Micro-charge water spray waste gas treatment method

A water spray and waste gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of saturated spray water pollution, insoluble volatile organic pollutants insoluble in water, etc., and save water resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

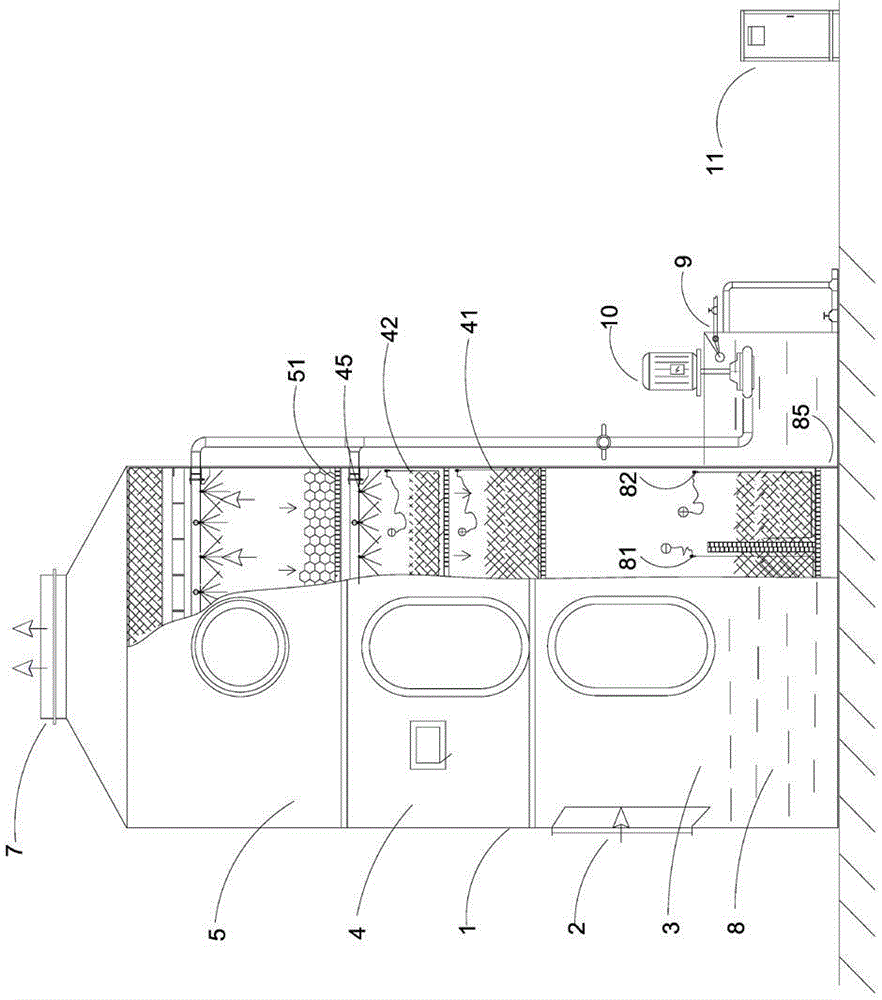

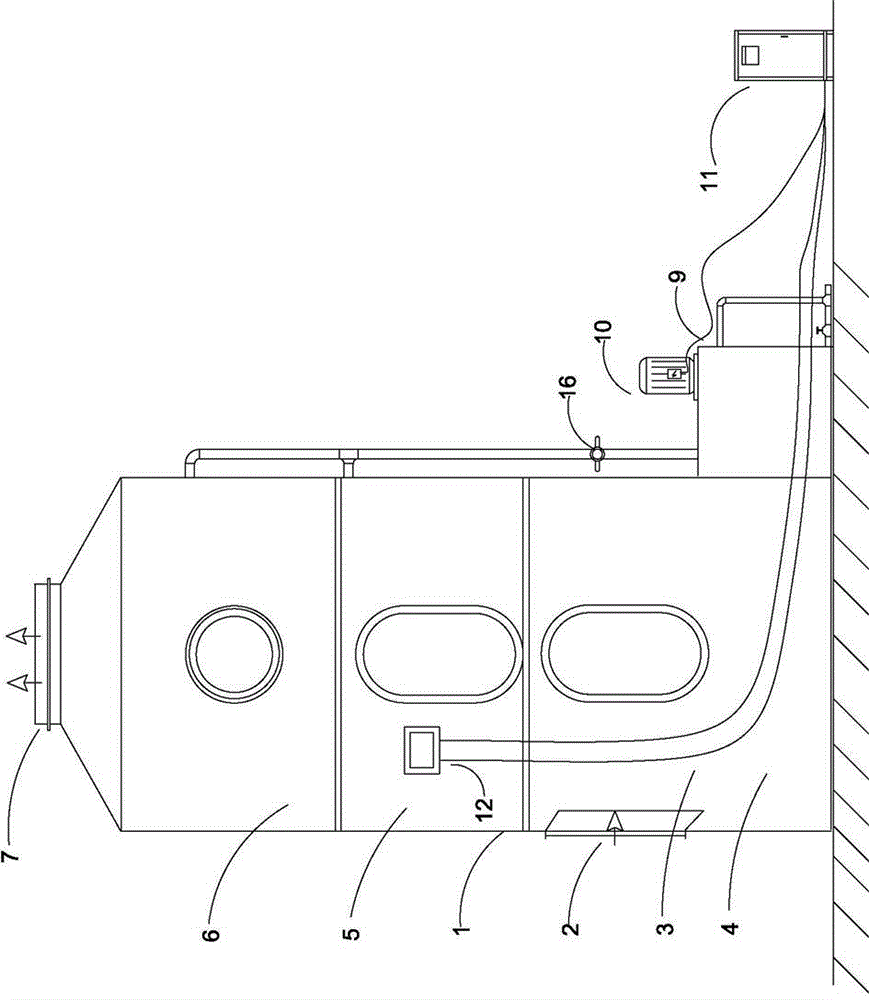

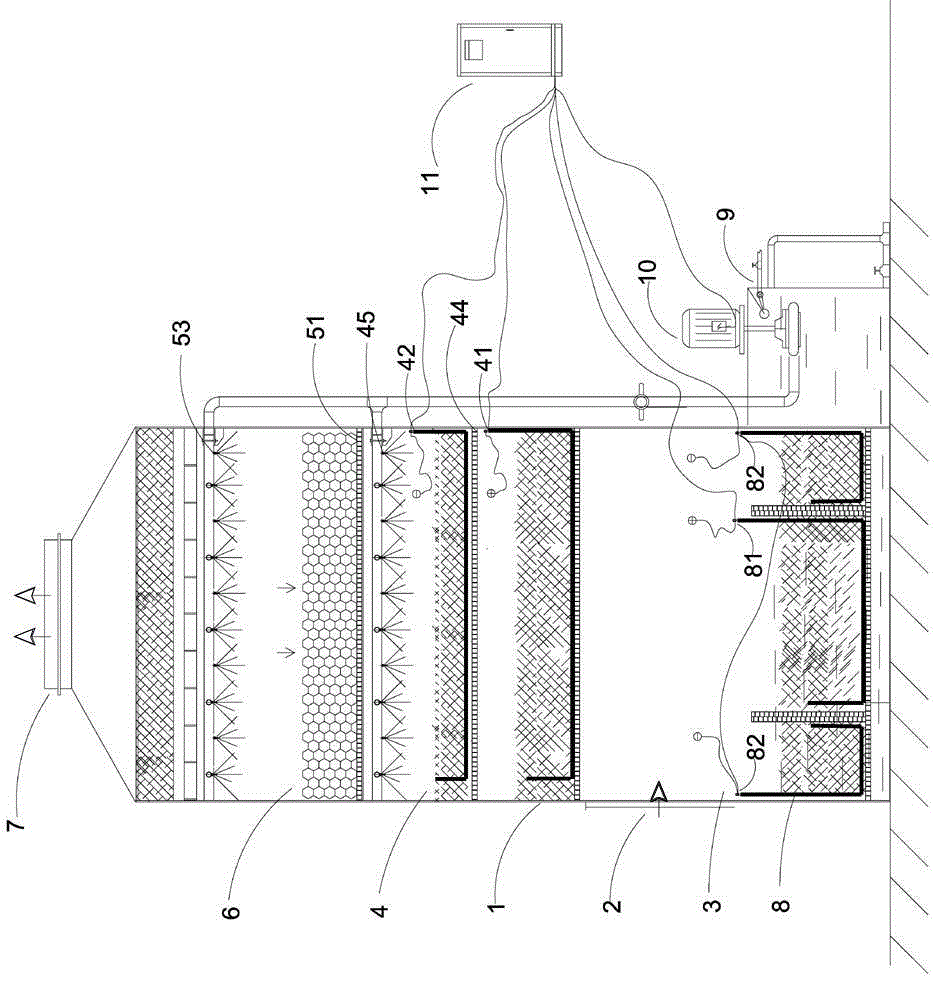

[0024] Embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0025] Refer below Figure 1 to Figure 3 A method for treating waste gas by micro-charged water spraying according to an embodiment of the present invention is described.

[0026] Such as Figure 1 to Figure 3 As shown, a kind of micro-charged water spray treatment exhaust gas method described in the present invention, through the following steps:

[0027] Step 1: exhaust gas enters from the air inlet 2 of the reaction tower body 1;

[0028] Step 2: The exhaust gas continues to rise under the action of suction; the exhaust gas passes through the micro-charge field to form exhaust gas with polar particles, and intercepts and captures the exhaust gas with polar particles;

[0029] Step 3: Spray and rinse again, so that the waste gas with polar particles adheres to the liquid water, and falls to the water storage micro-charge reaction chamber 8 for precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com