Marble ceramic tile surface treatment method

A technology for surface treatment and marble, applied in the field of surface treatment of marble tiles, can solve the problems of difficult to clean oil stains on tiles, single product color sample, easy to breed bacteria, etc., achieve a simple surface treatment method, do not affect the environment, and improve product competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

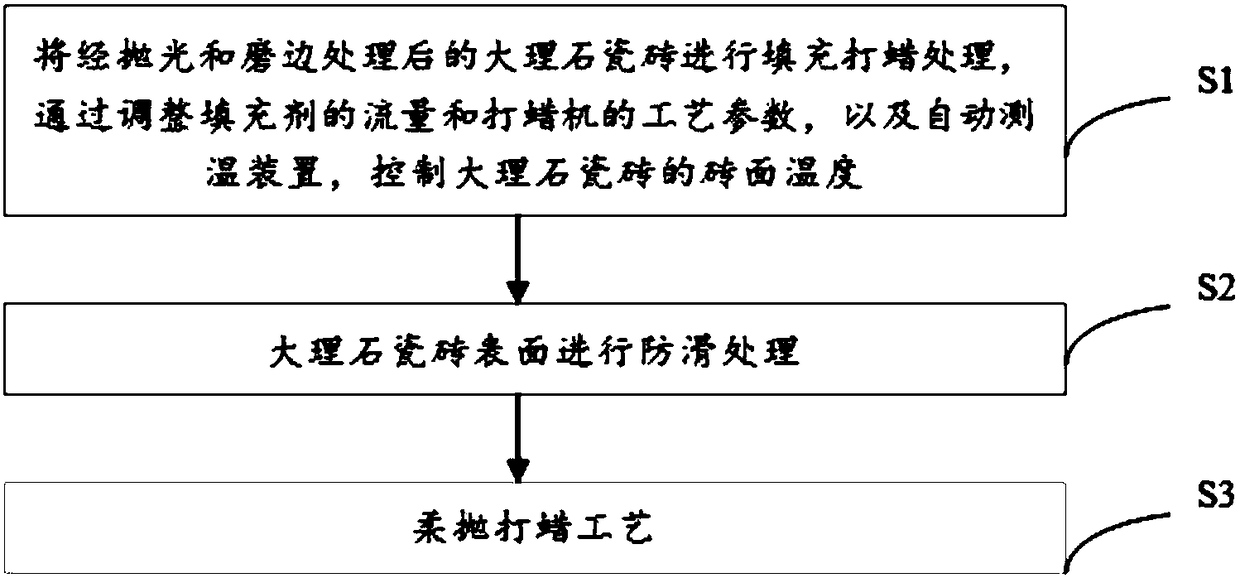

[0022] see figure 1 , is the flow chart of the surface treatment process of marble tiles provided in this embodiment. The process includes steps:

[0023] S1: Fill and wax the marble tiles after polishing and edging, and control the surface temperature of the marble tiles by adjusting the flow rate of the filler, the process parameters of the waxing machine, and the automatic temperature measuring device.

[0024] This step is used for filling and waxing treatment. In this step, the marble tiles are polished and edged to a smooth surface, and the marble tiles include polished tiles with a porcelain surface or polished tiles with an enamelled surface

[0025] In this step, the filler is nano-silica sol, and the micropores on the surface of the marble tiles are filled with the filler.

[0026] In this step, the process parameters of the waxing machine mainly include the number of grinding heads, the abrasive material and the pressure of the waxing machine. The automatic tempe...

Embodiment 2

[0035] This embodiment provides a surface treatment process for marble tiles. The difference between this process and Example 1 is that in step S1, the waxing machine uses 7 groups of grinding heads, the abrasive is medium-hard abrasive, and the waxing pressure is 15 MPa. The brick surface temperature displayed by the infrared automatic thermometer is between 66°C; in step S3, the waxing machine uses 5 sets of grinding heads, the abrasive is soft abrasive, and the waxing pressure is 7MPa.

[0036] The product produced by the surface treatment process of marble tiles provided in this embodiment has a coefficient of sliding friction of 0.72 and a glossiness of 63 degrees. The antifouling grade is 5 according to the provisions of GB / T3810.14, and the excellent polishing rate of the product is 98.2%, and the texture, color, transparency, texture and other properties of the marble tile have no obvious changes.

Embodiment 3

[0038] This embodiment provides a surface treatment process for marble tiles. The difference between this process and Example 1 is that in step S1, the waxing machine uses 9 groups of grinding heads, the abrasive is hard abrasive, and the waxing pressure is 17MPa. The brick surface temperature displayed by the automatic thermometer is 80°C; in step S3, the waxing machine uses 3 sets of grinding heads, the abrasive is soft abrasive, and the waxing pressure is 8MPa.

[0039] The product produced by the surface treatment process of marble tiles provided in this embodiment has a coefficient of sliding friction of 0.79 and a glossiness of 56 degrees. The antifouling grade of the inspection according to the provisions of GB / T3810.14 is 5 grades, and the excellent rate of product polishing is 99.3%, and the texture, color, transparency, texture and other properties of the marble tiles have no obvious changes, and the surface treatment process of this embodiment is the best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com