High-temperature-resistant abrasion-resistant macromolecule shock-absorption rubber for vehicles, preparation method of high-temperature-resistant abrasion-resistant macromolecule shock-absorption rubber, and preparation method of automobile exhaust pipe lug

A shock-absorbing rubber and high-temperature-resistant technology, which is applied in the field of automobile shock absorption, can solve the problems of reduced overall performance of exhaust pipe lifting lugs, wear and damage of installation points, and increased hardness of rubber body, so as to shorten vulcanization time, prevent pollution, The effect of reducing the tendency to scorch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

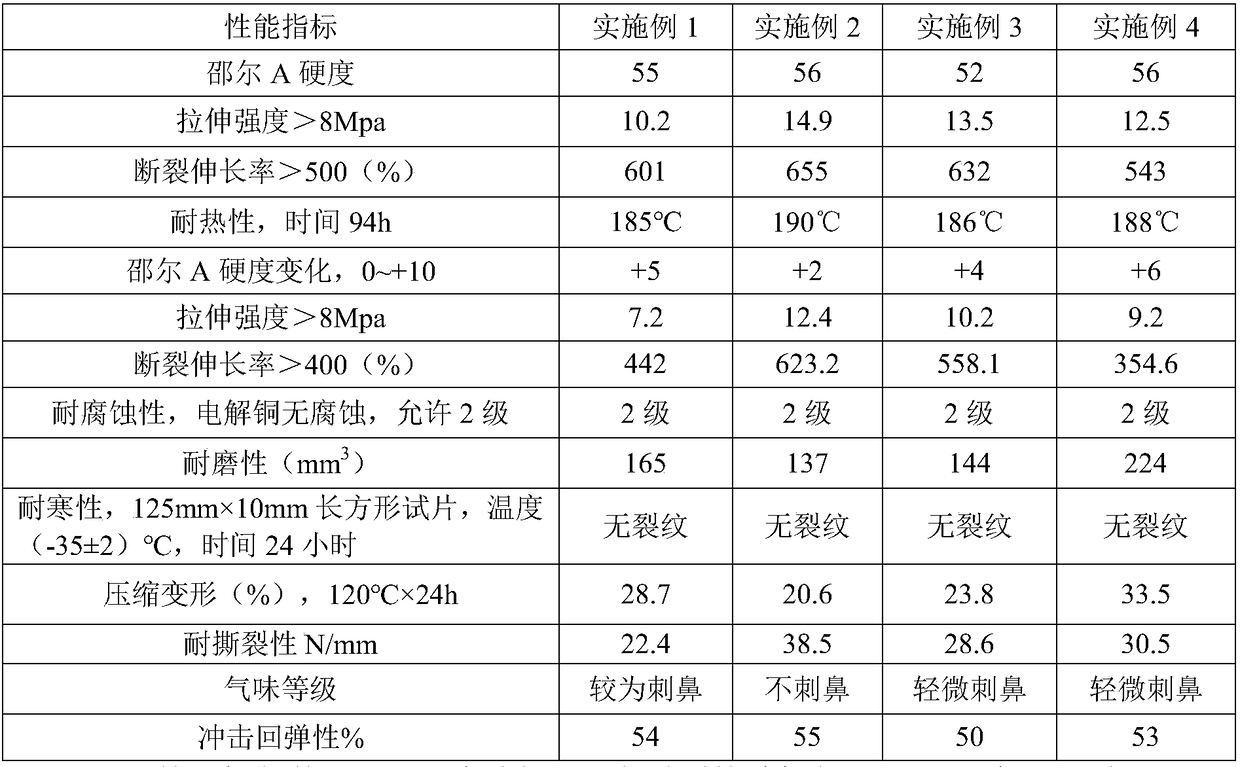

Examples

Embodiment 1

[0046] Step 1. Send 70 parts of EPDM rubber and 30 parts of silica gel into the mixing tank of the banburying equipment according to the mass parts. The speed of the banbury mixer is 28rmp, the pressure hammer pressure is 0.7MPa, the pressure hammer temperature is 75°C, and fully stirred and mixed for 1min ;

[0047] Step 2. Add 5 parts of zinc oxide, 1 part of stearic acid, 0.1 part of essence, 5 parts of NM001 wear-resistant agent, 1 part of microcrystalline wax 654, 1 part of anti-aging agent Naugard445, 4 parts of general flow dispersant RL12 and 1 part of ancient Malone resin, stirring and mixing for 1-3 minutes, plasticizing for 50 seconds;

[0048] Step 3. Add 30 parts of carbon black N550, 60 parts of carbon black N330 and 2 parts of paraffin oil 2280, fully stir and mix for 5 minutes, and banbury and heat up at the same time;

[0049] Step 4. After the banburying temperature rises to 115°C, the rubber is discharged to the refining equipment, and the refining is carri...

Embodiment 2

[0052] Step 1. Send 70 parts of EPDM rubber and 30 parts of silica gel into the mixing tank of the banburying equipment according to the mass parts. The speed of the banbury mixer is 30rmp, the pressure hammer pressure is 0.6MPa, the pressure hammer temperature is 80°C, and fully stirred and mixed for 2 minutes ;

[0053] Step 2. Add 15 parts of zinc oxide, 2 parts of stearic acid, 0.3 parts of essence, 5 parts of NM001 wear-resistant agent, 2 parts of microcrystalline wax 654, 0.5 parts of antioxidant MB, 2 parts of universal flow dispersant RL12 and 3 parts of ancient Malone resin, stir and mix for 1-3min, plasticize for 60s;

[0054] Step 3. Add 45 parts of carbon black N550, 25 parts of carbon black N330 and 2 parts of paraffin oil 2280, fully stir and mix for 6 minutes, and banbury and heat up at the same time;

[0055] Step 4. After the banburying temperature rises to 120°C, the glue is discharged to the opening milling equipment, and the refining is carried out. Finall...

Embodiment 3

[0058] Step 1. Send 60 parts of EPDM rubber and 40 parts of silica gel into the mixing tank of the banburying equipment according to the mass parts, the speed of the banbury mixer is 30rmp, the pressure hammer pressure is 0.7MPa, the pressure hammer temperature is 80°C, and fully stirred and mixed for 3min ;

[0059] Step 2. Add 15 parts of zinc oxide, 2 parts of SA stearic acid, 0.3 parts of essence, 8 parts of anti-aging agent, 0.6 parts of anti-aging agent MB, 3 parts of general flow dispersant RL12, 3 parts of microcrystalline wax and 5 parts of Guma Long resin, stirring and mixing for 3 minutes;

[0060] Step 2. Add 15 parts of zinc oxide, 2 parts of stearic acid, 0.3 parts of essence, 8 parts of NM001 wear-resistant agent, 3 parts of microcrystalline wax 654, 0.6 parts of anti-aging agent, 3 parts of universal flow dispersant RL12 and 5 parts of Guma Long resin, stirring and mixing for 1-3min, plasticizing for 65s;

[0061] Step 3. Add 40 parts of carbon black N550, 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com