Method for cycle purification of uranium in Purex process

A process and concentration technology, applied in chemical instruments and methods, nuclear engineering, radioactive purification, etc., can solve the problems of easy generation of azide acid, the purification effect needs to be further strengthened, etc., and achieve the effect of complete reduction reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

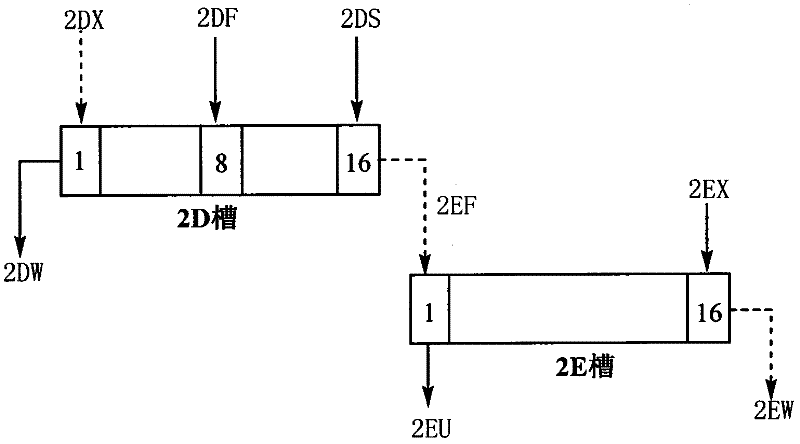

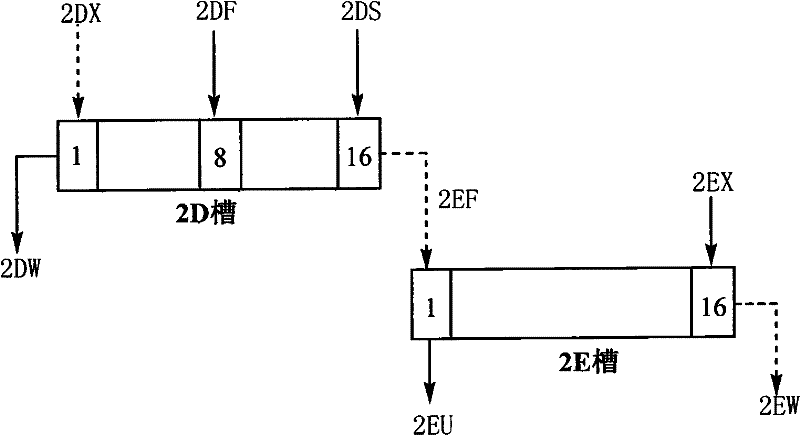

[0014] figure 1 It is a flow chart of the uranium purification cycle process. This example is to simulate the uranium purification cycle bench experiment after 1CU feed liquid is pretreated and seasoned. The 1CU material liquid pretreatment process is to carry out heat preservation pretreatment under the condition of low acid and high temperature, and oxidize tetravalent neptunium in 1CU to pentavalent neptunium which cannot be extracted by 30% TBP / kerosene. The process conditions of the 2D tank are: 8 stages of extraction, 8 stages of washing, compared to 2DF: 2DX: 2DS = 1: 0.55: 0.065, and the composition of 2DS detergent is 0.05mol / L DMHAN-0.05mol / L MMH-1mol / L HNO 3 . According to the results of sample analysis, the yield of uranium in the bench test is >99.98%. The plutonium purification coefficients in the 2D tanks of the two bench tests are both greater than 1000, and the plutonium content in the 2EU feed solution is 10. -10 g / g uranium.

Embodiment 2

[0016] The operation is as in Example 1, the difference is that the composition of 2DS detergent is 0.01mol / L DMHAN-0.05mol / L MMH-1.2mol / L HNO 3 , the purification factor of plutonium is greater than 800.

[0017] Example 2

[0018] The operation is as in Example 1, the difference is that the composition of 2DS detergent is 0.1mol / L DMHAN-0.15mol / L MMH-0.8mol / L HNO 3 , the purification factor of plutonium is greater than 950.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com