Macromolecular dry-process denitration agent, and preparation method and application thereof

A denitration agent and polymer technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as ash accumulation and crystallization in economizer air preheaters, failure to meet NOx emission requirements, and shortened equipment service life. , to achieve the effect of reducing maintenance and operating costs, preventing grate embrittlement, and reducing ash accumulation and crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

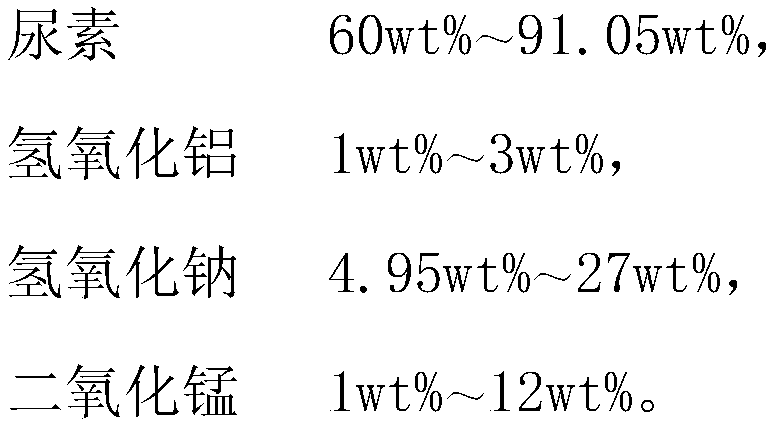

[0031] Polymer dry denitrification agent and its preparation method:

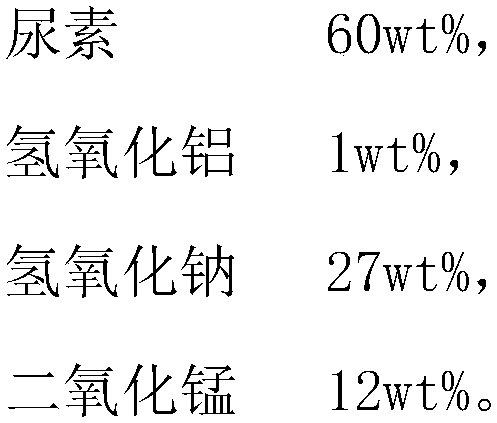

[0032] The polymer dry denitrification agent is composed of the following raw materials by weight percentage, urea 60wt%, aluminum hydroxide 1wt%, sodium hydroxide 27wt%, manganese dioxide 12wt%.

[0033] Among them, urea and sodium hydroxide are reducing agents, aluminum hydroxide is a moisture-proof agent, and manganese dioxide is a catalyst.

[0034] Its preparation method comprises the following steps:

[0035] The first step is to measure and weigh the raw materials in sufficient quantities. Aluminum hydroxide and manganese dioxide do not need to be ground. Under the condition of drying temperature ≤ 15°C, grind urea and sodium hydroxide into fine particles with a mesh size below 200. powder spare;

[0036] The second step is to mix and stir the urea powder below 200 mesh and aluminum hydroxide in proportion after the first step, and the stirring time is 30 minutes to 60 minutes.

[0037] The third ...

Embodiment 2

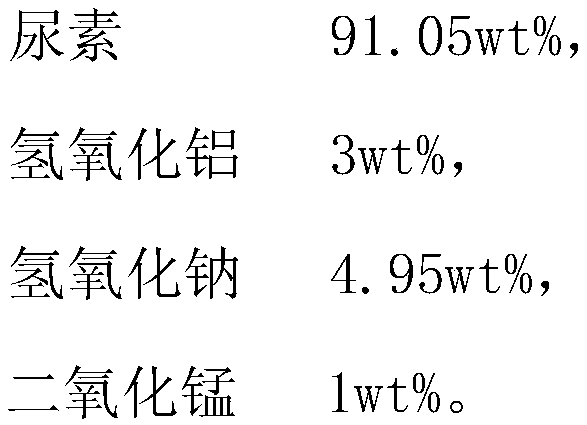

[0045] The polymer dry denitrification agent is composed of the following raw materials in weight percent, urea 91.05wt%, aluminum hydroxide 3wt%, sodium hydroxide 4.95wt%, manganese dioxide 1wt%.

[0046] Its preparation method and application method are the same as in Example 1, and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com