Equipment and method for producing yellow phosphorus from middle-low-grade phosphate ore

A phosphate rock, low-grade technology, applied in cement production, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of complex composition, energy waste, resource waste, etc., achieve uniform flue gas temperature, reduce production costs, improve The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

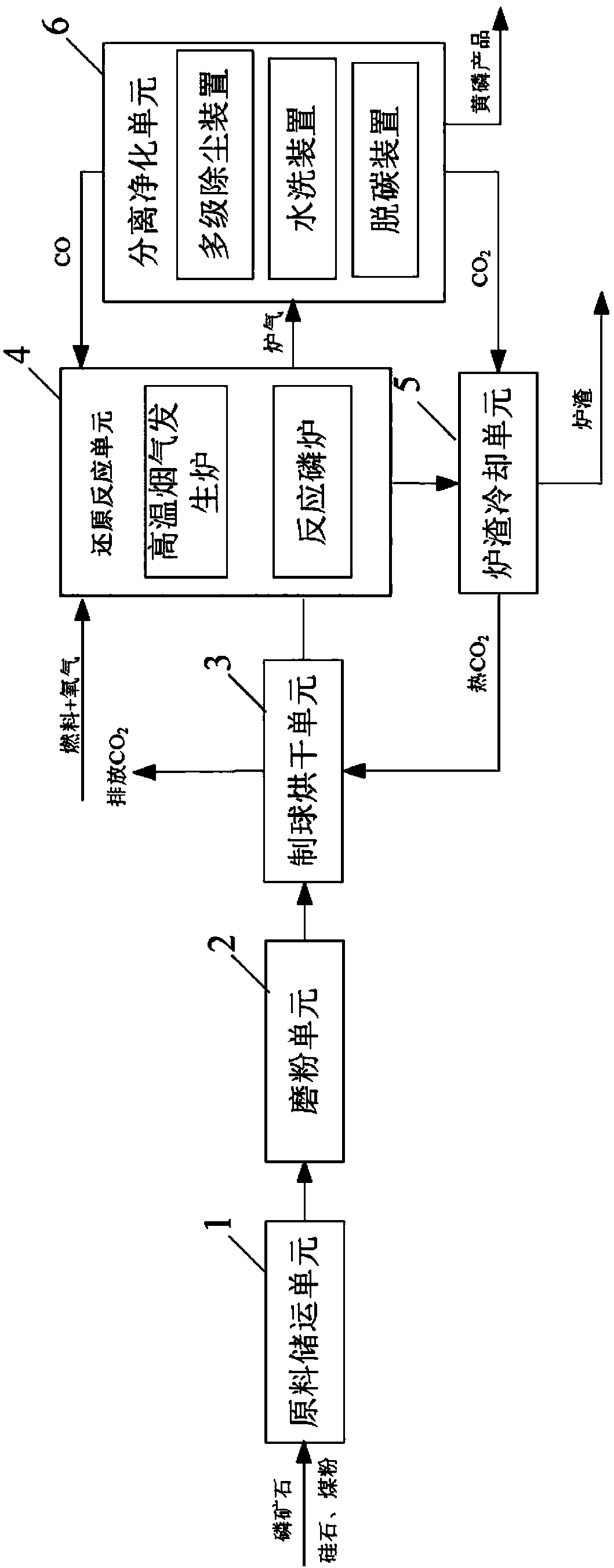

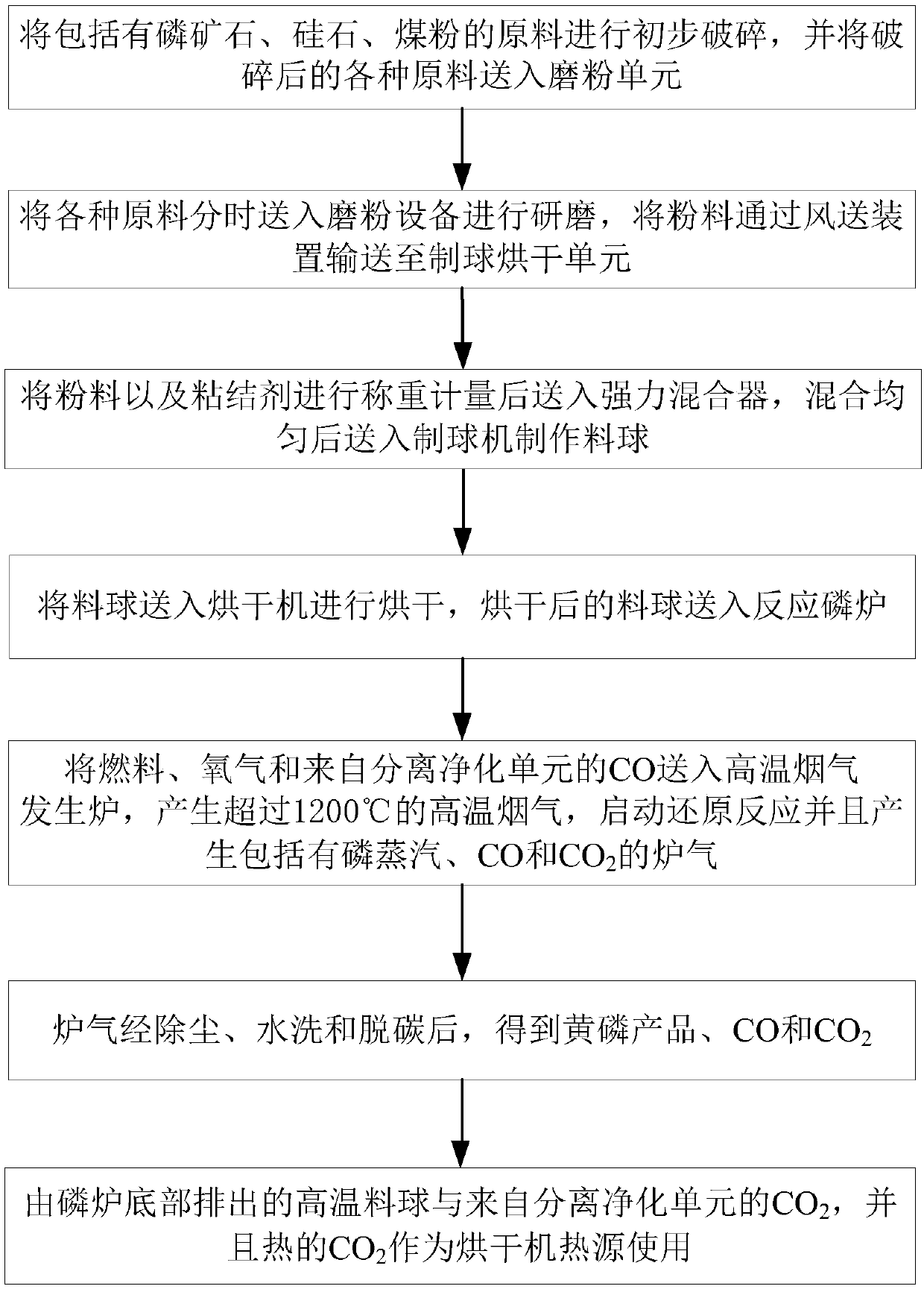

[0040] combine figure 1 As shown, a kind of equipment in the present invention utilizes medium and low-grade phosphate rock to produce yellow phosphorus, which includes: raw material storage and transportation unit 1, milling unit 2, pellet drying unit 3, reduction reaction unit 4, slag cooling unit 5 and separation purification unit 6.

[0041] The raw material storage and transportation unit 1 is configured to store phosphate rock, silica, coal powder (or phosphate rock, silica, coke) in the stockyard, initially crush the raw materials, and send the crushed three raw materials into the Milling unit 2.

[0042] The milling unit 2 includes a milling device and an air delivery device (such as a blower fan) and is configured to: respectively store the raw materials from the raw material storage and transportation unit in each raw material self-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com