Preparation formula and preparation method of coprinus comatus strain

A production method and technology for the chicken leg mushroom, which are applied in the fields of botanical equipment and methods, mushroom cultivation, gardening, etc., can solve the problems of high cost, low benefit, and low output of the chicken leg mushroom, maximize profits, reduce the cost of raw materials, reduce bacteria, etc. The effect of strong silk growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

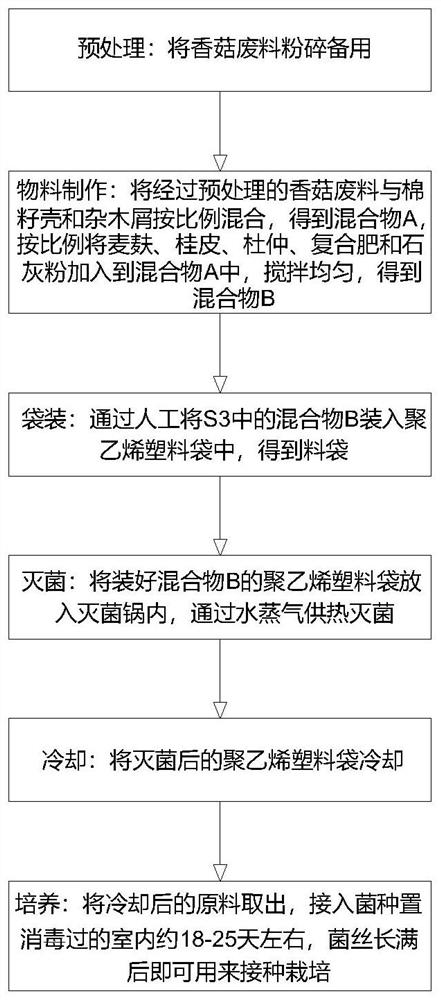

[0019] see figure 1 , a kind of bacterial strain preparation method of chicken leg mushroom, comprising the following specific steps:

[0020] S1, pretreatment: shredding the shiitake mushroom waste for use.

[0021] Specifically, the shiitake mushroom waste is placed in a pulverizer and pulverized to a particle size of 2-6 mm.

[0022] S2, material preparation: mix the pretreated shiitake mushroom waste with cottonseed husks and miscellaneous sawdust to obtain a mixture A, add wheat bran, cinnamon, eucommia, compound fertilizer and lime powder to the mixture A in proportion, and stir evenly to obtain a mixture B.

[0023] Specifically, in step S2, before the main ingredients are mixed, the waste mushrooms are washed with clean water to remove impurities, and then soaked in clean water for 1-2 hours, then removed and drained. The water content of mixture B is 60%-65%, and the pH is 7.0-8.0.

[0024] S3, bag packing: The material bag is obtained by manually packing the mixt...

Embodiment 2

[0034] A method for producing a bacterial strain of the mushroom, comprising the following specific steps:

[0035] S1, pretreatment: 50% shiitake mushroom waste is crushed for use.

[0036] Specifically, the shiitake mushroom waste is placed in a pulverizer and pulverized to a particle size of 2-6 mm.

[0037] S2, material preparation: mix the pretreated 50% shiitake mushroom waste with 10% cottonseed husks and 10% miscellaneous sawdust to obtain a mixture A, 5% wheat bran, 5% cinnamon, 3% eucommia, 4% compound fertilizer and 1 % lime powder was added to mixture A, and stirred well to obtain mixture B.

[0038] Specifically, in step S2, before the main ingredients are mixed, the waste mushrooms are washed with clean water to remove impurities, and then soaked in clean water for 1-2 hours, then removed and drained. The water content of mixture B is 60%-65%, and the pH is 7.0-8.0.

[0039] S3, bag packing: The material bag is obtained by manually packing the mixture B in S3 ...

Embodiment 3

[0049] A method for producing a bacterial strain of the mushroom, comprising the following specific steps:

[0050] S1, pretreatment: 55% shiitake mushroom waste is crushed for use.

[0051] Specifically, the shiitake mushroom waste is placed in a pulverizer and pulverized to a particle size of 2-6 mm.

[0052] S2, material production: mix pretreated 55% shiitake mushroom waste with 20% cottonseed husks and 13% miscellaneous sawdust to obtain mixture A, which is mixed with 7.5% wheat bran, 7.5% cinnamon, 4% eucommia, 5% compound fertilizer and 2 % lime powder was added to mixture A, and stirred well to obtain mixture B.

[0053] Specifically, in step S2, before the main ingredients are mixed, the waste mushrooms are washed with clean water to remove impurities, and then soaked in clean water for 1-2 hours, then removed and drained. The water content of mixture B is 60%-65%, and the pH is 7.0-8.0.

[0054] S3, bag packing: The material bag is obtained by manually packing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com