Five-axis numerical control machining method based on interpolation of vector of cutting tool

A processing method and cutting tool technology, which is applied in the field of five-axis linkage CNC machining, can solve the problems that cannot meet the requirements of five-axis linkage high-speed and high-precision machining, and cannot flexibly control the machining tool vector.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

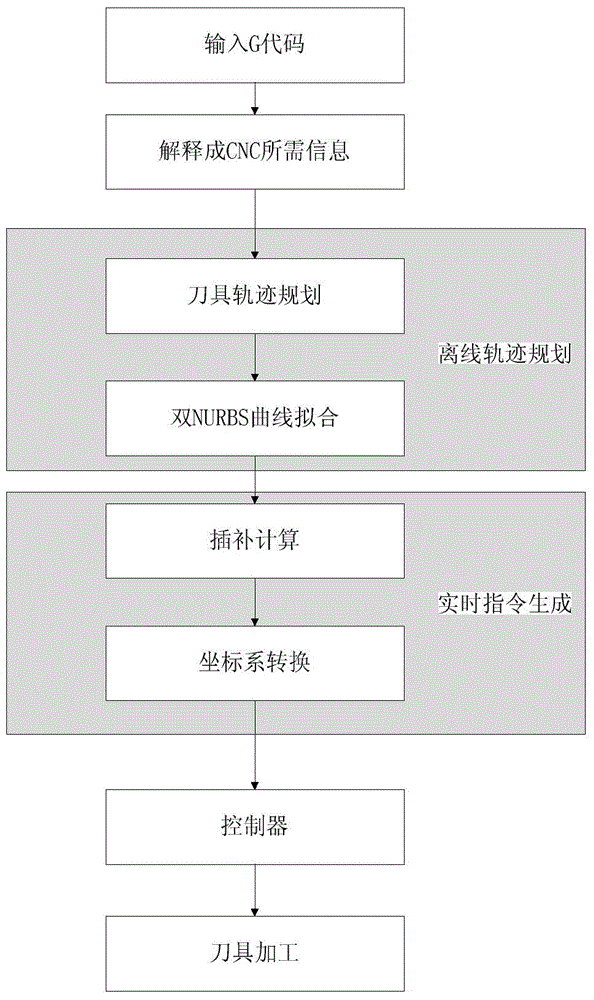

[0061] Such as figure 1 As shown, the five-axis numerical control machining algorithm based on tool vector interpolation of the present invention comprises the following steps:

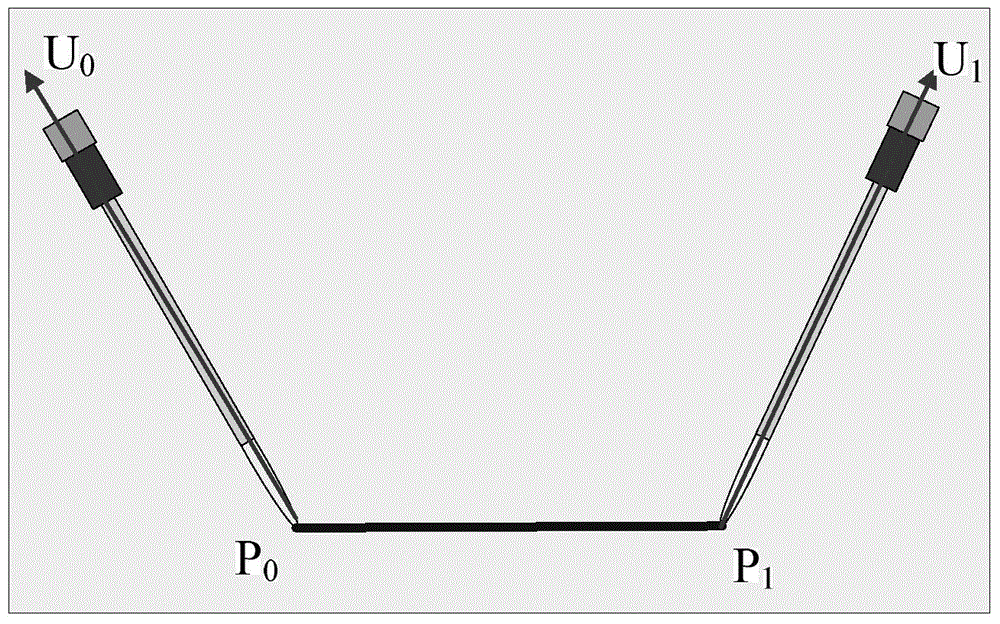

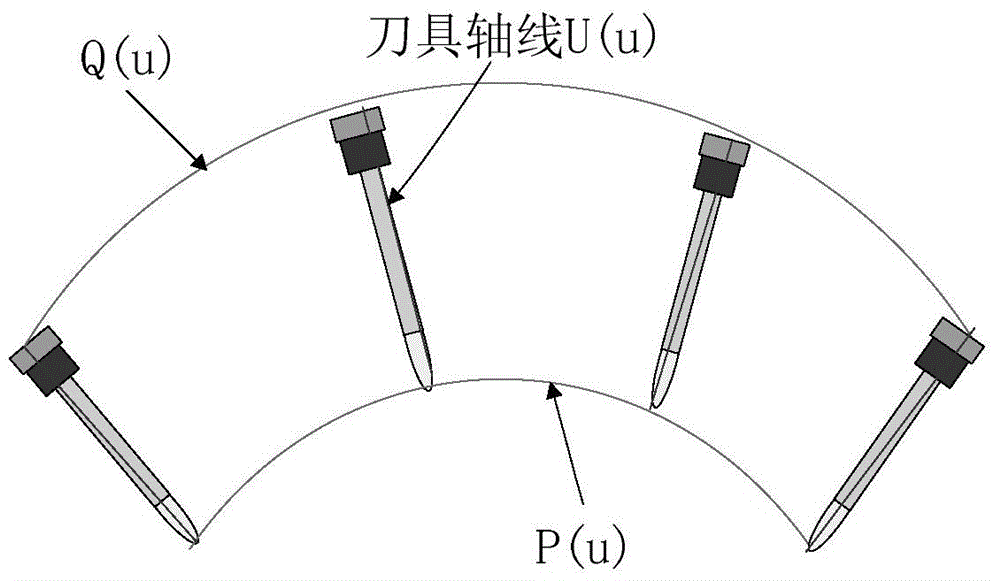

[0062] Tool trajectory planning: While realizing the tool point position planning, the tool vector interpolation calculation in the workpiece coordinate system is performed by using the plane tool vector interpolation algorithm;

[0063] Double NURBS curve fitting: use double NURBS curve fitting method to fit the curve formed by the tool tip point and the second point on the tool axis;

[0064] Interpolation calculation: Interpolate the formed NURBS curve according to the feed rate to obtain the corresponding coordinate values of each axis in the machine tool coordinate system.

[0065] Machine tool kinematics modeling and solution: for specific machine tool mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com