Polyester tangential belt with long service life, and manufacturing method thereof

A technology of polyester dragon belt and longevity, applied in the direction of chemical instruments and methods, applications, belts, etc., can solve the problems of high hardness, unusable, broken, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

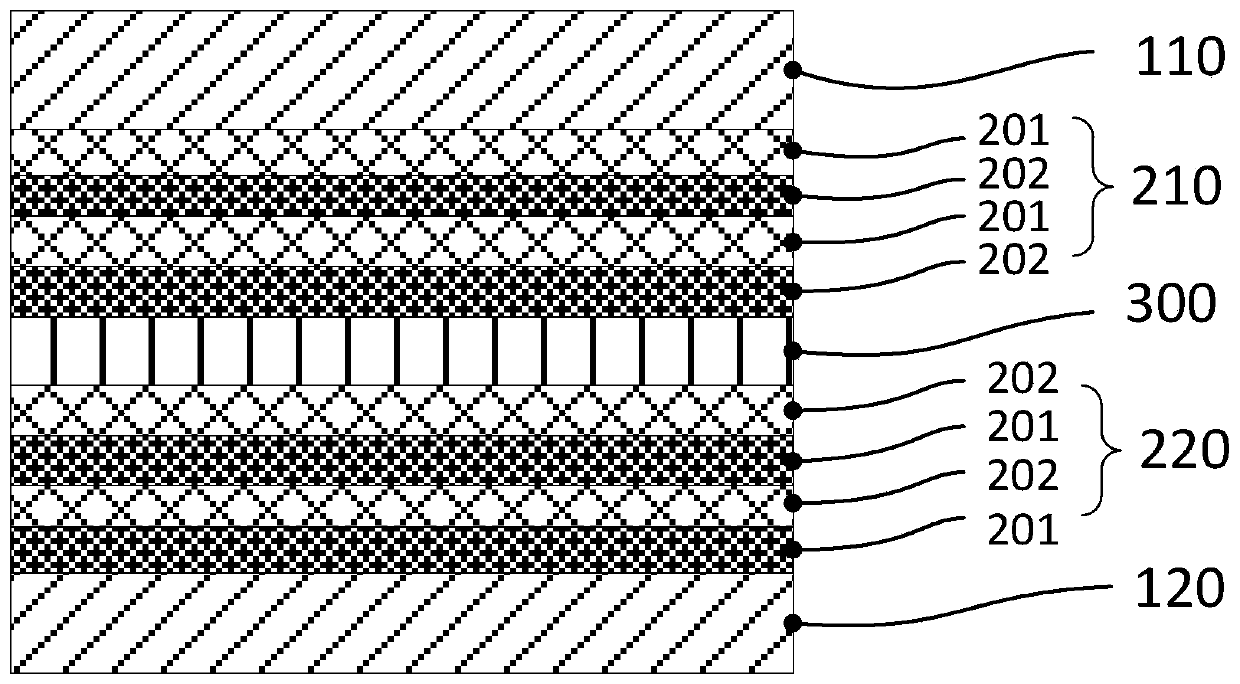

[0056] like figure 1 As shown, a new polyester dragon belt is as follows from top to bottom: upper rubber transmission layer 110, upper buffer layer 210, skeleton layer 300, upper buffer layer 220, lower rubber friction layer 120, and the upper buffer layer 210 is from From top to bottom are the first elastomer layer 201, the second elastomer layer 202, the first elastomer layer 201, and the second elastomer layer 202. The first elastomer layer 201 is TPU with a hardness of 95A and a thickness of 0.2mm. Sheet layer, the second elastomer layer 202 is a TPU sheet layer with a hardness of 85A and a thickness of 0.1mm; the lower buffer layer is the second elastomer layer 202, the first elastomer layer 201, The second elastomer layer 202, the first elastomer layer 201, the first elastomer layer 201 is a TPU sheet layer with a hardness of 95A and a thickness of 0.2mm, and the second elastomer layer 202 is a hardness of 85A and a thickness of 0.1mm The TPU sheet layer; the skeleton ...

