Device and method for metal oxide fine ore gas-based reduction

An oxide powder, gas-based technology, applied in the field of metallurgical equipment, can solve the problems of cumbersome procedures, expensive hydrogen production costs, difficult to achieve, etc., and achieve the effect of reducing procedures, equipment investment and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

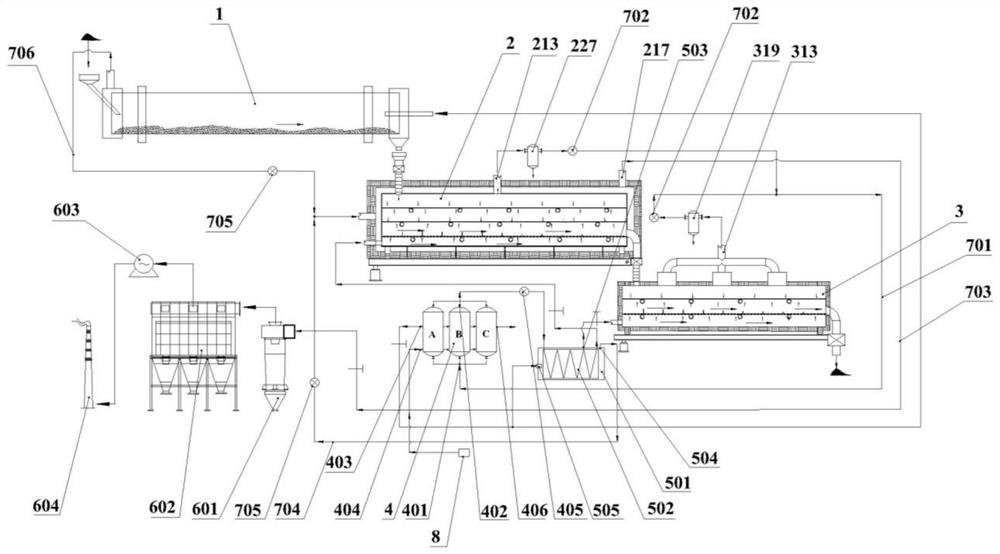

[0088] A device for gas-based reduction of metal oxide powder ore, which sequentially includes an oxidation roasting system 1, a gas-based pre-reduction system 2, and a gas-based deep reduction system 3 in sequence; it also includes a molecular sieve pressure swing adsorption system 4, a pure hydrogen flame trap Heat exchange heating furnace system and dust removal and smoke exhaust system;

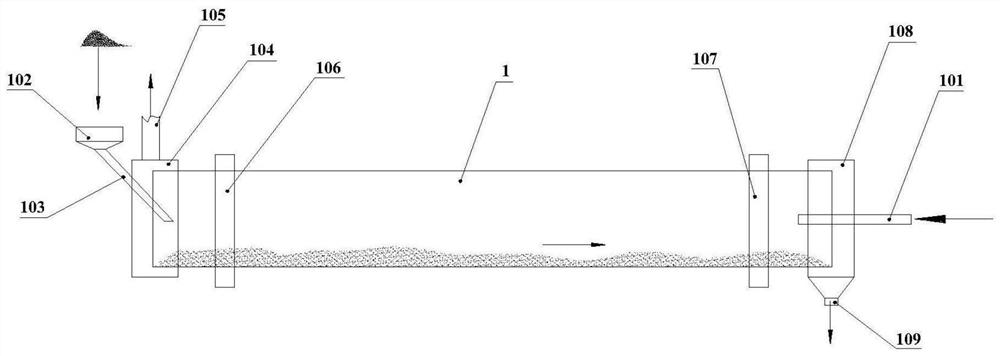

[0089] The oxidation roasting system 1 includes a CO gas burner 101; a kiln tail cover 104 is set at the feed end, and a kiln head cover 108 is set at the discharge end; the kiln body is supported by a kiln tail support ring 106 and a kiln head support ring 107; The kiln tail cover 104 is connected to the feeding hopper 102 through the feed pipe 103; the kiln tail cover 104 is provided with a smoke exhaust port 105; the kiln head cover 108 is provided with a high temperature material outlet 109.

