Recovery method of waste rare earth polishing powder

A technology of rare earth polishing powder and recovery method, applied in the direction of improving process efficiency, silicate, alkali metal silicate, etc., can solve the problems of consuming hydrochloric acid, difficult to industrialize production, etc., and achieve the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

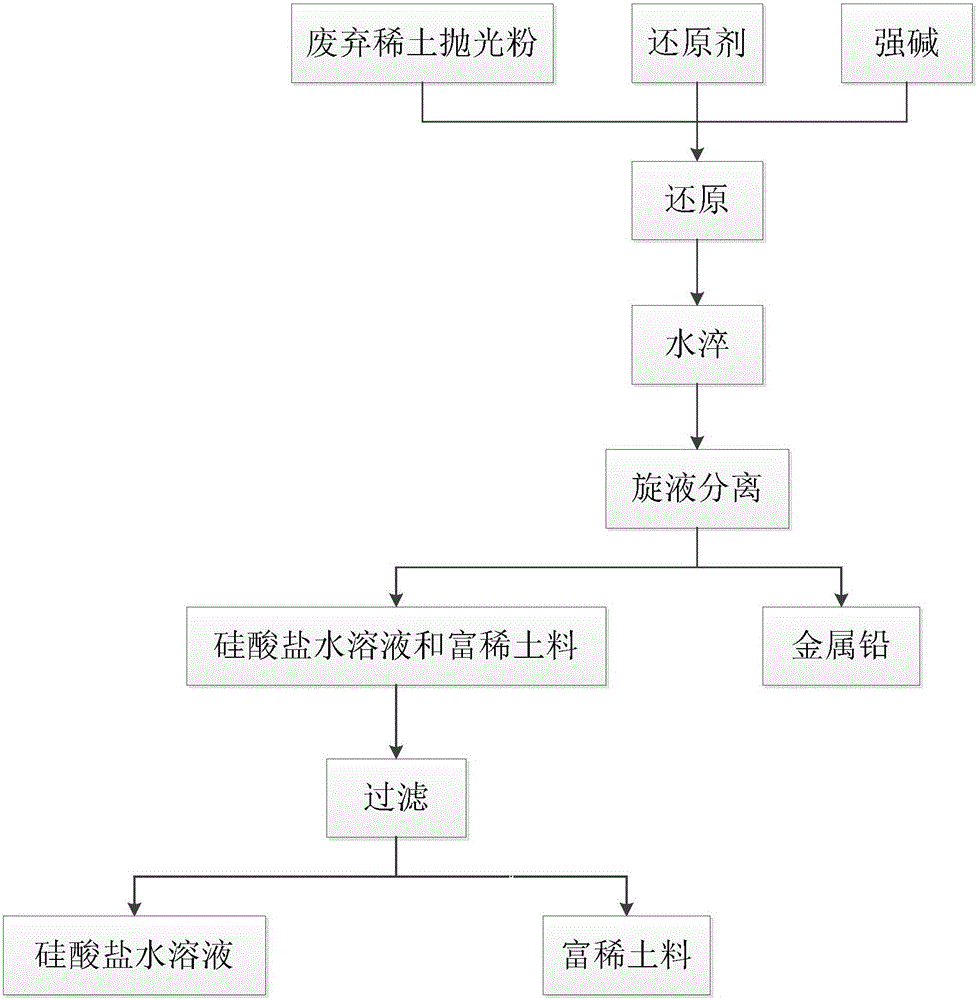

Method used

Image

Examples

Embodiment 1~5

[0044] Crushing, grinding and drying the waste rare earth polishing powder, the particle size is below 20μm;

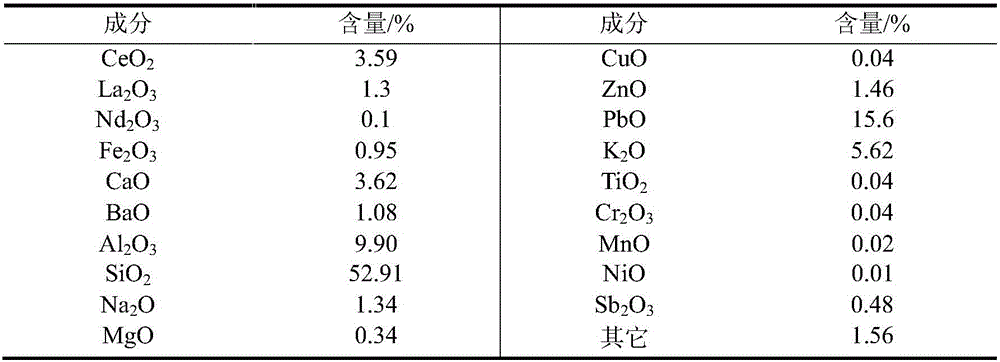

[0045] The chemical composition of waste rare earth polishing powder, as shown in table 1;

[0046] The particle size of activated carbon powder, coke powder or coal powder is below 120 mesh.

[0047] Table 1

[0048]

Embodiment 1

[0050] A kind of recovery method of waste rare earth polishing powder, comprises the following steps:

[0051](1) Weigh 10.013g of waste rare earth polishing powder, 0.194g of coke powder (89% fixed carbon content) and 17.842g of sodium hydroxide, and mix them uniformly in a mixer to obtain a mixture; wherein: by molar ratio, waste rare earth Lead oxide in the polishing powder: solid carbon in the reducing agent = 1: 2.06; in molar ratio, silicon dioxide in the waste rare earth polishing powder: sodium hydroxide = 1: 5.05;

[0052] (2) Place the mixture in a magnesia crucible, place the magnesia crucible in a muffle furnace, and perform a reduction reaction. The reduction reaction temperature is 800° C., and the reduction reaction time is 120 minutes to obtain a reduction product;

[0053] (3) water quenching the reduction product to room temperature to obtain a cooled product;

[0054] (4) The cooled product is subjected to hydrocyclone separation to obtain a mixture of rare...

Embodiment 2

[0057] A kind of recovery method of waste rare earth polishing powder, comprises the following steps:

[0058] (1) Weigh 10.012g of waste rare earth polishing powder, 0.104g of activated carbon powder (fixed carbon content is 99%) and 17.840g of sodium hydroxide, and mix them uniformly in a mixer to obtain a mixture; wherein: by molar ratio, waste rare earth Lead oxide in the polishing powder: solid carbon in the reducing agent = 1: 1.24; in molar ratio, silicon dioxide in the waste rare earth polishing powder: sodium hydroxide = 1: 5.05;

[0059] (2) Place the mixture in a magnesia crucible, place the magnesia crucible in a muffle furnace, and perform a reduction reaction. The reduction reaction temperature is 650° C., and the reduction reaction time is 120 minutes to obtain a reduction product;

[0060] (3) water quenching the reduction product to room temperature to obtain a cooled product;

[0061] (4) The cooled product is subjected to hydrocyclone separation to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com