Embodiment 2

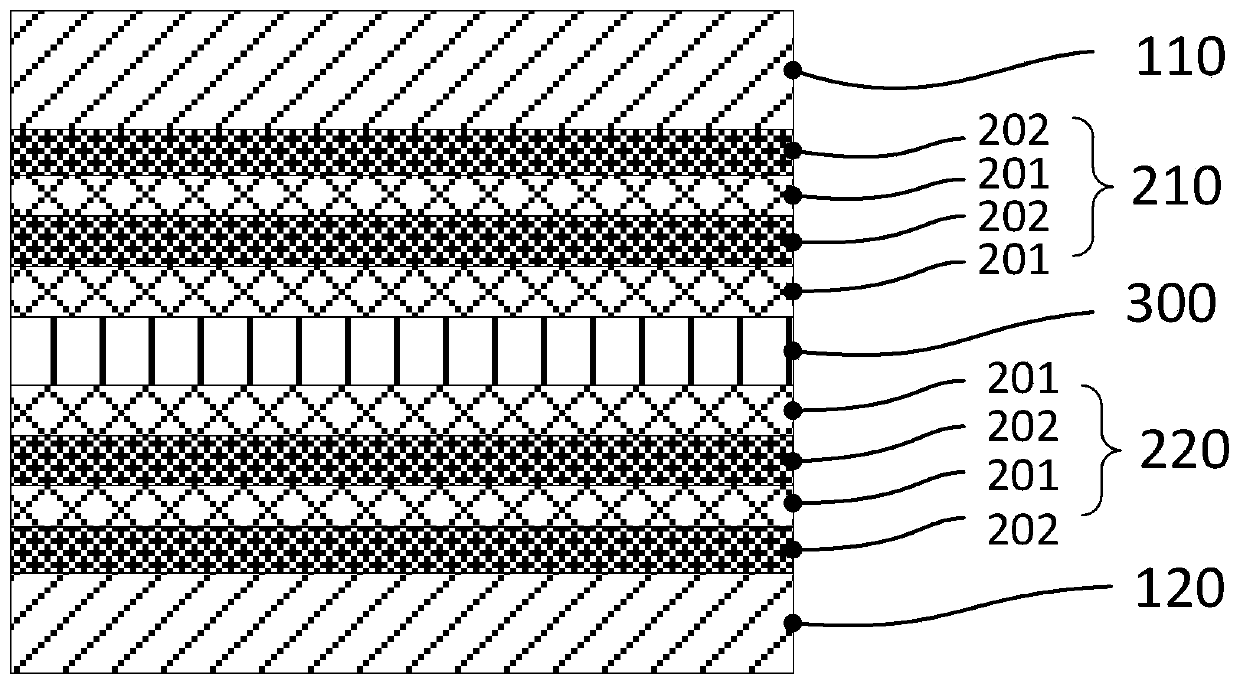

[0087] like figure 2 As shown, the new polyester dragon belt in this embodiment is from top to bottom: the upper rubber transmission layer 110, the upper buffer layer 210, the skeleton layer 300, the lower buffer layer 220, the lower rubber friction layer 120, the upper buffer layer From top to bottom are the second elastomer layer 202, the first elastomer layer 201, the second elastomer layer 202, and the first elastomer layer 201. The first elastomer layer 201 has a hardness of 95A and a thickness of 0.25mm. TPU sheet layer, the second elastomer layer 202 is a TPU sheet layer with a hardness of 85A and a thickness of 0.05mm; the lower buffer layer is sequentially the first elastomer layer 201 and the second elastomer layer 202 from top to bottom , the first elastomer layer 201, the second elastomer layer 202, the first elastomer layer 201 is a TPU sheet layer with a hardness of 95A and a thickness of 0.25mm, and the second elastomer layer 202 is a hardness of 85A and a thic...

