A kind of method that carvacrol microemulsion system prepares nano-silver

A carvacrol and nano-silver technology, applied in the nano field, can solve problems such as environmental pollution and toxic compounds, and achieve the effects of good dispersibility and green preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of nano-silver of the present invention, comprises the following steps:

[0028] (1) Add carvacrol to deionized water, then add surfactant Tween 80, stir under normal temperature, make it mix evenly, the mass concentration of carvacrol is 0.5%, the addition amount of Tween is carvacrol quality 20% of.

[0029] (2) Adopting a high-pressure homogenizer to homogenize the mixed solution obtained in step (1), the homogenization pressure is 500MPa, and the homogenization times are 2 to 4 times to obtain carvacrol microemulsion;

[0030] (3) Take a certain amount of solid silver nitrate, gradually add dilute ammonia water dropwise in silver nitrate, shake while adding dropwise, until the precipitate that generates is all dissolved, obtain silver ammonia solution;

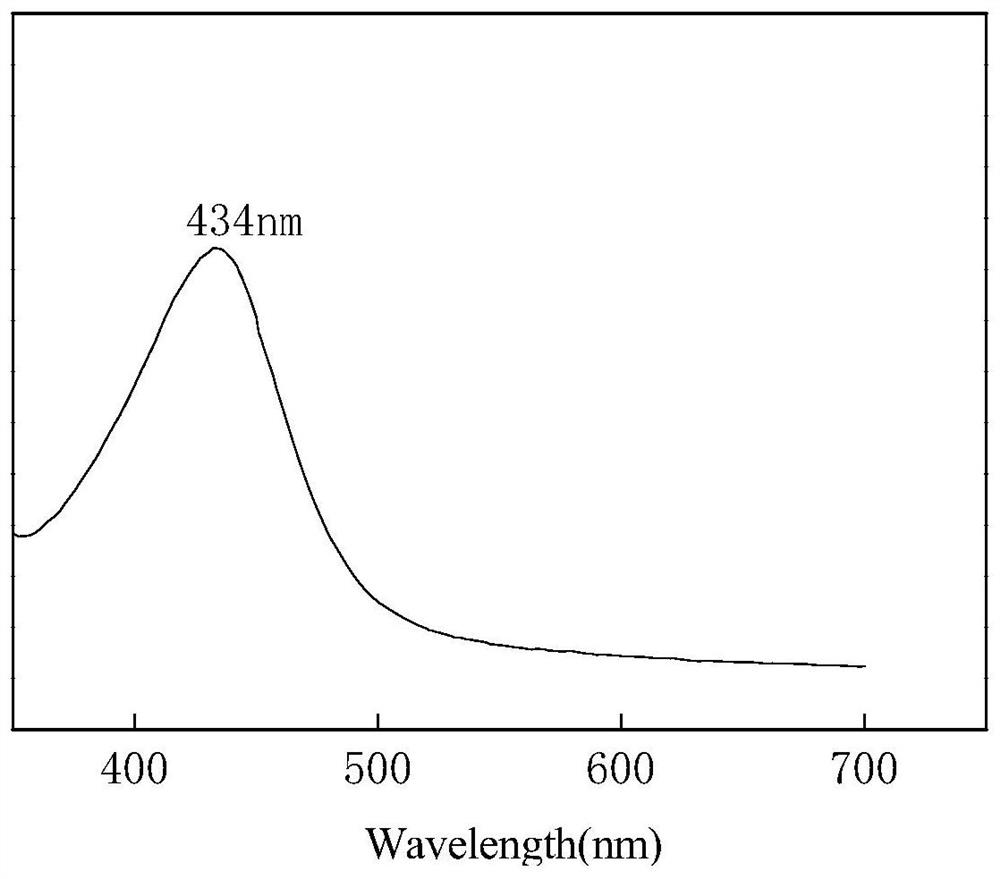

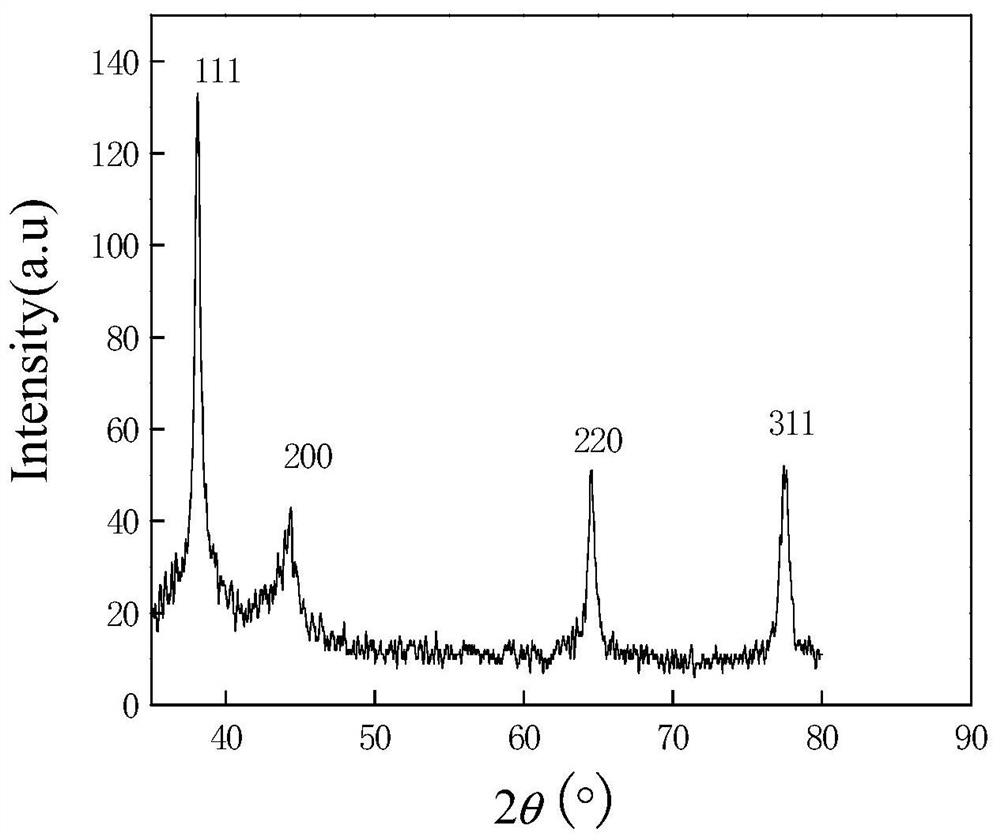

