Surface treatment method for aluminum alloy die casting and product thereof

A technology of surface treatment and surface treatment agent, which is applied in the direction of surface coating liquid device, metal material coating process, liquid chemical plating, etc. Anode dyeing, magnesium alloy chemical properties live wave and other problems, to achieve the effect of simple surface treatment method, dense alloy layer and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

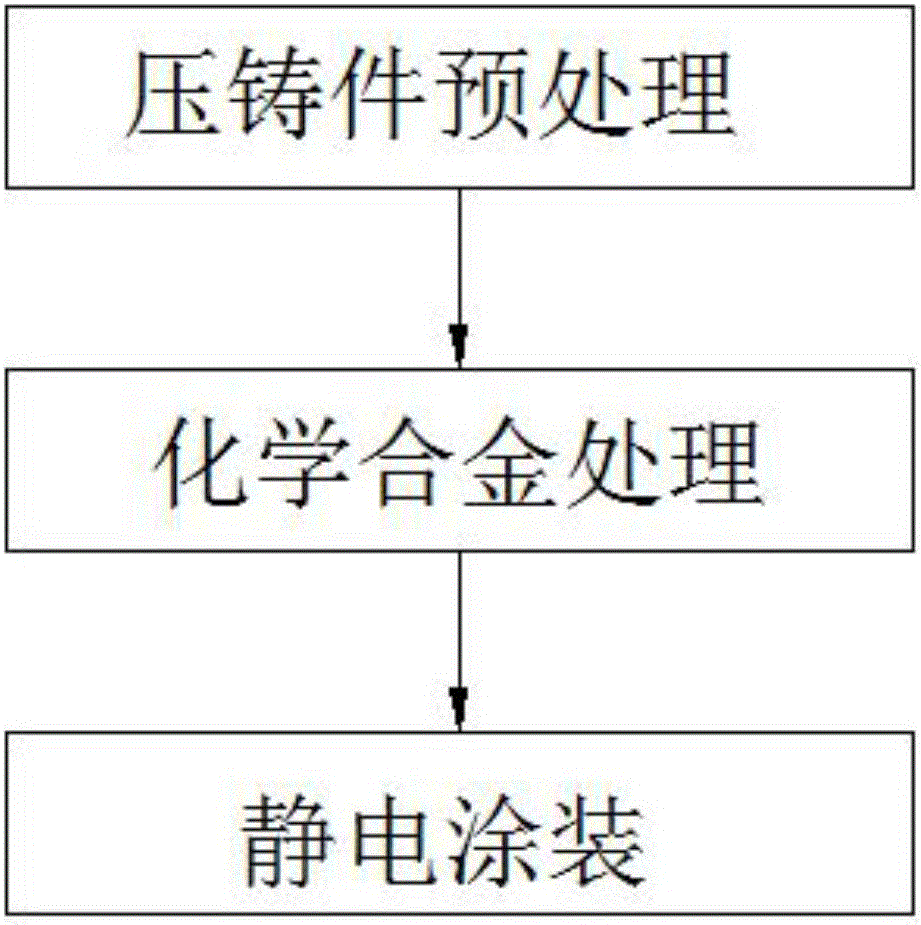

[0027] A method for surface treatment of an aluminum alloy die casting, comprising the steps of:

[0028] S1. Pretreatment of die castings:

[0029] a. Shot blasting treatment: Use stainless steel projectiles with a size of 0.25-0.4mm at a projectile speed of 55m / s to perform shot blasting treatment on the die-casting parts to remove the oxide skin on the surface of the die-casting parts; It is ultrasonically cleaned;

[0030] b. Wax removal: Dip the die-casting parts with descaled surface into 10 parts of triethanolamine oleic acid soap, 3 parts of polyacrylamide, 0.5 parts of coconut oleic acid diethanolamide, 5 parts of tetrasodium edetate, iso 1 part of glycidyl caprylic acid, 6 parts of borosilicate, 2 parts of Tween, 6 parts of trimethyl metasilicate, and 0.5 parts of sodium citrate in a wax remover solution to remove surface wax;

[0031] c. Degreasing: Soak the above-mentioned die-casting parts after dewaxing in alkaline cleaning agent for 30 minutes to remove surfac...

Embodiment 2

[0037] A method for surface treatment of an aluminum alloy die casting, comprising the steps of:

[0038] S1. Pretreatment of die castings:

[0039] a. Shot blasting treatment: Use stainless steel projectiles with a size of 0.25-0.4mm, at a projectile speed of 60m / s, to perform shot blasting treatment on the die-casting parts to remove the oxide skin on the surface of the die-casting parts; after the shot blasting, use ultrasonic equipment to It is ultrasonically cleaned;

[0040] b. Wax removal: Dip the die-casting parts with descaled surfaces into 12 parts of triethanolamine oleic acid soap, 2 parts of polyacrylamide, 2.5 parts of coconut oleic acid diethanolamide, 4 parts of tetrasodium edetate, iso 1 part of glycidyl caprylic acid, 6 parts of borosilicate, 3 parts of Tween, 4 parts of trimethyl metasilicate, and 1 part of sodium citrate in a wax remover solution to remove surface wax;

[0041] c. Degreasing: Soak the above-mentioned die-casting parts after dewaxing in al...

Embodiment 3

[0047] A method for surface treatment of an aluminum alloy die casting, comprising the steps of:

[0048] S1. Pretreatment of die castings:

[0049] a. Shot blasting treatment: Use stainless steel projectiles with a size of 0.25-0.4mm at a projectile speed of 55m / s to perform shot blasting treatment on the die-casting parts to remove the oxide skin on the surface of the die-casting parts; It is ultrasonically cleaned;

[0050]b. Waxing removal: Dip the die-casting parts with descaled surfaces into 15 parts of triethanolamine oleic acid soap, 1 part of polyacrylamide, 4 parts of coconut oleic acid diethanolamide, 3 parts of tetrasodium edetate, iso 2 parts of glycidyl caprylic acid, 5 parts of borosilicate, 6 parts of Tween, 1 part of trimethyl metasilicate, and 2.5 parts of sodium citrate in a wax remover solution to remove surface wax;

[0051] c. Degreasing: Soak the above-mentioned die-casting parts after wax removal in alkaline cleaning agent for 15 minutes to remove sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com