Equipment residual service life prediction method under the condition of uncertain degradation measured data

A technology for measuring data and life prediction, which can be used in electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as predicting the remaining life of uncertain equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

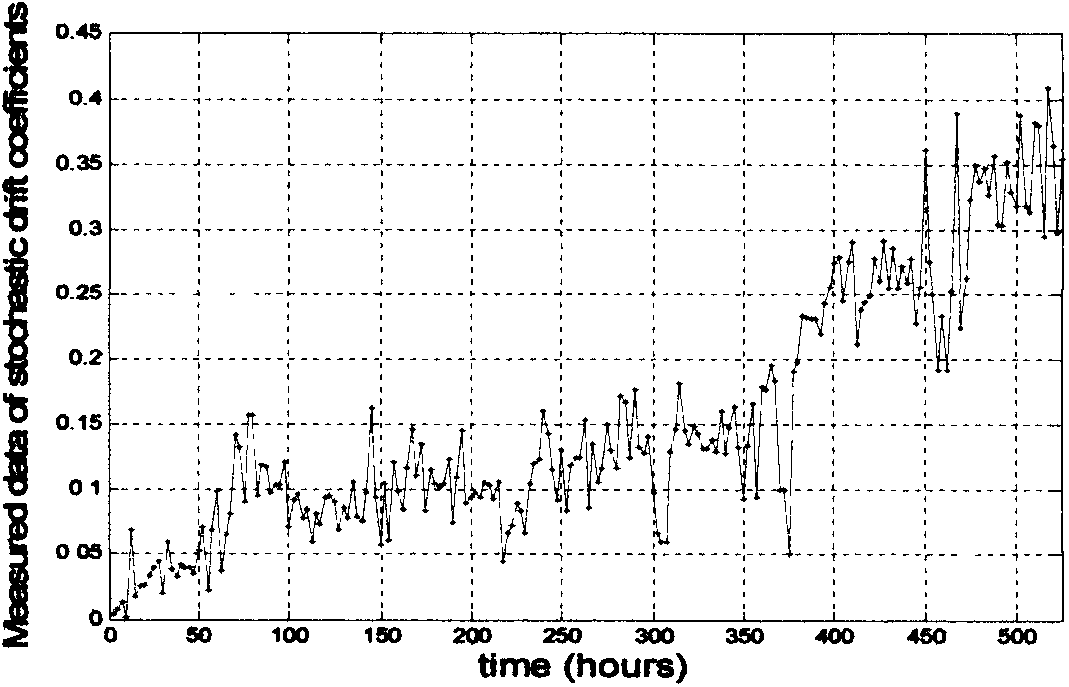

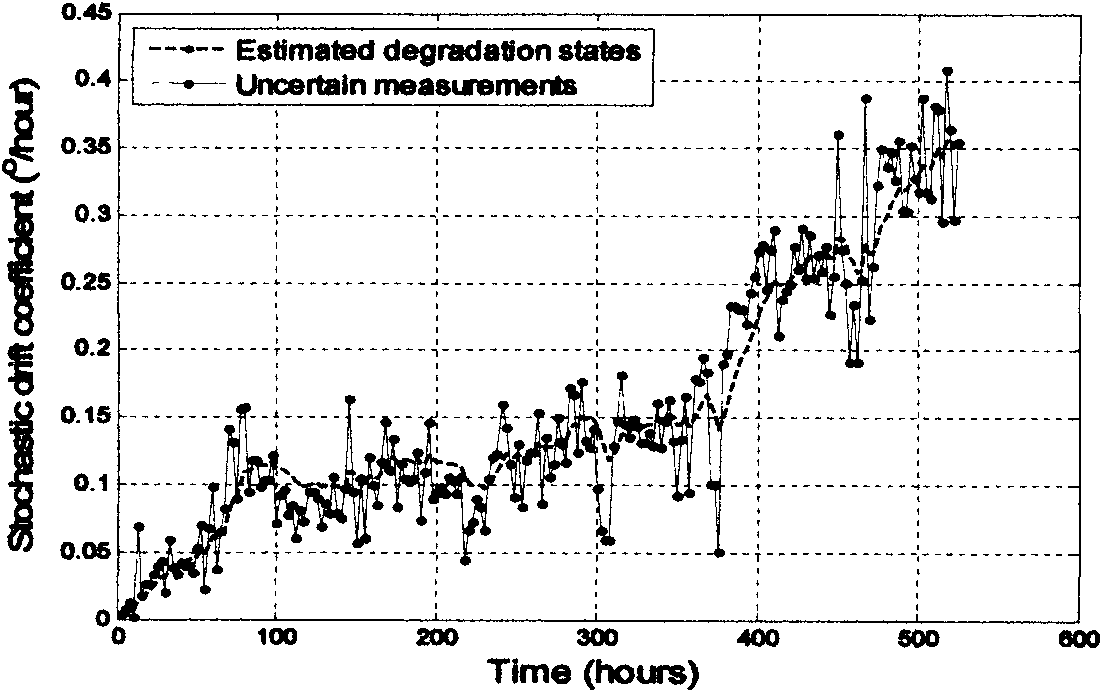

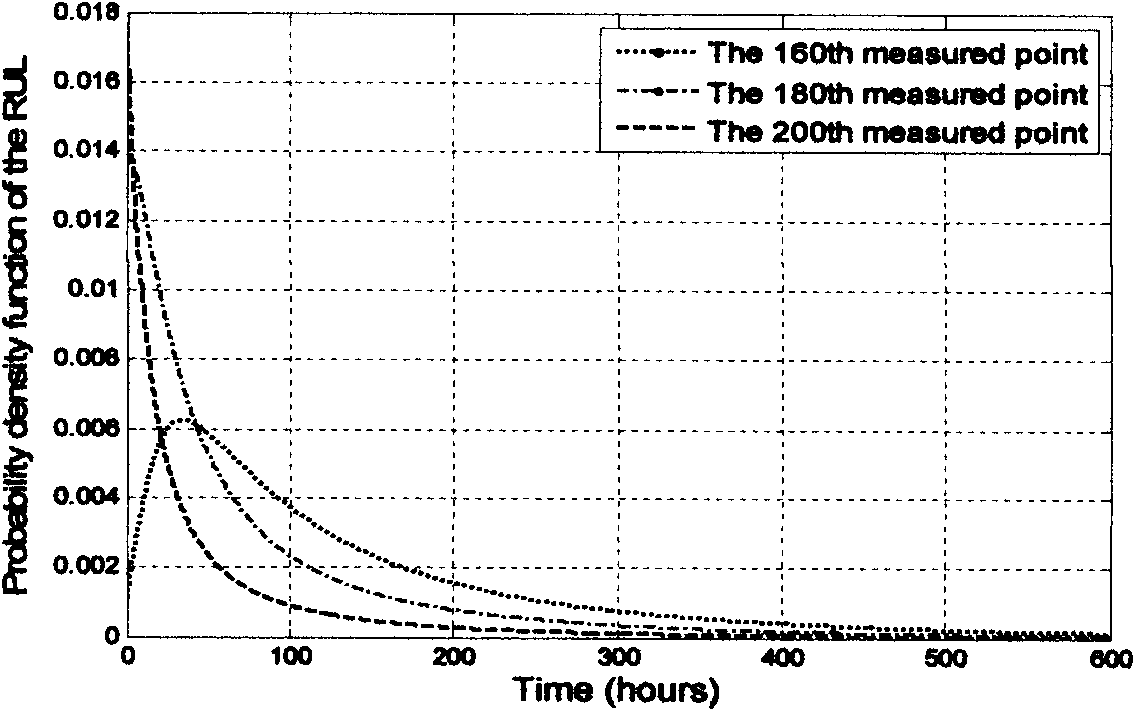

[0064] Next, a set of gyroscope drift monitoring data is obtained through the test of this embodiment to verify the method proposed by the invention. The data includes the drift coefficient data at 210 different state monitoring time points recorded by the three gyroscopes during actual use. In the experiment, according to the technical index of the gyroscope, the failure threshold is selected as w=0.36(° / hour). According to the power-on time, the monitoring interval is 2.5 hours. In the test, one operated to exceed the failure threshold, corresponding to a life of 528 hours, and the other two still met the requirements of the technical indicators after completing the test. The measurement data corresponding to the whole life cycle of gyro drift monitoring are as follows: figure 1 shown. In this embodiment, the method for predicting the remaining life of equipment under uncertain degradation measurement data includes the following steps:

[0065] Step 1: Establish an equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com