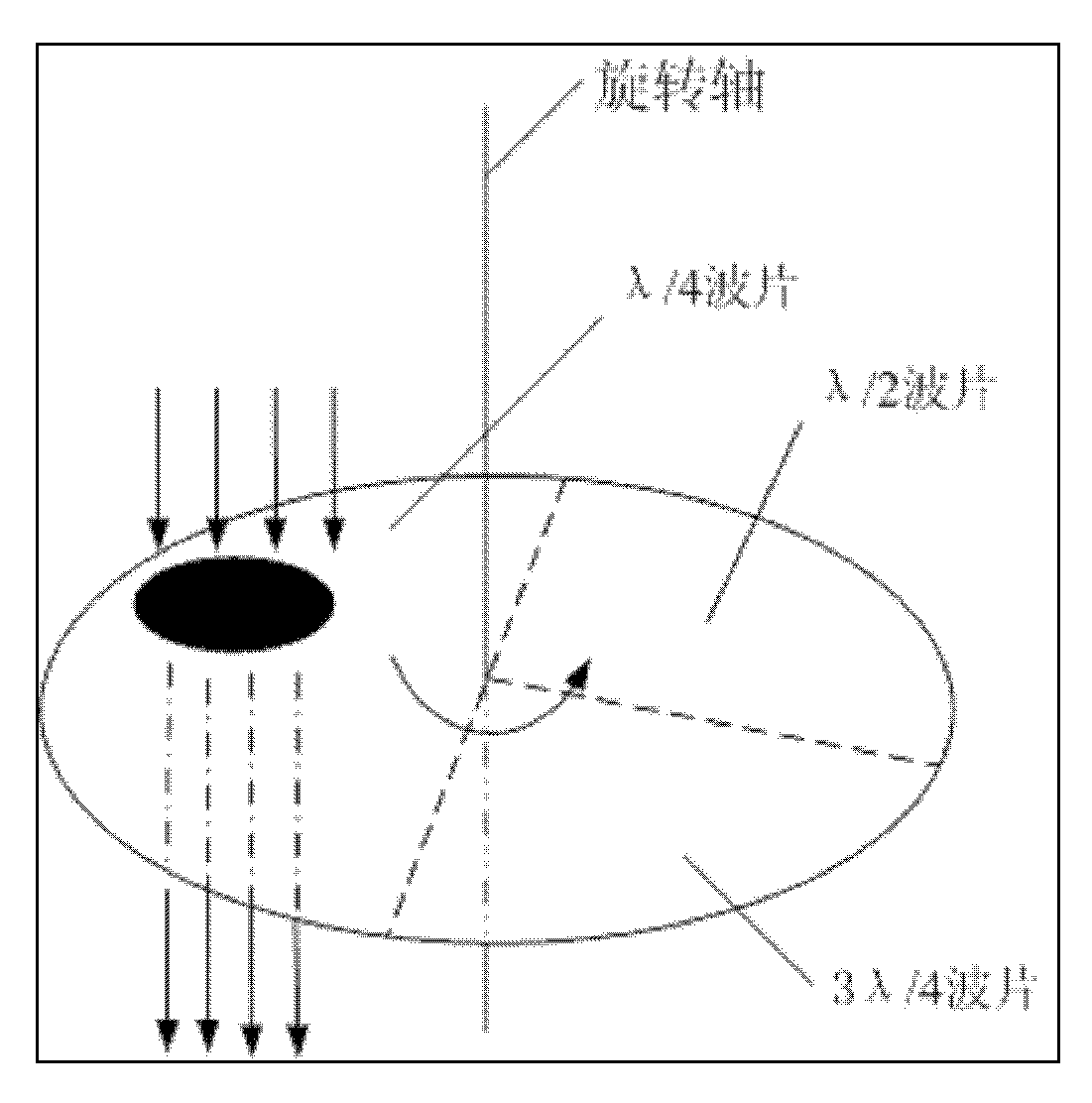

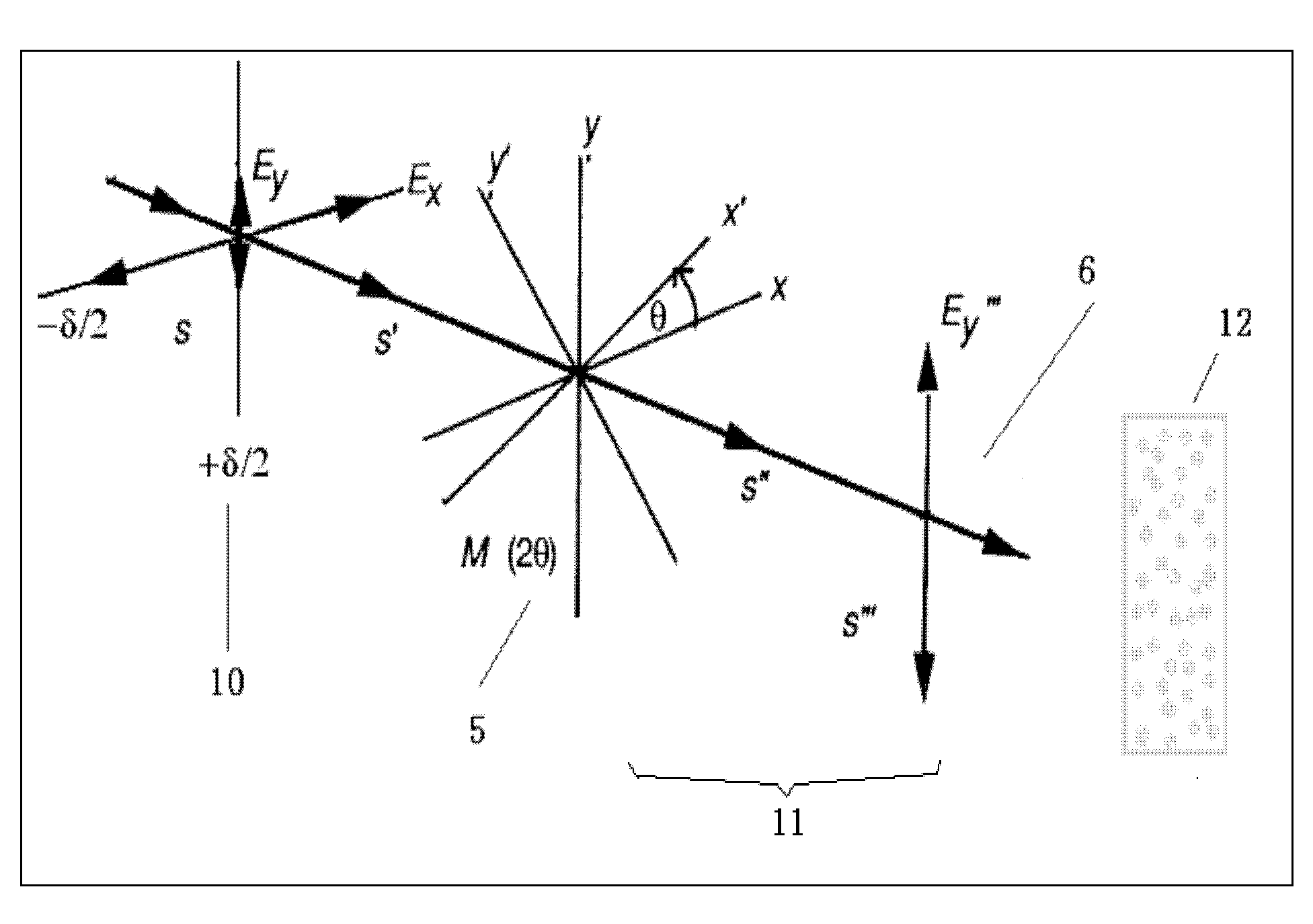

Polarization and birefringence measuring system

ActiveCN102621072BSuppress noiseSource of average errorMaterial analysis by optical meansLuminous intensityPhase difference

The invention provides a polarization and birefringence measuring system in which measuring accuracy of polarization and stress birefringence is increased by using a multi-wave plate combination. The measuring system comprises a light source module, a light signal modulation module and a data collecting and processing module, wherein the light source module comprises a light source, a collimation and expansion system and a polarizer; the light signal modulation module comprises a multilevel phase difference coaxial wave plate, an analyzer, a stepping motor driving device and a stepping motor; and the data collecting and processing module comprises an image capture card, an luminous intensity detector and a computer. According to the polarization and birefringence measuring system, influences of changes of environments and measurement conditions such as air movement, temperature variation and uncertain vibration modes are effectively avoided; more than one independent phase modulation element is used for suppressing noises and averaging main error sources; and three wave plates are used for measuring the polarization and the birefringence, so that non-linear errors caused by non-linear influence of the system are effectively avoided, and the measuring accuracy is greatly improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

