Hydraulic-controlled clutch pipe and production process thereof

A production process and clutch technology, applied in the direction of hoses, pipes, tubular objects, etc., can solve the problems of poor high temperature resistance and pulse performance, high elongation of polyester fiber, poor heat resistance, etc., and improve heat aging resistance. , Good resistance to engine oil and high temperature heat aging, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

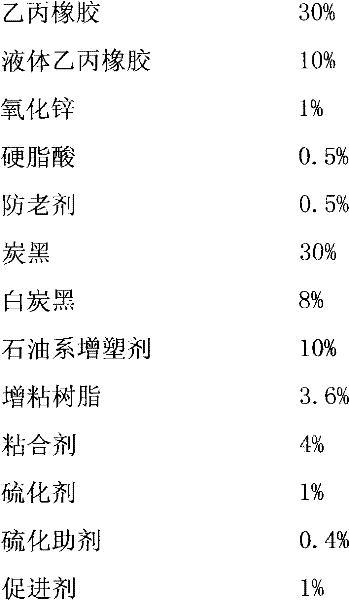

[0055] The inner rubber layer is made of the following materials by weight:

[0056]

[0057] The cover is made from the following ingredients by weight:

[0058]

[0059] (1) Inner rubber mixing and extrusion: first put ethylene propylene rubber, zinc oxide, stearic acid, tackifying resin, and anti-aging agent into the mixing room for pressurized mixing, then carbon black N330, carbon black N550, white Carbon black and petroleum-based plasticizers are added, the pressure is 0.5MPa during banburying, when the temperature rises to 90°C, depressurize once, when the temperature rises to 100°C, depressurize once, when the temperature rises to 130°C, lift the top The bolt is discharged, the lower strip is cooled, and then the second-stage banburying is carried out. Add a section of banbury rubber, adhesives, vulcanizing agents, vulcanization aids and accelerators into the banburying room for pressurized banburying. When the temperature reaches 90°C , lift the top bolt to rem...

Embodiment 2

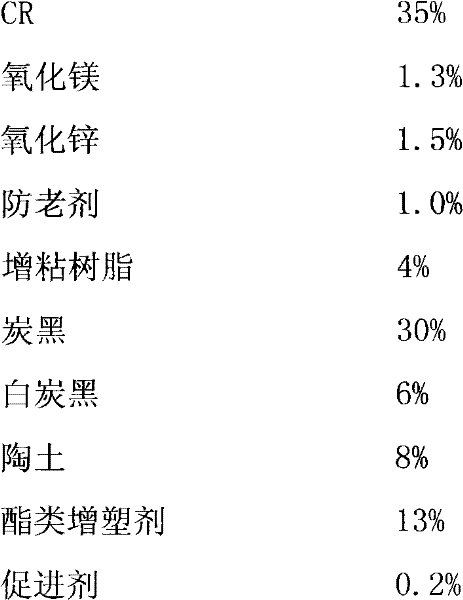

[0063] The inner rubber layer is made of the following materials by weight:

[0064]

[0065]

[0066] The cover is made from the following ingredients by weight:

[0067]

[0068] (1) Inner rubber mixing and extrusion: first put ethylene propylene rubber, zinc oxide, stearic acid, tackifying resin, and anti-aging agent into the mixing room for pressurized mixing, then carbon black N330, carbon black N550, white Carbon black and petroleum-based plasticizers are added, the pressure is 0.5MPa during banburying, when the temperature rises to 90°C, depressurize once, when the temperature rises to 100°C, depressurize once, when the temperature rises to 130°C, lift the top The bolt is discharged, the lower strip is cooled, and then the second-stage banburying is carried out. Add a section of banbury rubber, adhesives, vulcanizing agents, vulcanization aids and accelerators into the banburying room for pressurized banburying. When the temperature reaches 90°C , lift the top...

Embodiment 3

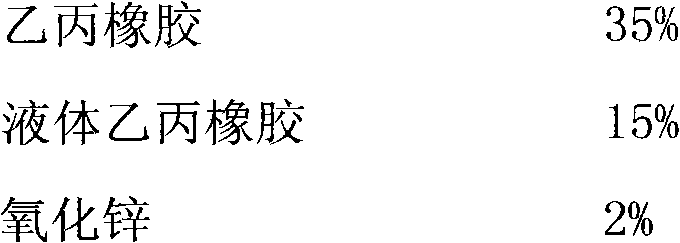

[0072] The inner rubber layer is made of the following materials by weight:

[0073]

[0074] The cover is made from the following ingredients by weight:

[0075]

[0076]

[0077] (1) Inner rubber mixing and extrusion: first put ethylene propylene rubber, zinc oxide, stearic acid, tackifying resin, and anti-aging agent into the mixing room for pressurized mixing, then carbon black N330, carbon black N550, white Carbon black and petroleum-based plasticizers are added, the pressure is 0.5MPa during banburying, when the temperature rises to 90°C, depressurize once, when the temperature rises to 100°C, depressurize once, when the temperature rises to 130°C, lift the top The bolt is discharged, the lower strip is cooled, and then the second-stage banburying is carried out. Add a section of banbury rubber, adhesives, vulcanizing agents, vulcanization aids and accelerators into the banburying room for pressurized banburying. When the temperature reaches 90°C , lift the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com