Waste acid reduction pneumatic mixing device

A pneumatic mixing and mixing tube technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of high cost of waste acid treatment, difficulty in mixing fully, large consumption of iron powder, etc., and achieve saving and reduction The effect of cost, safe and convenient use, and simple main structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

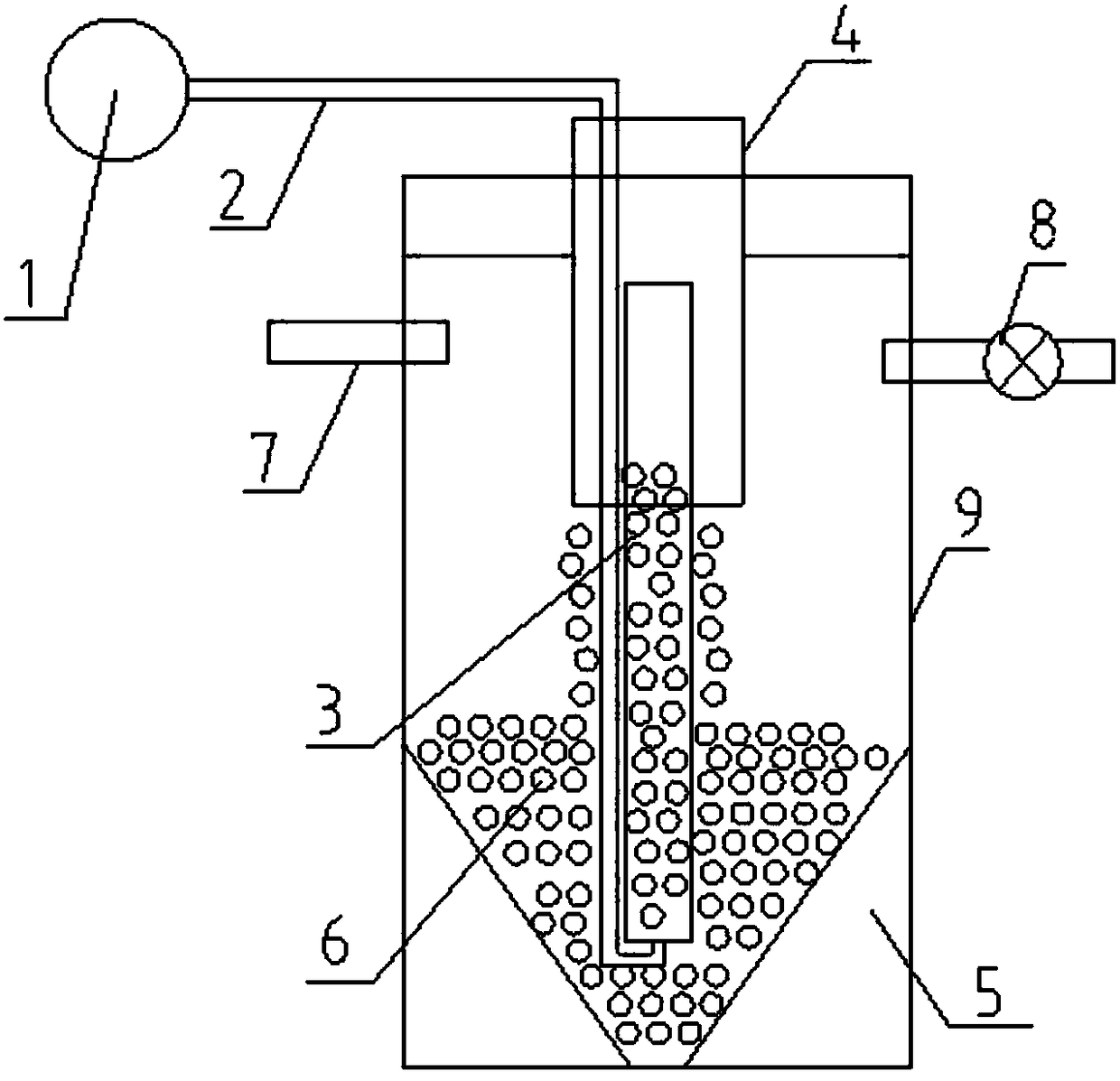

[0014] The main structure of the waste acid reduction pneumatic mixing device involved in this embodiment includes: air compressor 1, air pipeline 2, mixing pipe 3, baffle plate 4, inclined plate 5, iron powder 6, feed inlet 7, outlet valve 8 and Reaction tank 9; inclined plates 5 are arranged around the bottom of the reaction tank 9 to form an inverted cone structure at the bottom of the reaction tank 9, and the bottom of the reaction tank 9 is filled with iron powder 6 for reducing waste acid. The powder 6 concentrates and settles in the middle of the reaction tank 9 under the guidance of the inclined surface of the inclined plate 5. A vertically placed mixing tube 3 is arranged directly above the middle of the reaction tank 9, and one end of the air pipe 2 for transporting air extends to The bottom end of the mixing tube 3 and the other end are connected to the air compressor 1, and the air generated by the air compressor 1 is transported to the bottom of the reaction tank 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com