Compound furnace arch and compound secondary air structure for cooperatively controlling generation of nitrogen oxide (NOX)

A nitrogen oxides, collaborative control technology, applied in lighting and heating equipment, non-flammable liquid/gas transportation, combustion methods, etc., can solve the problems of low removal efficiency, lack of active control, high operating costs, and achieve NOX The reduction reaction is sufficient, the mixing is strengthened, and the effect of avoiding premature mixed combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

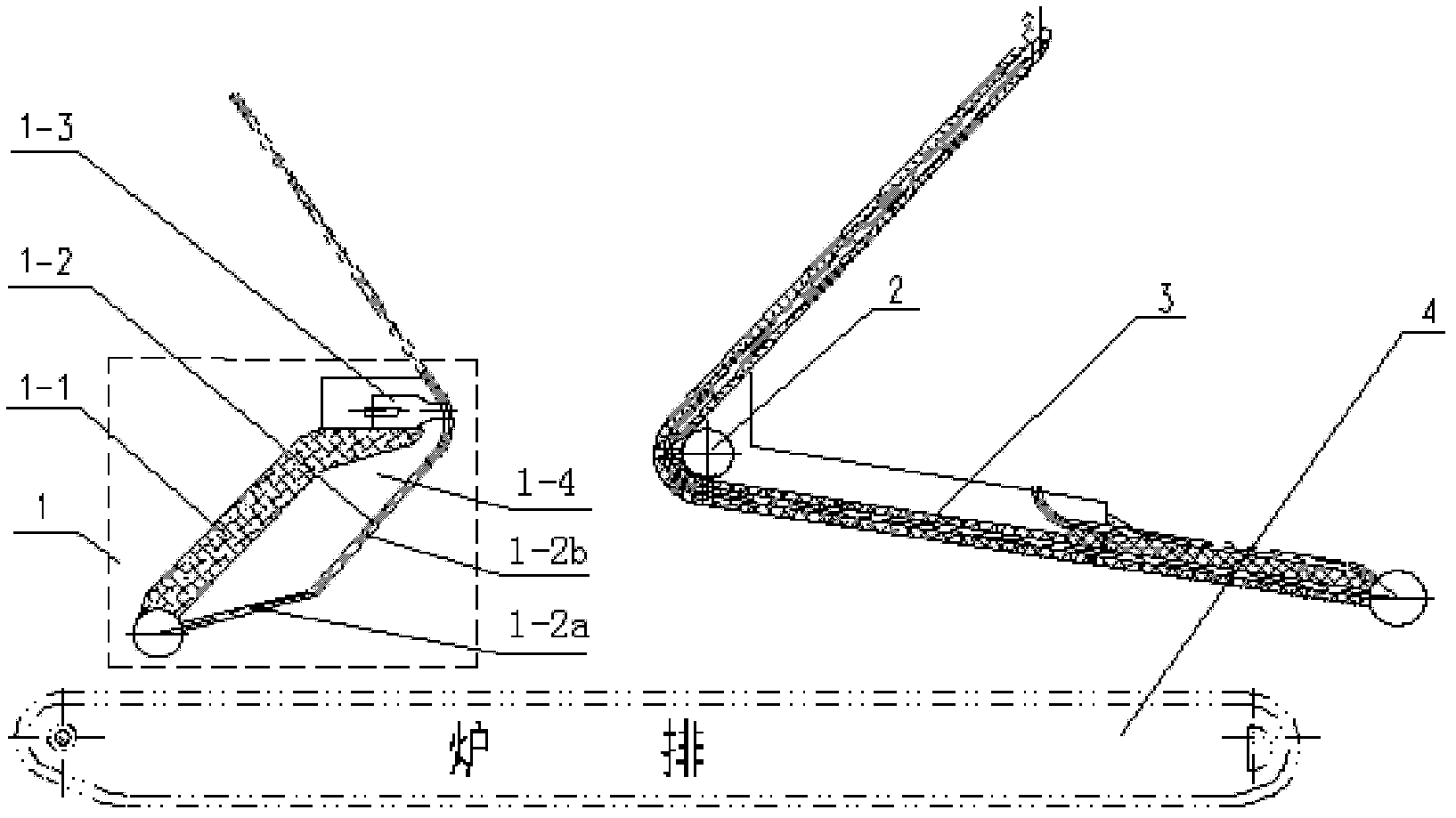

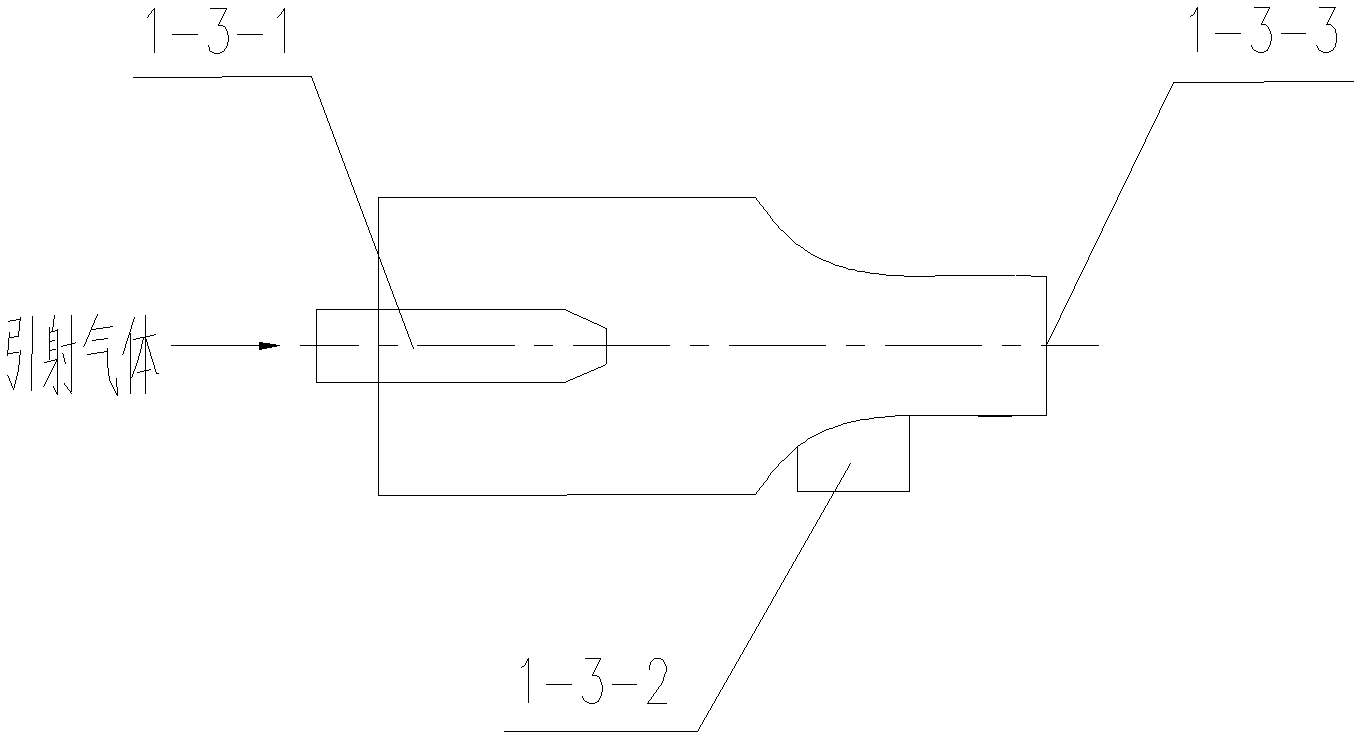

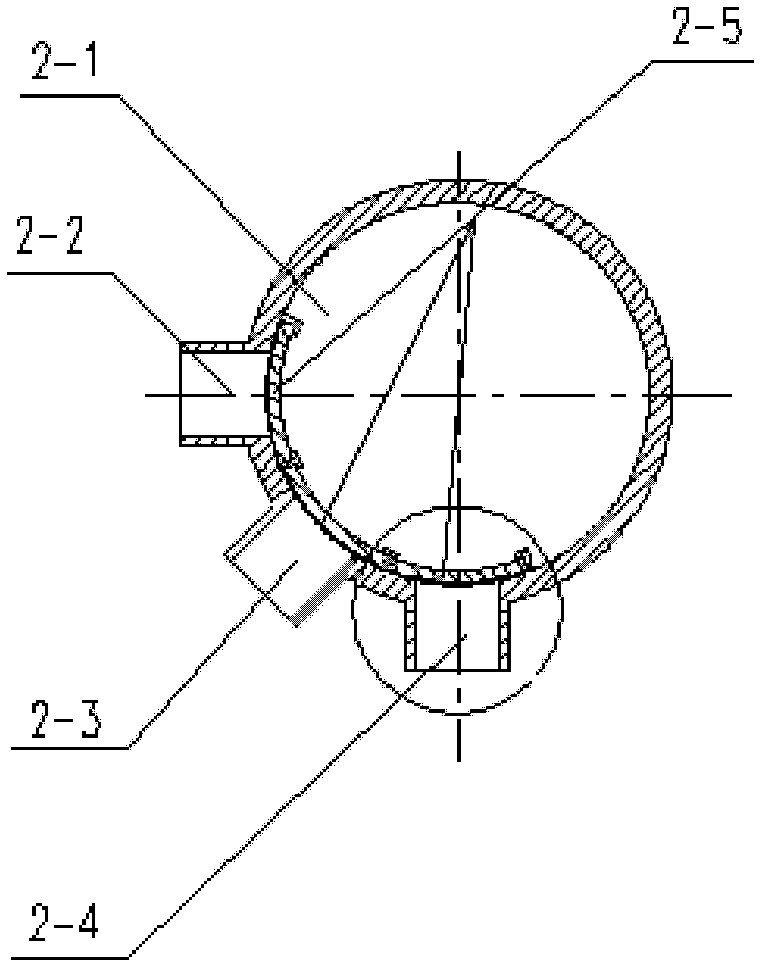

[0024] Such as figure 1 As shown, the present invention is a composite furnace arch and composite secondary air structure that synergistically controls the formation of nitrogen oxides, including a front arch 1 and a rear arch 3, and the water-cooled wall 1-2 of the front arch 1 protrudes toward the interior of the furnace so that A cavity 1-4 is formed between it and the front arch furnace wall 1-1, and an ejector 1-3 is equipped with at the top outlet of the cavity 1-4. The front arch furnace wall 1-1 is made of refractory material, the lower part 1-2a of the water-cooled wall 1-2 adopts a smooth tube water-cooled wall, leaving gaps between the tube bundles, and the upper part 1-2b adopts a membrane-type water-cooled wall, The reducing volatile gas generated by pyrolysis can enter the cavity 1-4 from the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com