Preparation and application of macromolecular silane coupling agent used for ethylene propylene diene monomer rubber

A technology of molecular silane coupling agent and EPDM rubber, which is applied in the field of functional polymer materials, can solve the problems of few effective groups and unsatisfactory modification effect, so as to improve mechanical properties and interface compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

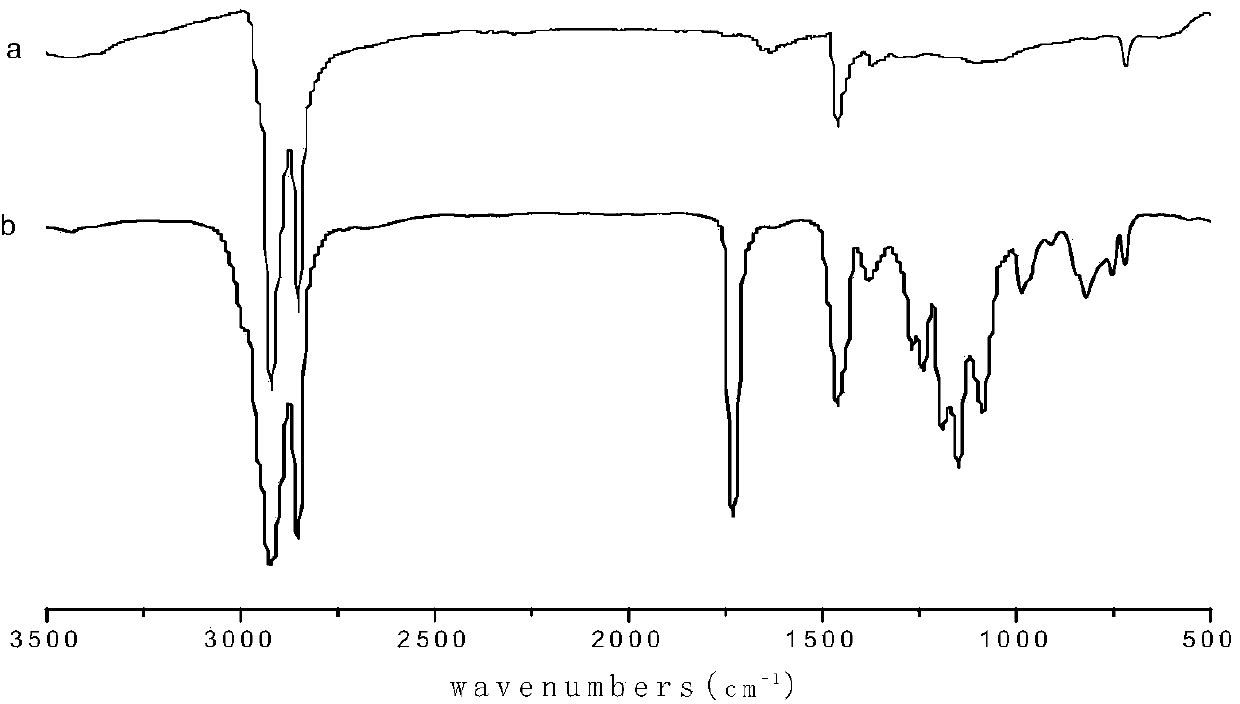

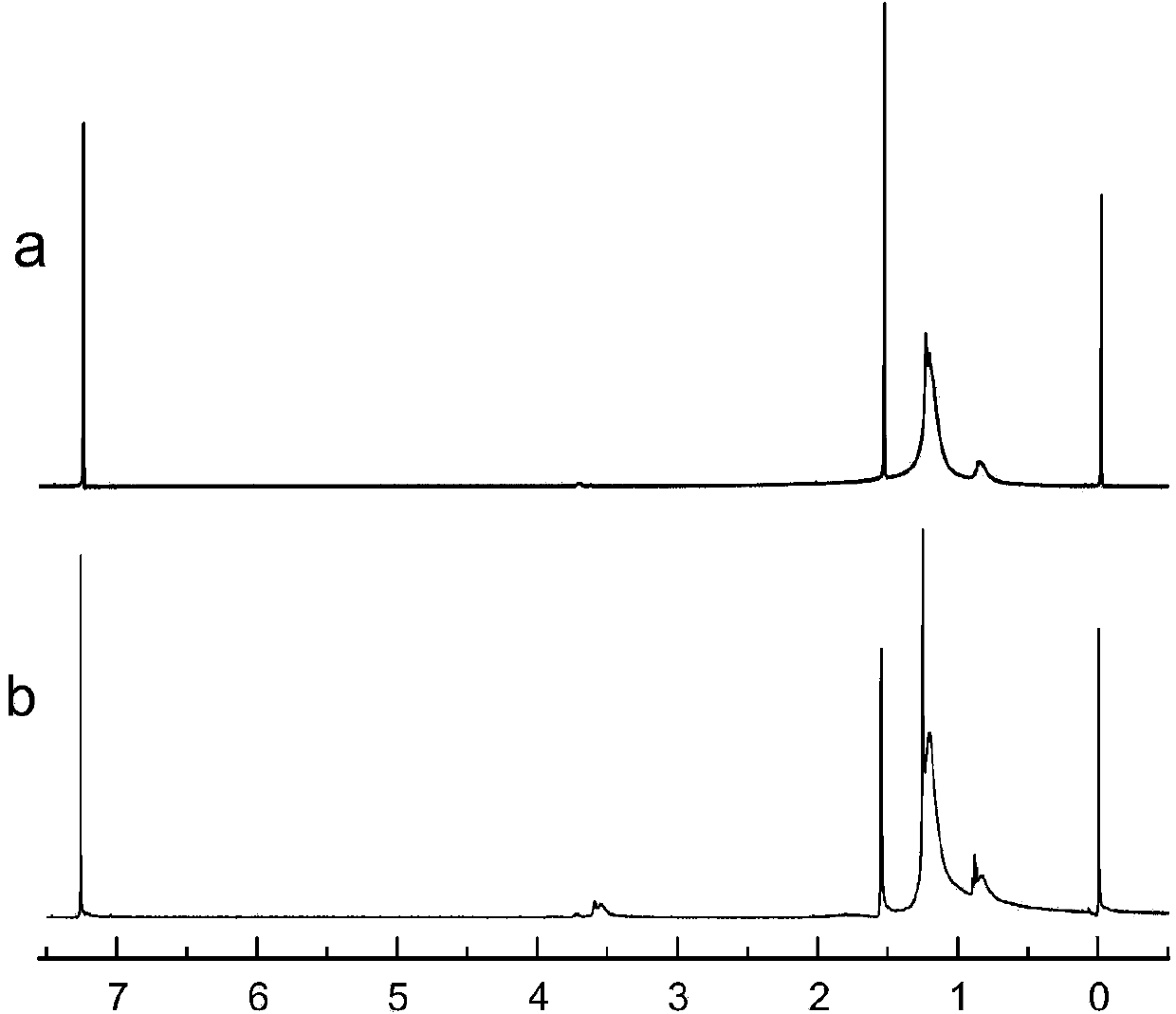

Image

Examples

Embodiment 1

[0021] Dissolve 8g of EPDM in 100ml of toluene and add it to a dry four-necked flask, then add 3.75g of methyl methacrylate and 2.5g of γ-methacryloxypropyl trimethoxysilane. Stirring was continued at 90°C, and nitrogen gas was bubbled for 30 minutes to obtain a mixed system of reactants;

[0022] Then the initiator benzoyl peroxide of 0.1425g is dissolved in the toluene of 30ml and stirs, slowly be added dropwise in the above-mentioned reactant mixed system (continuous stirring reactant mixed system in the process of dropping, and the reactant mixed system The temperature was kept at 90°C), and the time of dropping was controlled at 30min. After the dropwise addition was completed, stirring was continued at 90°C for 16 hours. After the reaction was completed, it was cooled to room temperature, precipitated with excess methanol, filtered, and obtained Crude product of molecular silane coupling agent.

[0023] The macromolecular silane coupling agent crude product obtained abo...

specific Embodiment 2-5

[0033] The differences between the synthesis process conditions of the macromolecular coupling agent and Example 1 are shown in Table 2, and the rest of the preparation process is the same as that of Example 1. The process for surface-treating silica with the macromolecular coupling agent is the same as in Example 1, and the preparation process for the surface-treated silica-filled EPDM composite material is the same as in Example 1. The resulting mechanical properties are shown in Table 3

[0034] Table 2

[0035]

[0036] table 3

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com