Embodiment 3

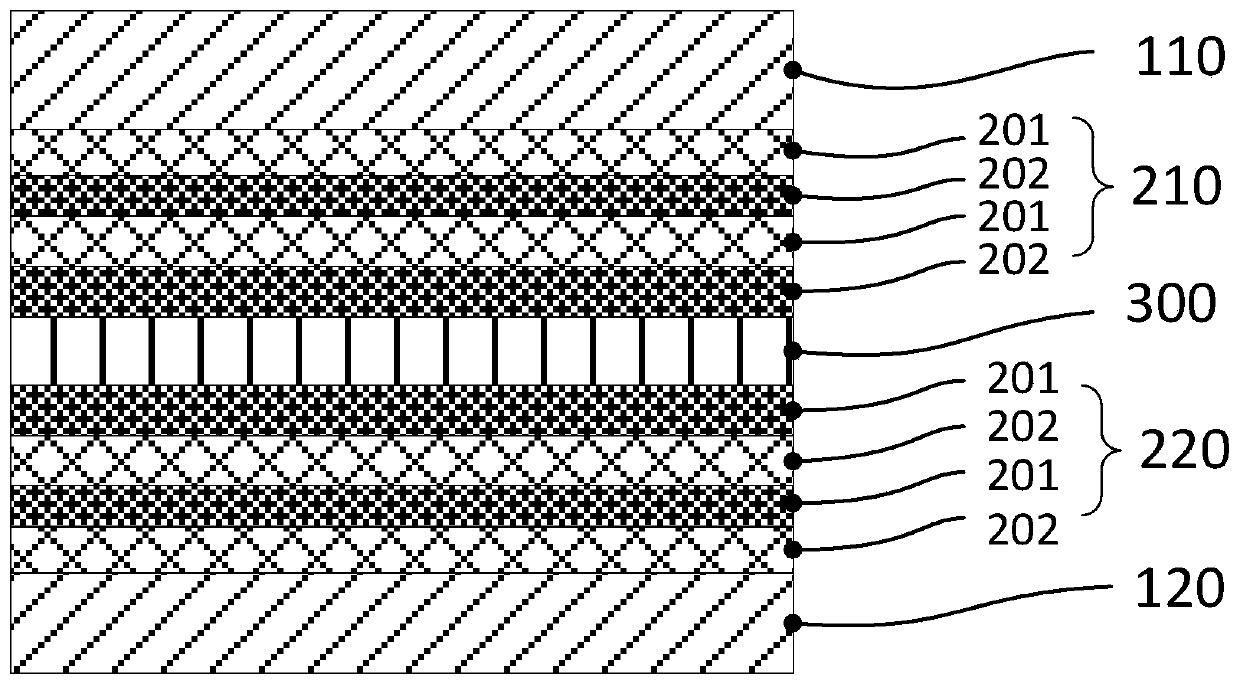

[0090] like image 3 As shown, a new polyester dragon belt is as follows from top to bottom: upper rubber transmission layer 110, upper buffer layer 210, skeleton layer 300, upper buffer layer 220, lower rubber friction layer 120, and the upper buffer layer is from the top From bottom to bottom are the first elastomer layer 201, the second elastomer layer 202, the first elastomer layer 201, and the second elastomer layer 202. The first elastomer layer 201 is a TPU sheet with a hardness of 95A and a thickness of 0.25 mm. Material layer, the second elastomer layer 202 is a TPU sheet layer with a hardness of 85A and a thickness of 0.15mm; the lower buffer layer is the first elastomer layer 201, the second elastomer layer 202, the An elastomer layer 201 and a second elastomer layer 202, the first elastomer layer 201 is a TPU sheet layer with a hardness of 95A and a thickness of 0.25mm, and the second elastomer layer 202 is a TPU sheet layer with a hardness of 85A and a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com