Waste acid reduction hydraulic power mixing device

A mixing device and hydraulic technology, which is applied in the field of waste acid reduction hydraulic mixing device, can solve the problems of high cost of waste acid treatment, difficulty in stirring and mixing fully, and large consumption of iron powder, etc., so as to save reduction cost and be safe and convenient to use , the effect of simple main structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

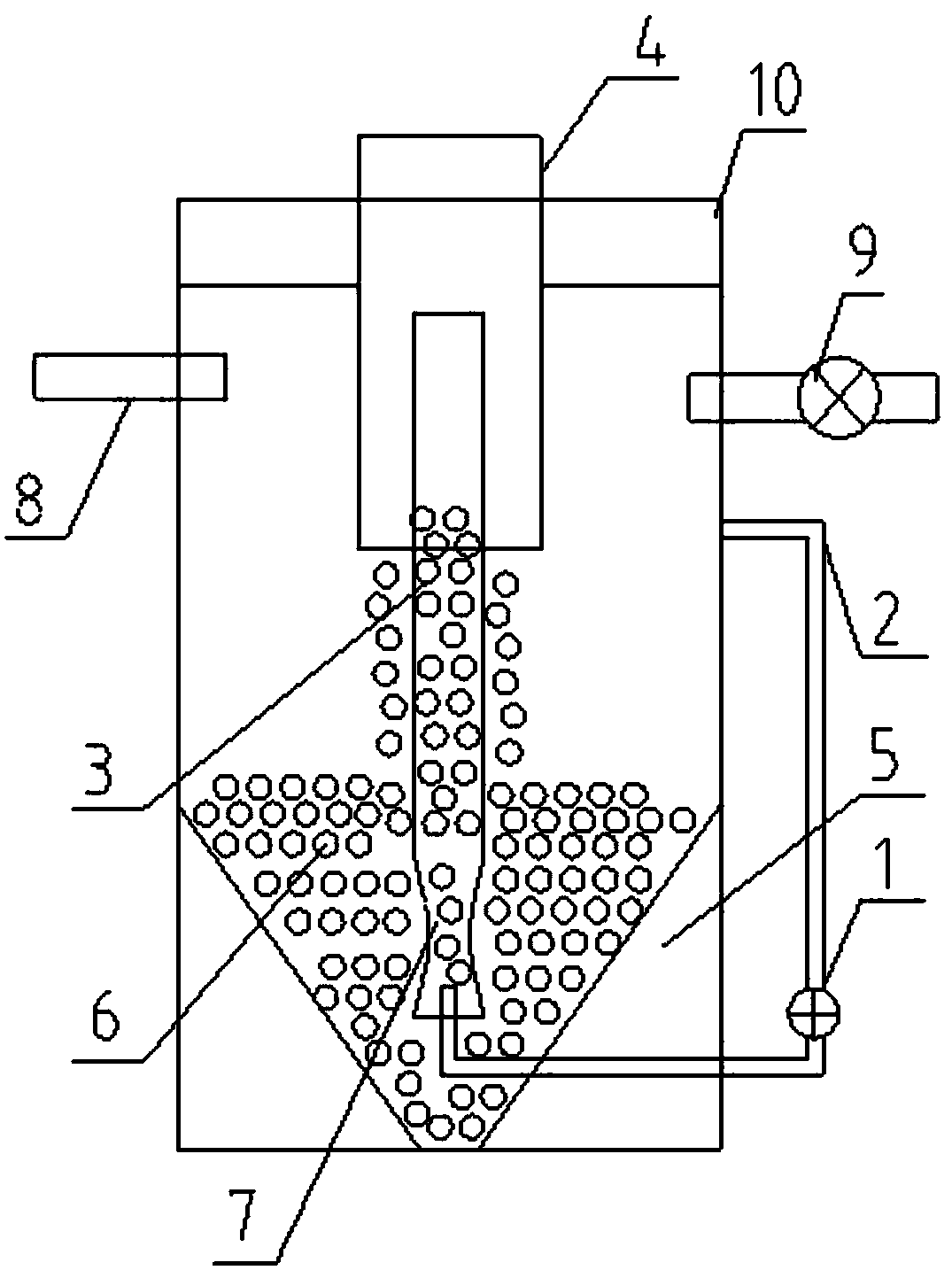

[0013] The main structure of the waste acid reduction hydraulic mixing device involved in this embodiment includes: circulation pump 1, return pipe 2, mixing pipe 3, baffle plate 4, inclined plate 5, iron powder 6, throat pipe 7, feed port 8, exhaust The outlet 9 and the reaction tank 10 are provided with inclined plates 5 around the bottom of the reaction tank 10 to form an inverted cone-shaped structure at the bottom of the reaction tank 10. The bottom of the reaction tank 10 is filled with iron powder for reducing waste acid 6. The iron powder 6 concentrates and settles in the middle of the reaction tank 10 under the guidance of the inclined surface of the sloping plate 5. A vertical throat 7 is arranged directly above the middle of the reaction tank 10. The throat 7 is narrow in the middle and has upper and lower ends. Wide structure, and the upper end of the throat pipe 7 is connected with the lower port of the mixing pipe 3, the throat pipe 7 is used to strengthen the jet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com