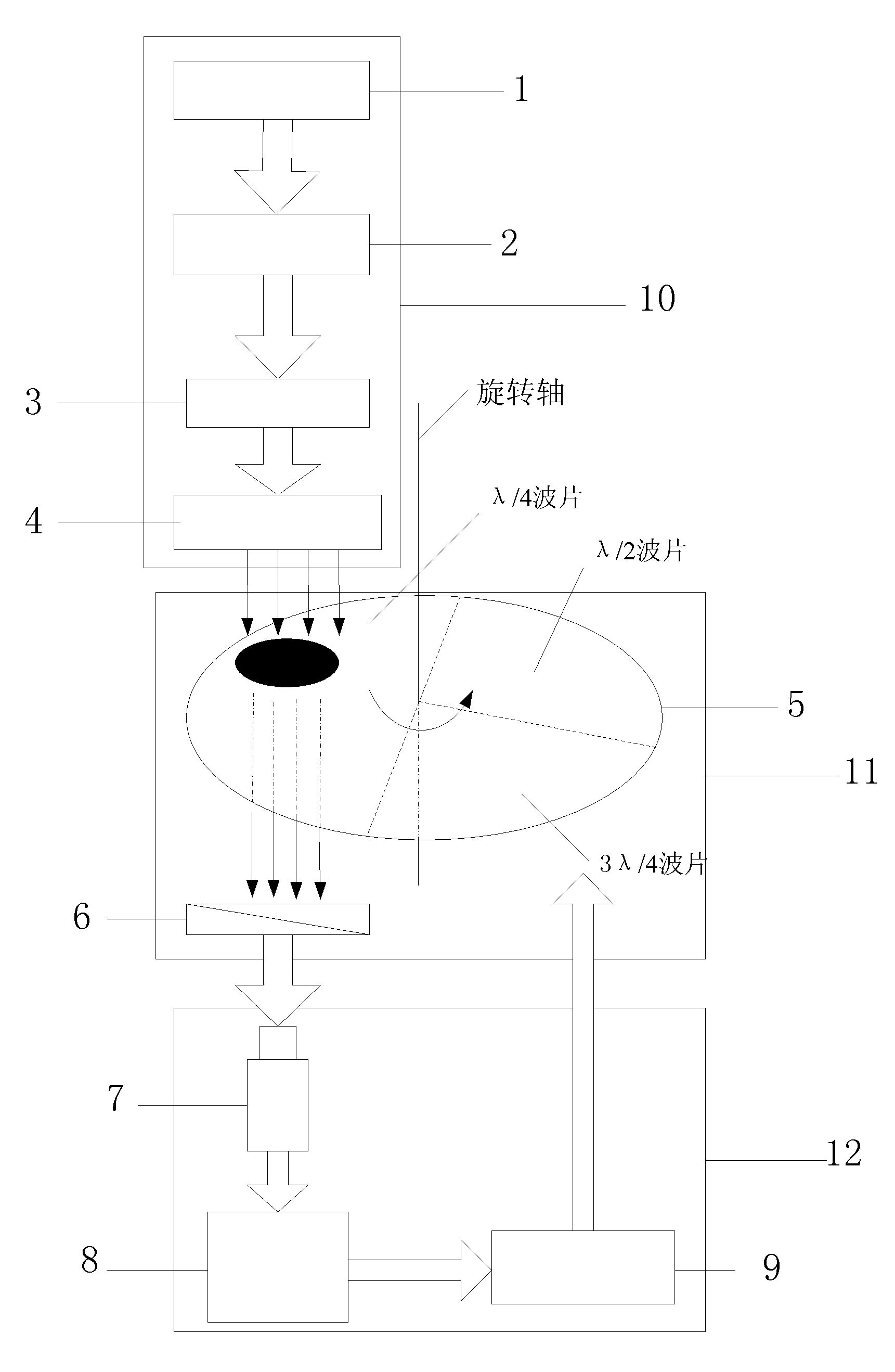

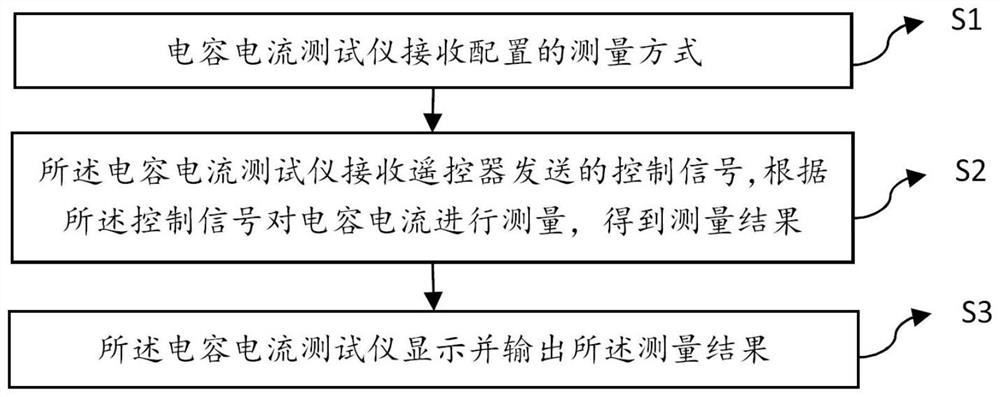

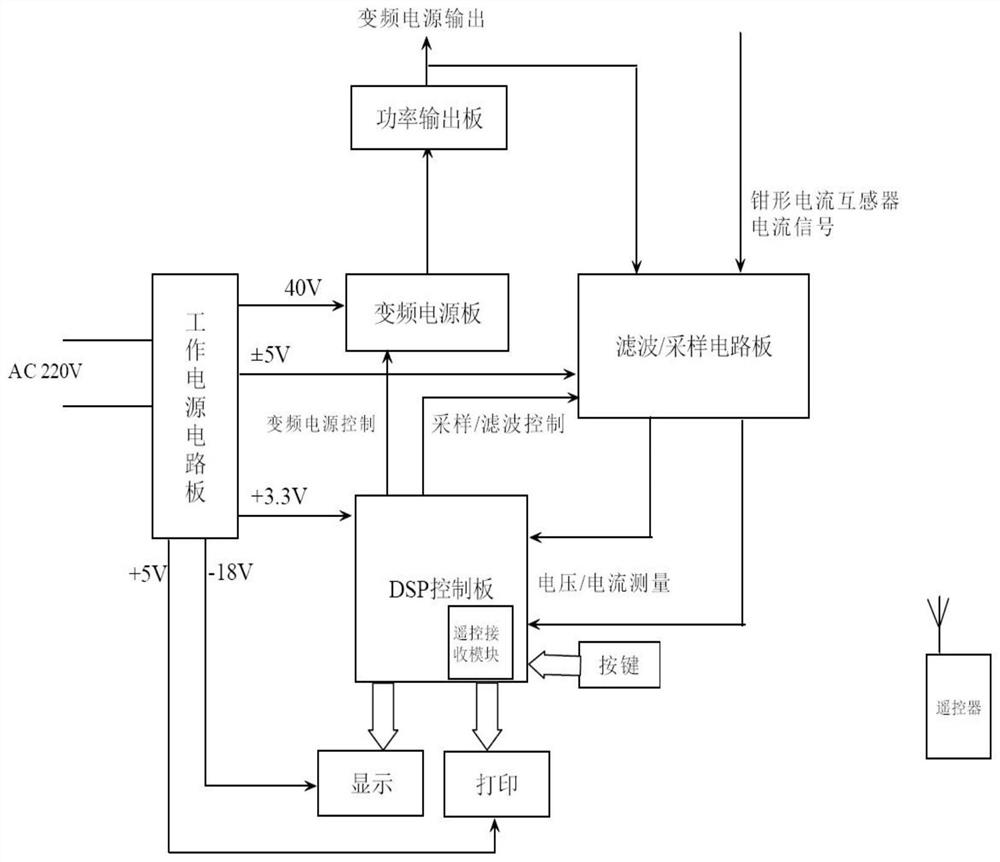

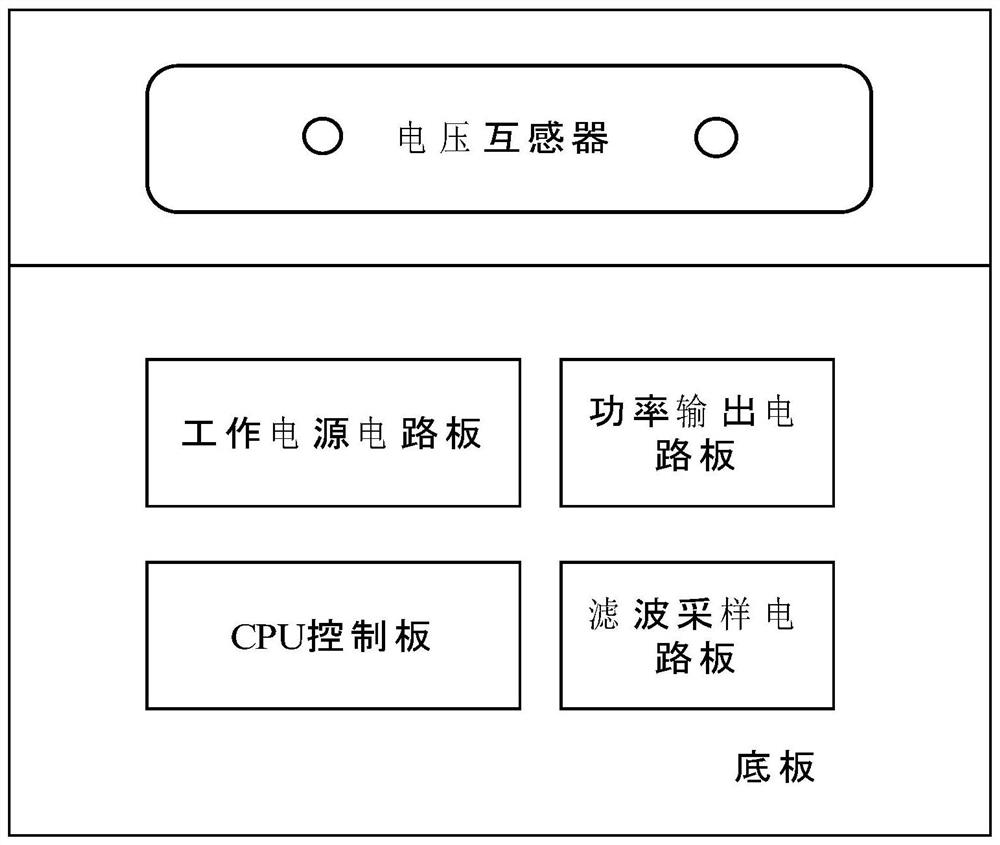

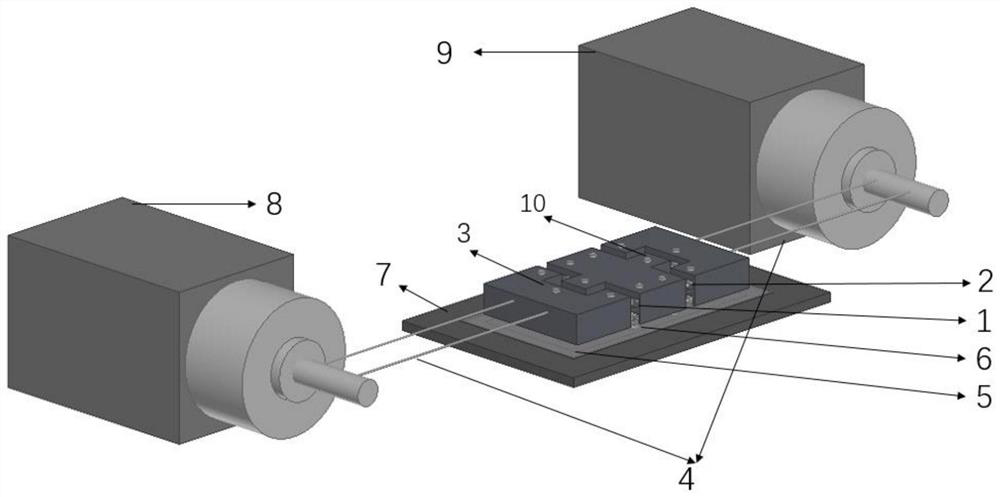

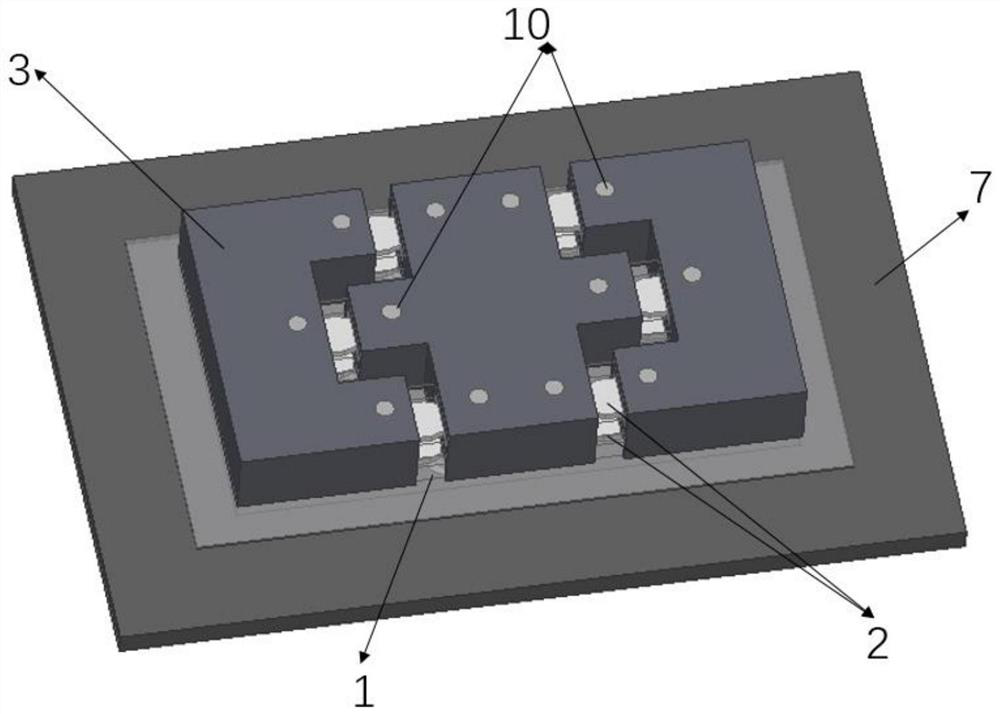

Novel power distribution network capacitance and current measurement method and system

PendingCN112540321AAvoid nonlinear errorsImprove measurement efficiencyCurrent/voltage measurementFault location by conductor typesCapacitanceTransformer

The invention relates to a novel power distribution network capacitance and current measurement method and system. The method comprises the following steps that: S1, a capacitance and current tester receives a configured measurement mode; S2, the capacitance and current