Preparation method of conductive sponge

A technology of conductive sponge and sponge, which is applied in the field of sponge conduction, and can solve the problems of small resistance of conductive sponge and large resistance of conductive sponge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

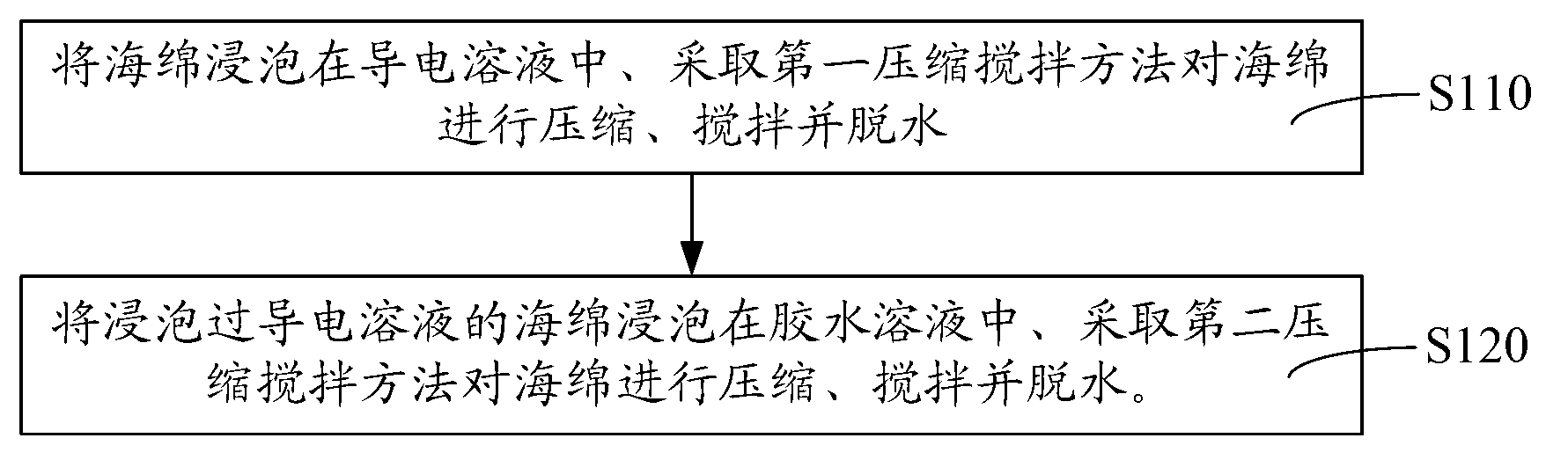

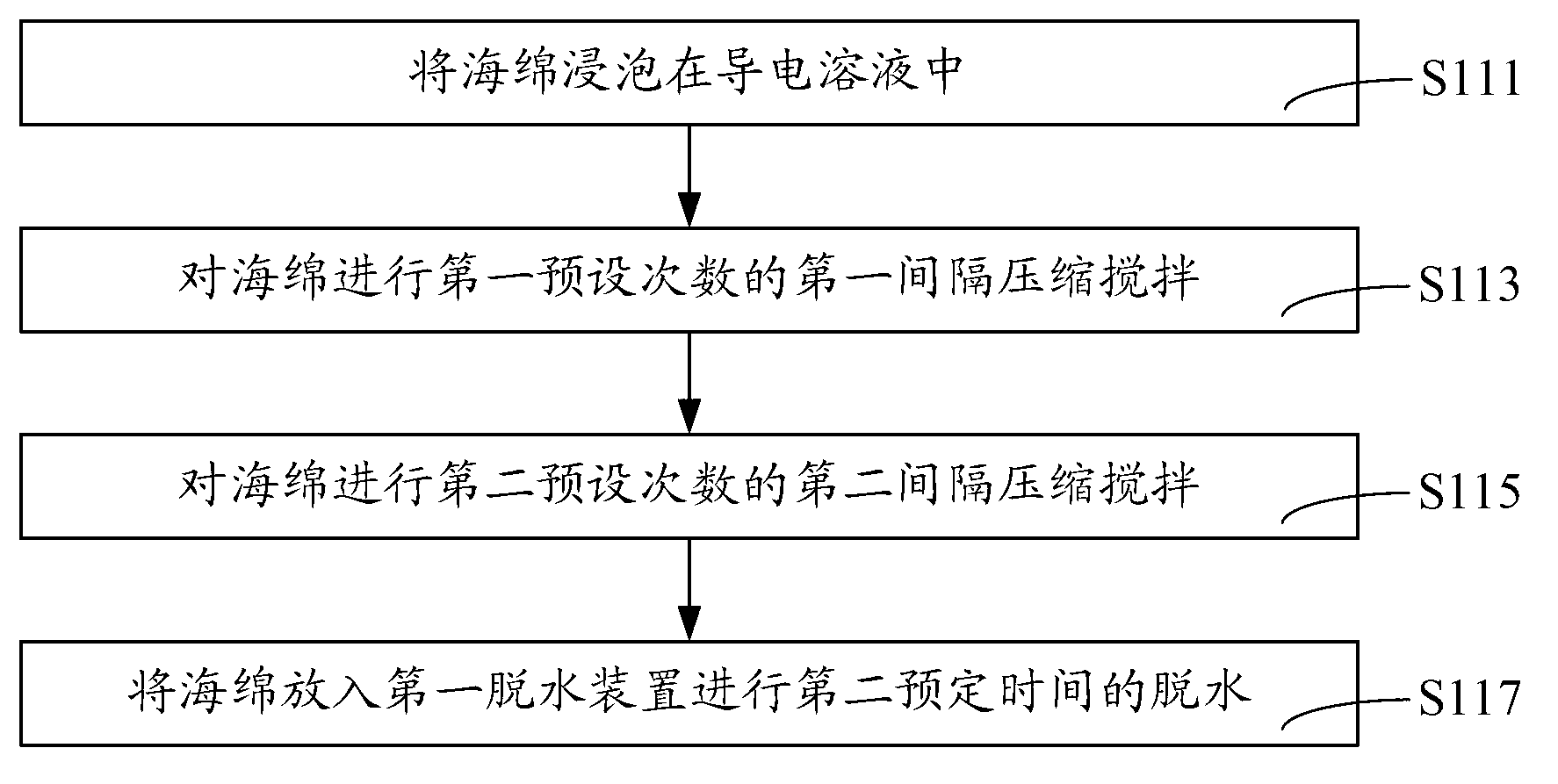

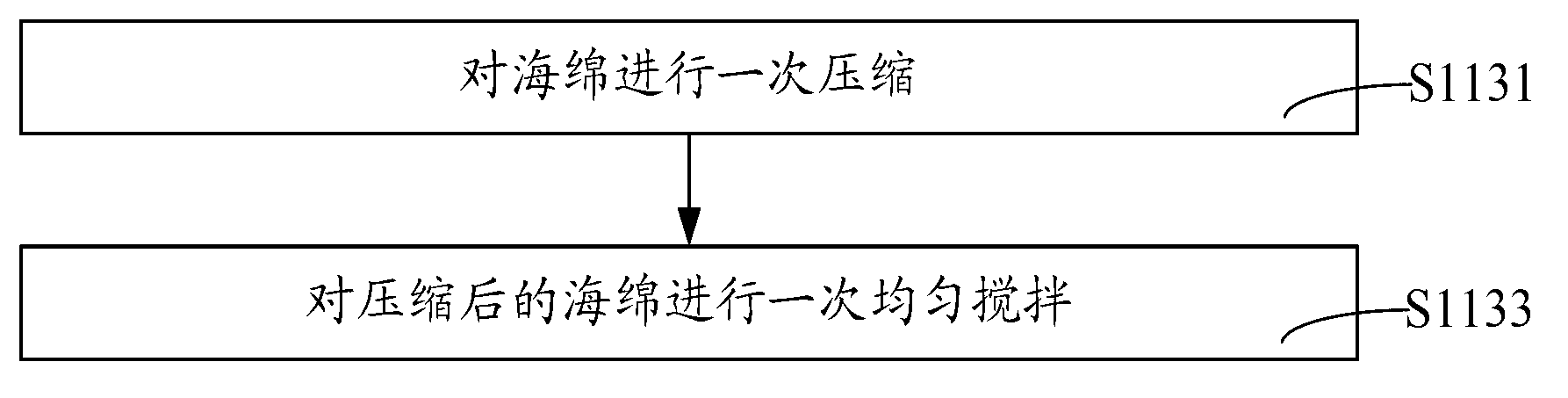

[0030] The invention discloses a preparation method of a conductive sponge. In the preparation process of the conductive sponge, the sponge is respectively soaked in a conductive solution and a glue solution, and treated with different treatment methods, including compressing and stirring the sponge soaked in the solution respectively. Adopting the above-mentioned preparation method can make the sponge better absorb the conductive particles, and the conductive particles and the sponge can be better adhered to by the glue particles, so that the surface resistance of the conductive sponge is smaller, the volume resistance distribution is more uniform, and the prepared conductive sponge is processed. The subsequent hardness changes are smaller.

[0031] The preparation method of a conductive sponge of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0032] figure 1 , is a flow chart of the preparation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com