Main board for thermometer and thermocouple precision correcting method

A technology of thermocouples and thermometers, applied in thermometers, measuring heat, and using electrical devices, etc., can solve the problems that the interface circuit of the main board has no expansion function, measurement error affects the temperature measurement accuracy, and is unsafe, so as to achieve a simple structure , avoid nonlinear error, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

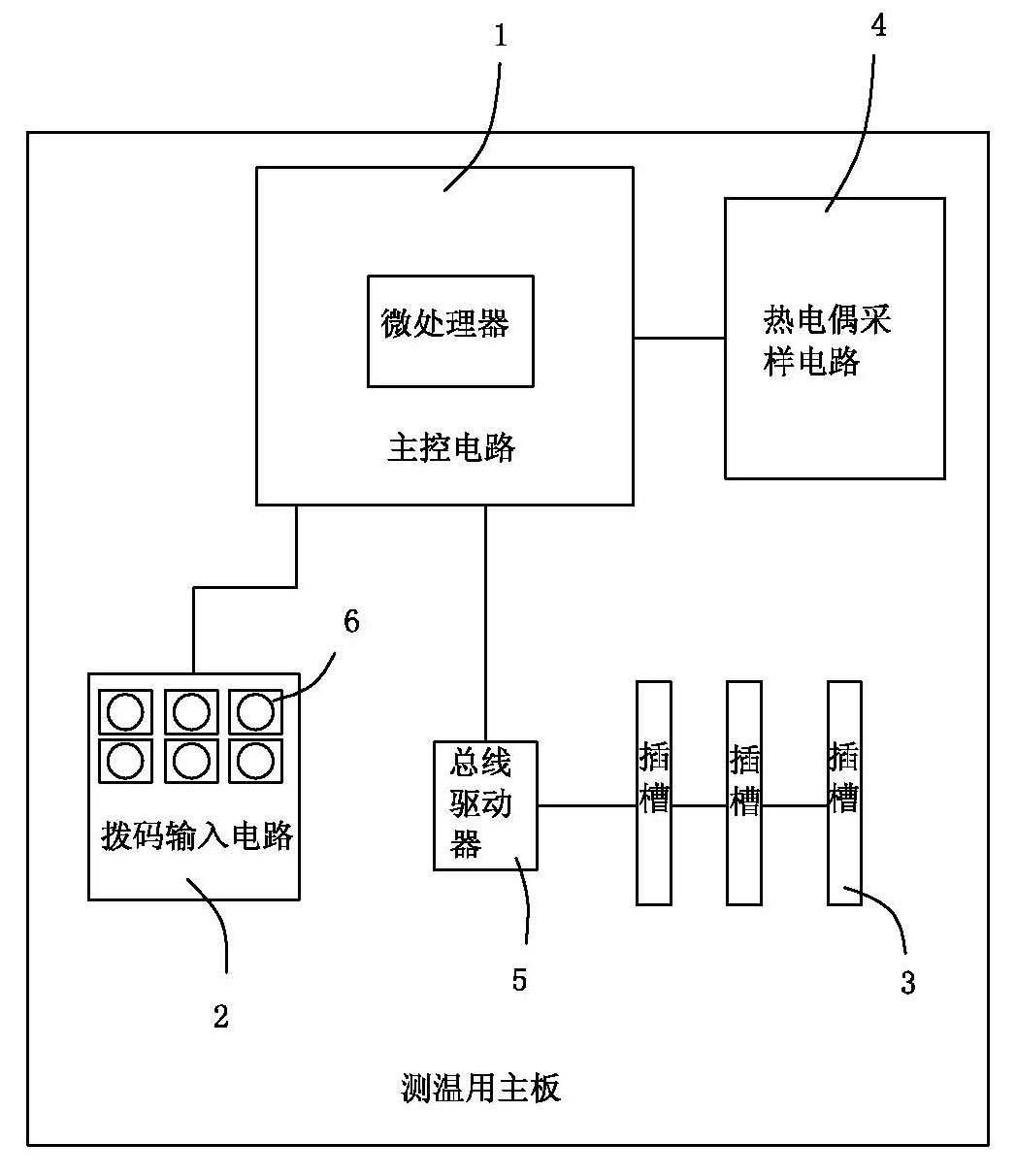

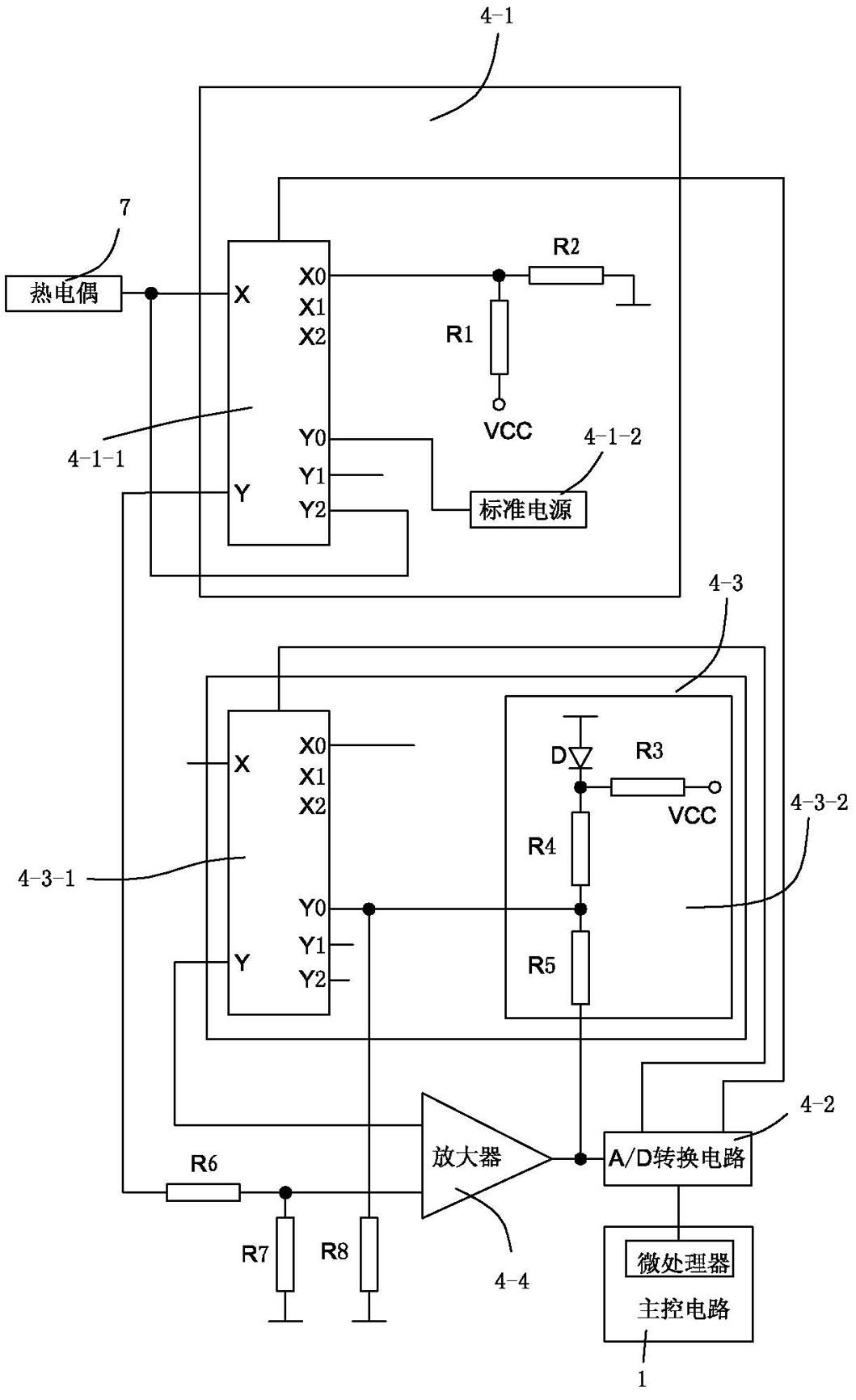

[0034] An embodiment of a motherboard for a thermometer, see figure 1 with figure 2 , the mainboard includes a main control circuit 1 containing a microprocessor and a peripheral circuit, and the peripheral circuit includes a dial input circuit 2 and an interface circuit with at least two slots 3, a thermocouple sampling circuit 4; the thermocouple The sampling circuit includes a temperature measurement control circuit 4-1, an A / D conversion circuit 4-2 and a zero compensation circuit 4-3; the slot is a 26-line double-sided straight slot, and the present embodiment is three 26-line Double sided straight slot.

[0035] The temperature measurement control circuit includes a double-way multi-position switch 4-1-1 and a standard power supply 4-1-2, wherein the standard power supply provides the standard calibration full-scale potential and zero potential of the thermocouple; the double-way multi-position switch is Two-way four-choice non-contact switch circuit, in which the sel...

Embodiment 2

[0043] An embodiment of a method for correcting the accuracy of thermocouples on the motherboard of a thermometer, see Example 1: the method includes zero point calibration and thermocouple full scale calibration, and the specific steps include:

[0044] a. Receive a zero potential, that is, the main control circuit outputs zero potential to the microprocessor by controlling the temperature measurement control circuit;

[0045] b. Judging whether it is a negative potential, if it is a negative potential, the microprocessor outputs a control signal to the A / D conversion circuit to change the reference point of the amplifier to make it a positive potential;

[0046]c. Save the measured positive bias potential to the zero point calibration register;

[0047] d. Measure a calibration thermocouple potential value;

[0048] e. Subtract the measured calibration thermocouple potential value from the data in the zero-point correction register to obtain the full-scale value of the ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com