tester receives a control signal sent by a remote controller, and measures the capacitance and current according to the control signal to obtain a measurement result; and S3, the capacitive current tester displays and outputs the measurement result. According to the invention, a 10 kV voltage transformer is integrated in the tester, the capacitance and the current are measured through a neutral point, and thus the nonlinear error of the measurement result caused by the use of different voltage transformers is avoided. Meanwhile, the tester has an open triangulation function and a remote control measurement function, supports flexible selection of measurement modes, and is high in measurement efficiency and low in safetyrisk.

Owner:GUANGXI POWER GRID ELECTRIC POWER RES INST

Liquid metal reconfigurable array antenna based on two-dimensional stretchable flexible cavity

ActiveCN113972480BImprove liquidityAvoid direct manipulation of controlsParticular array feeding systemsSimultaneous aerial operationsReconfigurable antennaLiquid metal

The invention belongs to the technical field of antennas, and relates to a liquid metal reconfigurable array antenna based on a two-dimensional stretchable flexible cavity and a reconfiguration method thereof. The invention utilizes the fluidity of the liquid metal to construct a frequency reconfigurable microstrip antenna, the liquid metal is filled in the sealed flexible medium cavity, the flexible medium cavity can achieve 400% stretching and elongation, and the liquid metal radiator can be changed by stretching the flexible medium cavity The size can realize the continuous adjustment of the working frequency within 5~18GHz. Compared with the reconfigurable antenna using radio frequency devices, the antenna of the present invention can realize continuous tuning in a large frequency range. The elongation of the radiator is realized by automatic stretching equipment, which is more stable and practical than the injection-type reconfigurable liquid metal antenna.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Suspension contact pin displacement sensor based on differential polarization interference and detection method

ActiveCN112525080AAvoid nonlinear errorsHigh measurement accuracyUsing optical meansElectric machineryEngineering

