Nozzle for polycrystalline silicon reduction furnaces with 48 pairs of sticks

A technology of polysilicon and reduction furnace, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of increasing the complexity of the temperature field and flow field of the reduction furnace, and achieve the effect of sufficient and uniform distribution of the reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

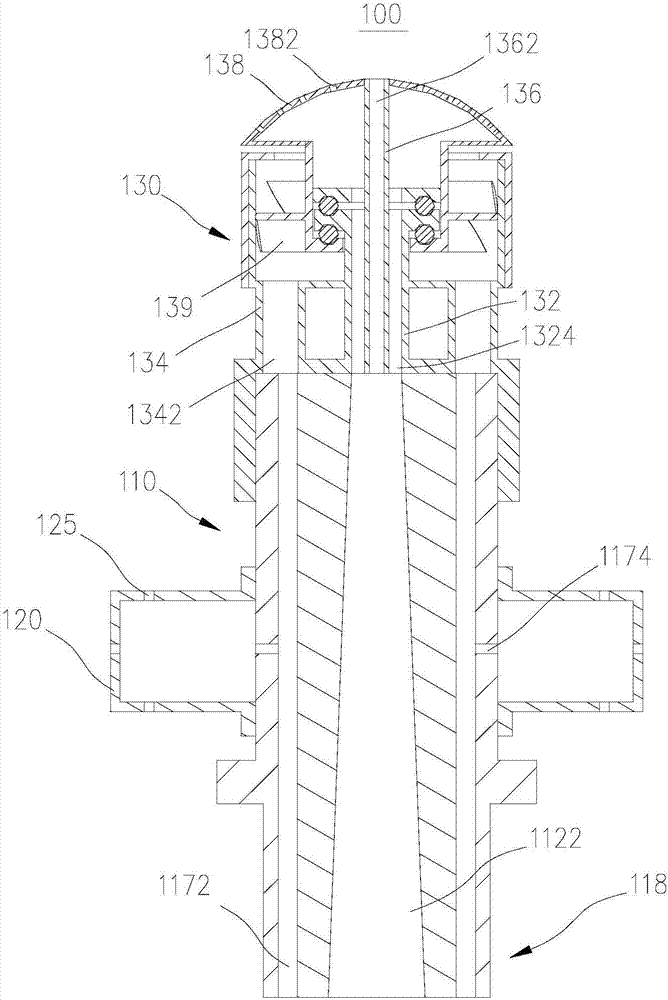

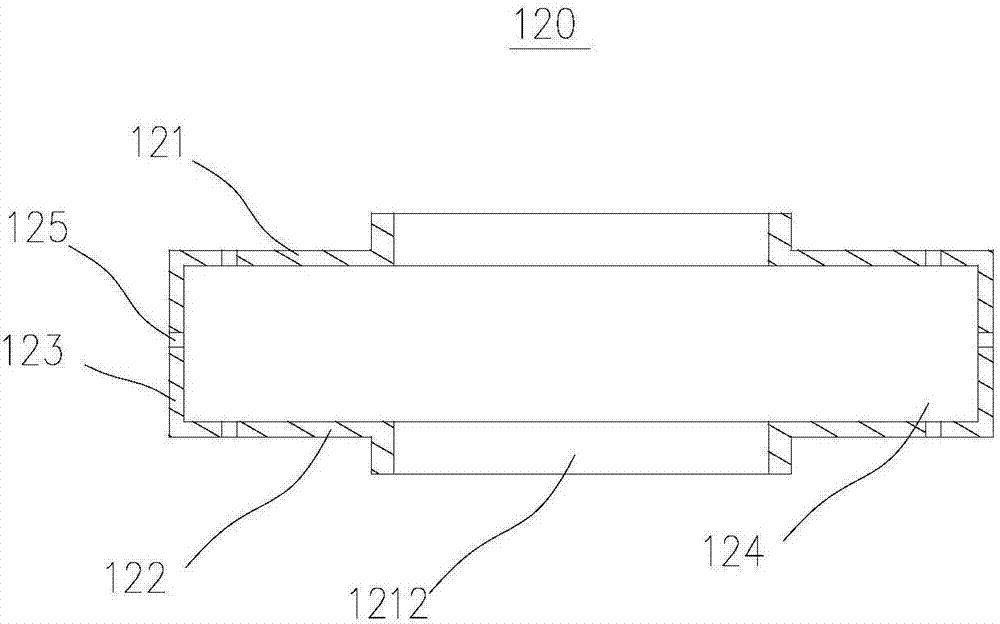

[0044] This embodiment provides a nozzle 100, such as figure 1 , this nozzle 100 is used to inject from the chassis 210 ( Figure 8 ) material gas is charged into the reduction furnace ( Figure 7 ) to carry out the reduction reaction, mainly including the core body 110, the shunt cover 120 and the nozzle 100. The shunt cover 120 is a cylindrical shell structure, which is sheathed on the core body 110 , and the nozzle 100 is connected to the gas outlet end 116 of the core body 110 . The entire nozzle 100 utilizes the spray head 130 and the shunt cover 120 to charge the material gas into the reduction furnace for reaction.

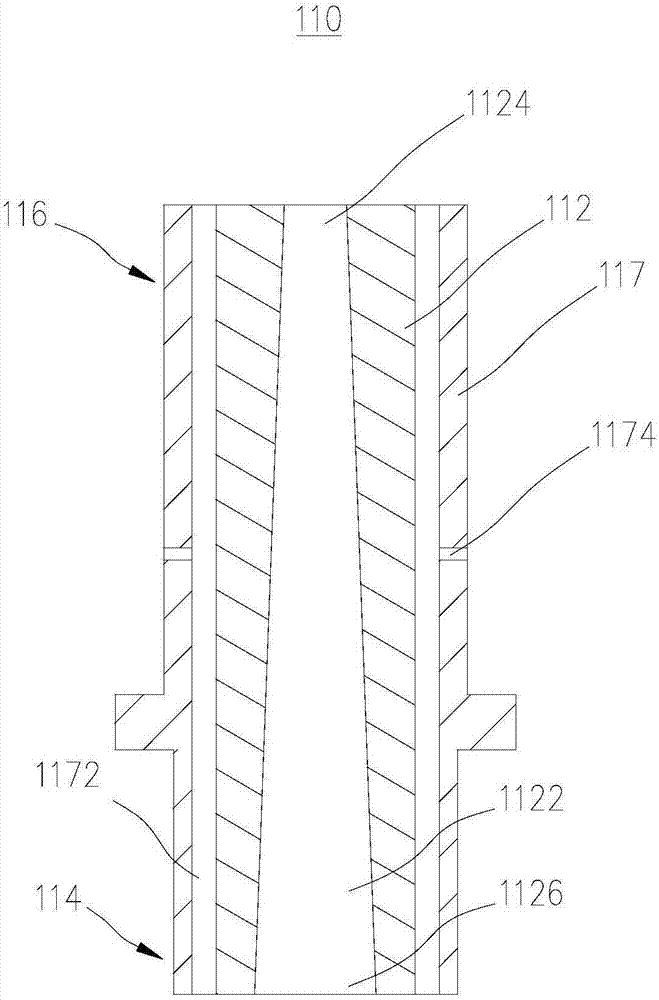

[0045] Such as figure 1 and 2 , the core 110 includes a first inner tube 112 and a first outer tube 117 , and the first outer tube 117 is sheathed on the first inner tube 112 . The first inner tube 112 is provided with a through hole, and the through hole extends along the length direction of the first inner tube 112 to form a main channel 1122 , and t...

Embodiment 2

[0052] Such as Figure 7 and Figure 8 , the present embodiment provides a 48-pair rod polysilicon reduction furnace 200, which includes 48 pairs of rods (not shown in the figure), the chassis 210 and the nozzle 100 provided in Embodiment 1. An air outlet is provided on the chassis 210 , and the nozzle 100 is connected to the air outlet through the connecting portion 118 .

[0053] Since the structures of other components of the reduction furnace are relatively common in the prior art, this embodiment does not introduce the specific structure of the reduction furnace in detail.

[0054] Such as figure 1 , Figure 7 and Figure 8 , The working principle of the 48-pair polysilicon reduction furnace 200 is as follows: the material gas first comes to the chassis 210, and enters the main channel 1122 and the auxiliary channel 1172 from the gas outlet of the chassis 210. The gas in the main channel 1122 is accelerated and enters the shower head 130 from the gas outlet 1124, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com