Cold-resistant non-slip rubber sports shoe material and manufacturing method thereof

A rubber and anti-slip technology, which is applied in the manufacture of cold-resistant anti-slip rubber sports shoe materials and cold-resistant anti-slip rubber sports shoe materials, to achieve the effect of ensuring comfort and safety and improving comfort

Inactive Publication Date: 2015-09-09

XIAMEN MAITU NEW MATERIAL CO LTD

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the relevant research reports and patent documents on cold-resistant anti-slip rubber shoe materials have not yet appeared in the newspapers.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

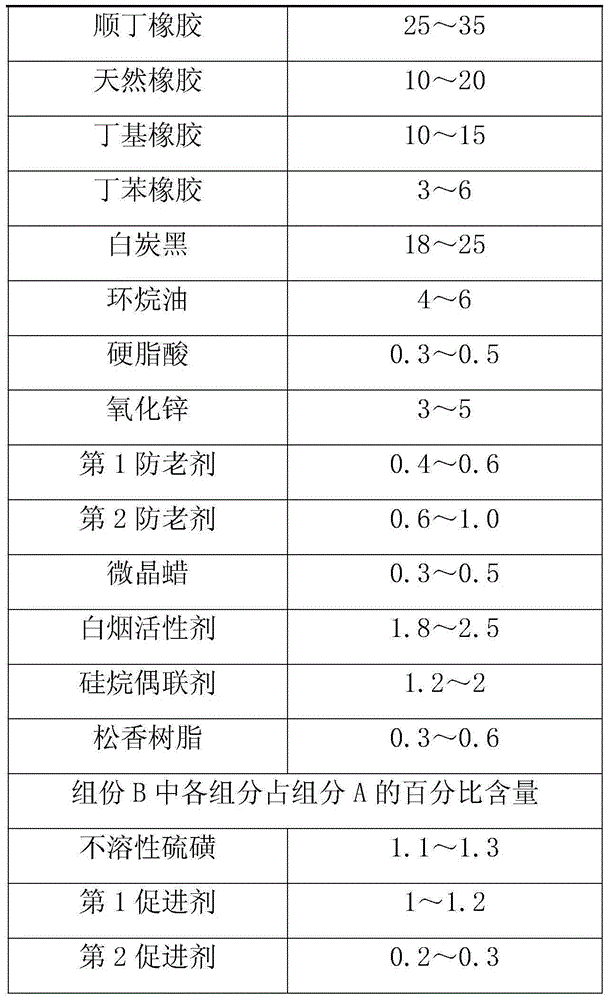

[0037] In order to better understand the present invention, the following examples will further illustrate the present invention in detail, but it should not be construed as a limitation to the present invention. For those skilled in the art, some non-essential improvements and adjustments made based on the above-mentioned content of the invention, It is also deemed to fall within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

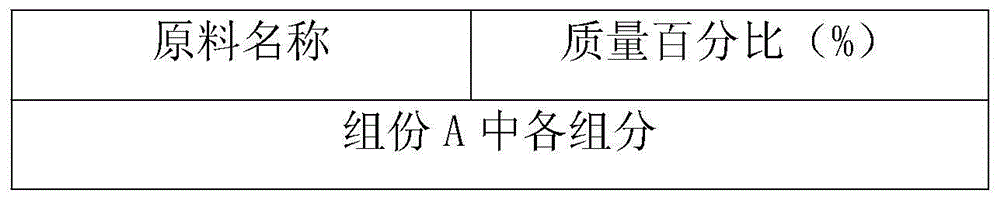

The invention discloses a cold-resistant non-slip rubber sports shoe material and a manufacturing method thereof. The cold-resistant non-slip rubber sports shoe material is made of raw materials comprising a composite A and a composite B, the composite A includes butadiene rubber, natural rubber, butyl rubber, butadiene styrene rubber, white carbon black, naphthenic oil, stearic acid, zinc oxide, a first antiager, a second antiager, microcrystalline wax, a white smoke surfactant, a silane coupling agent and rosin resin; the composite B includes insoluble sulfur, a first accelerator and a second accelerator. The invention further discloses a manufacturing method of the cold-resistant non-slip rubber sports shoe material. The method includes the steps of material weighing, closed mixing, open mixing, dosing, vulcanization curve measuring and hydraulic molding. The cold-resistant non-slip rubber sports shoe material has cold-resistance, weather-proof and non-slip performances.

Description

Technical field [0001] The invention relates to a shoe material, in particular to a cold-resistant anti-slip rubber sports shoe material. The invention also relates to a method for manufacturing a cold-resistant anti-slip rubber sports shoe material. Background technique [0002] Functional shoe materials have been a strategic demand of major sports brands in recent years. Sports brands have experienced an era when they only value appearance and structure while ignoring functions. With the prosperity of Chinese people’s lives, there is a need for product performance, comfort, and functionality. Pursuit, a pair of sports shoes without outstanding features, just like a soulless person, there is no selling point, there is no capital to attract consumers' attention. [0003] Cold-resistant and anti-slip rubber shoe materials are a topic that people often pay attention to in recent years, and it is also a new member of the functional shoe material family that has developed to today. In...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L9/00C08L7/00C08L23/22C08L9/06C08K13/02C08K3/36C08K3/22C08K5/09C08K3/06C08K5/13

CPCC08L9/00A43B1/10C08L2205/02C08L2205/035C08L7/00C08L23/22C08L9/06C08L91/00C08L91/06C08L93/04C08L71/02C08K13/02C08K3/36C08K2003/2296C08K5/09C08K3/06C08K5/13

Inventor 李阳黄宝勇

Owner XIAMEN MAITU NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com