The invention belongs to the related technical field of precision displacement measurement, and discloses a suspension contact pin displacement sensor based on differential polarization interference and a detection method, the displacement sensor comprises a differential polarization interference device, a voice coil motor and a suspension contact pin mechanism which are arranged from top to bottom, and the suspension contact pin mechanism is connected to the voice coil motor; the voice coil motor comprises a voice coil motor stator and a voice coil motor rotor which are movably connected, andthe voice coil motor rotor is used for driving the suspension contact pin mechanism to move vertically; the suspension contact pin mechanism comprises a suspension bearing connected to the voice coilmotor rotor and a contact pin shaft movably connected to the suspension bearing; the differential polarization interference device is used for measuring the displacement of the contact pin shaft relative to the suspension bearing to obtain a first-stage displacement amount; the secondary displacement is obtained by measuring the displacement of the voice coil motor rotor relative to the voice coil motor stator, and the measurement result of the measured surface can be obtained by calculating and combining the primary displacement and the secondary displacement. According to the invention, thestability and the reliability are improved, and the measurement range is expanded.

Owner:HUAZHONG UNIV OF SCI & TECH

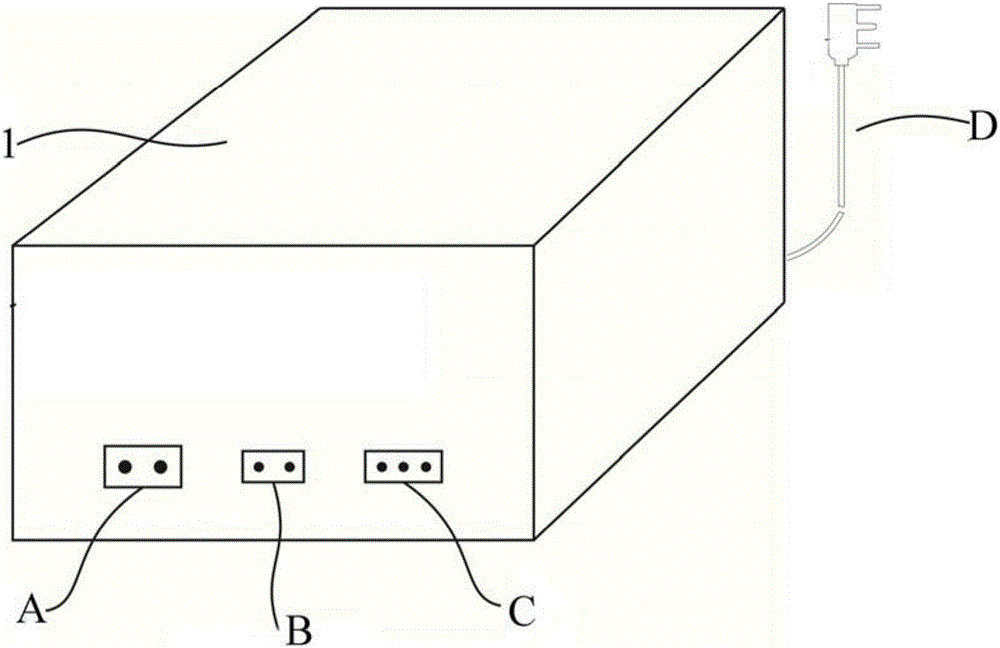

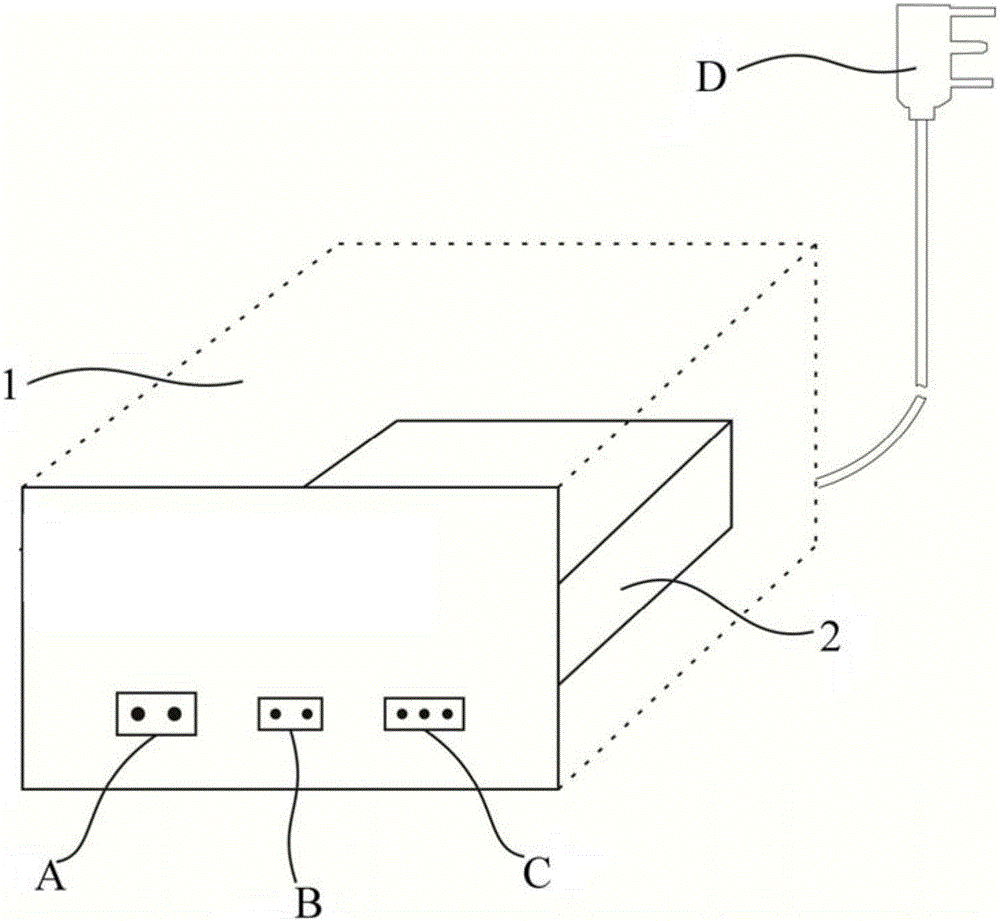

Automatic test device for heating seat rings of toilet bowls

PendingCN106771740AQuick checkQuick testResistance/reactance/impedenceElectrical testingTest efficiencyAutomatic test equipment

The invention relates to an automatic test device for heating seat rings of toilet bowls. The automatic test device comprises a resistance detection circuit, a sensor detection circuit, a processor and a power circuit. The resistance detection circuit and the sensor detection circuit are independent from each other. External tested devices can be connected into input ends of the resistance detection circuit, output ends of the resistance detection circuit are connected into the processor, external tested sensing devices can be connected into input ends of the sensor detection circuit, and an output end of the sensor