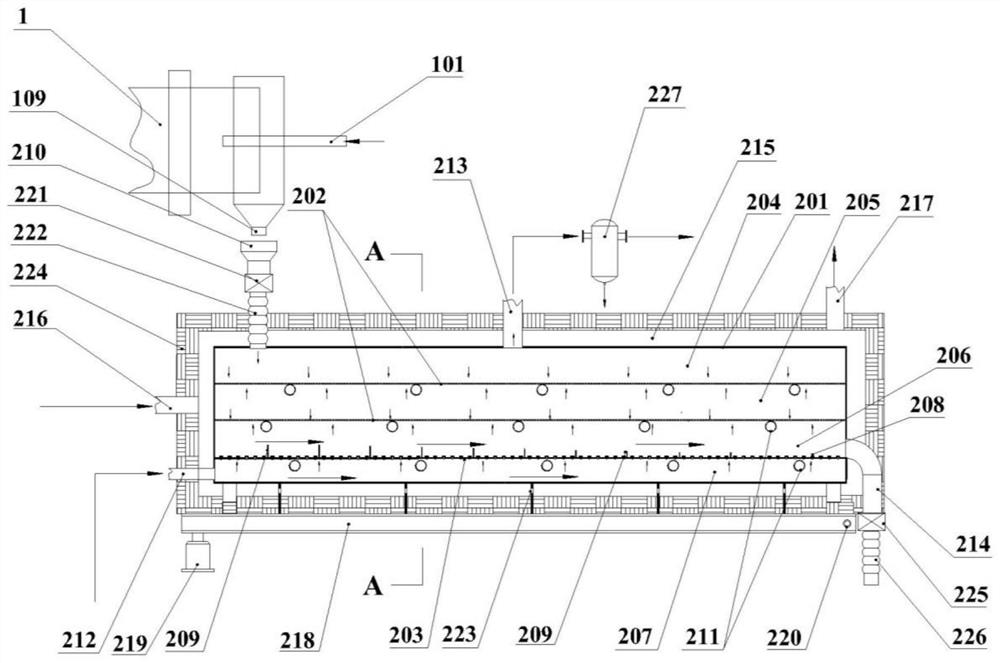

[0090] The gas-based pre-reduction system 2 includes a pre-reduction furnace cylinder body 2...

Embodiment 2

[0121] The gas-based reduction was performed using the apparatus in Example 1.

[0122] Grade TFe: 71.5%, fineness 300-500 mesh Liaoning Jianping ultra-pure iron concentrate powder. Take 100kg of ore sample, use oxidation roasting system 1 to oxidize and roast it, heat it to 970°C, put it into ¢1000mm×4m pre-reduction furnace cylinder 201, adjust the installation angle of pre-reduction furnace cylinder 201 to 0.3°, place 99.9% pure H obtained by electrolysis of water 2 , using a gas electric heater, the H 2 After flame insulation heating to 780°C, pressurize to a pressure of 18KPa, put it into the pre-reduction furnace cylinder 201 for pre-reduction, after 1.6 hours of reduction time, the temperature of reduced iron (DRI) is 710°C, take samples to protect after cold pressing , the detection index is:

[0123] Then add DR I at a temperature of 710°C into the deep reduction furnace cylinder 301 with a diameter of ¢800mm×2.5m in a sealed manner. The installation angle of the d...

Embodiment 3

[0128] The gas-based reduction was performed using the apparatus in Example 1.

[0129] Grade TFe: 70.24%, fineness 300-400 mesh Liaoning Jianping iron ore concentrate powder. Take 100kg of ore sample, use oxidation roasting system 1 to oxidize and roast it, heat it to 990°C, put it into ¢1000mm×4m pre-reduction furnace cylinder 201, adjust the installation angle of pre-reduction furnace cylinder 201 to 0.25°, set 99.9% pure H obtained by electrolysis of water 2 , using a gas electric heater, the H 2 After flame insulation heating to 780°C, pressurize to 16KPa, put it into the pre-reduction furnace cylinder 201 for pre-reduction, after 1.6 hours of reduction time, the temperature of reduced iron (DRI) is 721°C, take samples to protect after cold pressing , the detection index is:

[0130] Then add DR I at a temperature of 721°C into the deep reduction furnace cylinder 301 with a diameter of ¢800mm×2.5m in a sealed manner. The installation angle of the deep reduction furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com