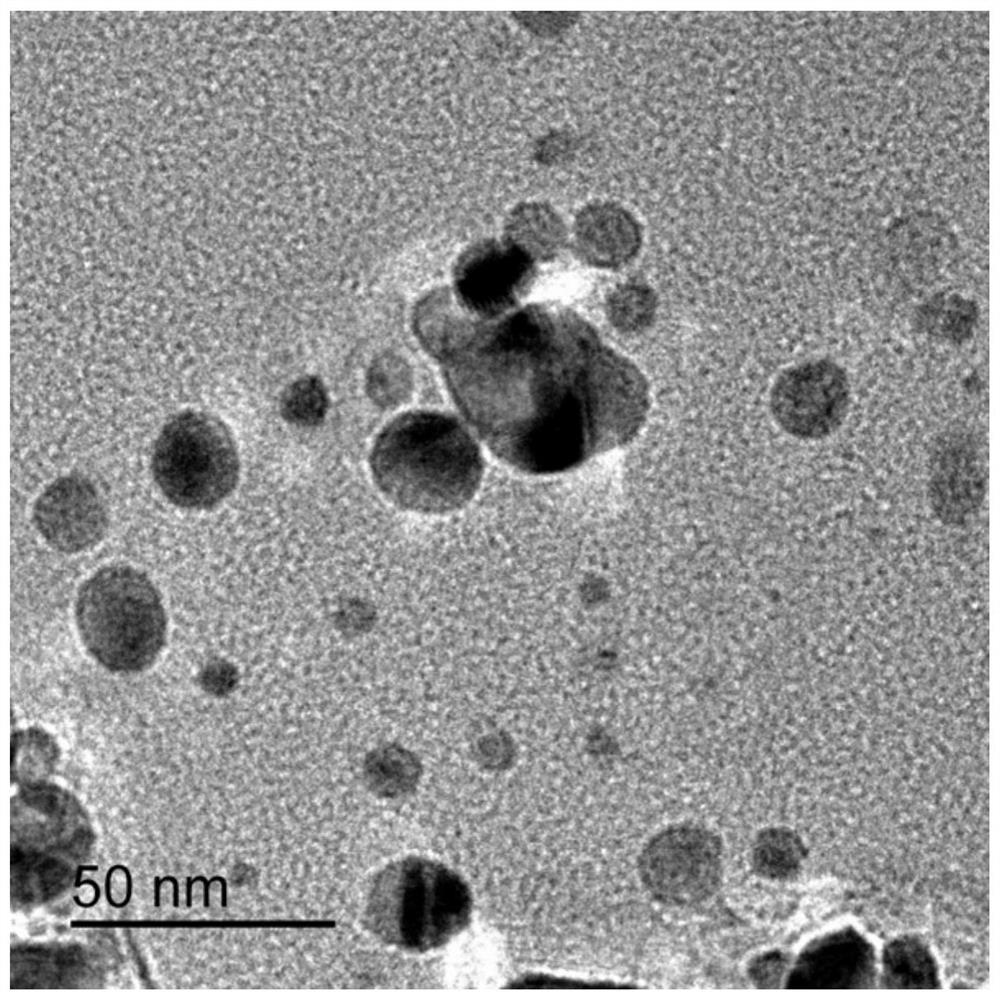

[0031] (4) A certain amount of silver-ammonia solution was added dropwise into 100 mL of carvacrol microemulsion, sealed, and stirred on a magnetic stirrer until the color was dark brow...

Embodiment 1

[0035] 1) Carvacrol is added to deionized water, then surfactant Tween 80 is added, stirred at room temperature to make it evenly mixed, the mass concentration of carvacrol is 0.5%, and the amount of Tween added is 1 / 2 of the carvacrol quality. 20%.

[0036] 2) using a high-pressure homogenizer to homogenize the mixed solution obtained in step (1), the homogenization pressure is 500MPa, and the homogenization times are 4 times to obtain the oil-in-water type carvacrol microemulsion;

[0037] 3) Take a certain amount of solid silver nitrate, gradually add dilute ammonia water dropwise in silver nitrate, shake while dropping, until the precipitates generated are all dissolved, and obtain silver ammonia solution;

[0038] 4) A certain amount of silver ammonia solution was added dropwise into 100mL carvacrol microemulsion, sealed, and stirred on a magnetic stirrer until the color was dark brown and no longer deepened, and a suspension containing silver particles was obtained. The...

Embodiment 2

[0045] 1) Carvacrol is added to deionized water, then surfactant Tween 80 is added, stirred at room temperature to make it evenly mixed, the mass concentration of carvacrol is 0.5%, and the amount of Tween added is 1 / 2 of the carvacrol quality. 20%.

[0046] 2) using a high-pressure homogenizer to homogenize the mixed solution obtained in step (1), the homogenization pressure is 500MPa, and the homogenization times are 3 times to obtain the oil-in-water type carvacrol microemulsion;

[0047] 3) Take a certain amount of solid silver nitrate, gradually add dilute ammonia water dropwise in silver nitrate, shake while dropping, until the precipitates generated are all dissolved, and obtain silver ammonia solution;

[0048] 4) A certain amount of silver ammonia solution was added dropwise into 100mL carvacrol microemulsion, sealed, and stirred on a magnetic stirrer until the color was dark brown and no longer deepened, and a suspension containing silver particles was obtained. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com