detection circuit is connected into the processor; whether the tested devices are normal or not can be judged by the processor according to input signals of the resistance detection circuit and signal input states of the sensor detection circuit; power output ends of the power circuit are electrically connected with power input ends of the resistance detection circuit, the sensor detection circuit and the processor. The automatic test device has the advantages that the heating seat rings of the toilet bowls can be quickly tested by the automatic test device, the test efficiency can be improved, the test complexity can be lowered, and the automatic test device is simple in structure and convenient to operate and is portable.

Owner:RUYUAN NANLING INTELLIGENT HOUSEHOLD MACHINERY CO LTD

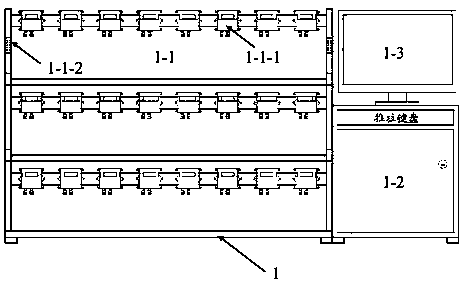

Test device of high-precision pressure transmitter aging test system

InactiveCN111238724AImplement burn-in testingGuaranteed measurement accuracyFluid pressure measurementForce/torque/work measurement apparatus calibration/testingData acquisitionModular design

The invention belongs to the technical field of pressure transmitters, and particularly relates to a high-precision pressure transmitter aging test system test device, which comprises a basic test system, and the basic test system comprises 1-10 basic test boards, a power supply / control box, a computer and a display system. Each basic test board can comprise 1-24 measurement modules, the measurement modules adopt a modular design mode, each measurement module corresponds to one pressure transmitter, two extended junction box wiring terminals are arranged at the end part of each basic test board, and the basic test boards are connected through the extended junction box wiring terminals. A data acquisition component is arranged in each measurement module, gears in an automatic range conversion circuit at the front end of the data acquisition component are divided into a 0-5mA gear and a 0-25mA gear, and the automatic range conversion circuit at the front end of the data acquisition component is controlled by a single-chip microcomputer to automatically convert the range gears. A high-power direct-current stabilized power supply is arranged in the power supply / control box, and a desktop industrial computer is adopted as the computer.

Owner:天水逢泰科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com