Test apparatus for ultraviolet aging acceleration of asphalt-based materials

A test device and asphalt-based technology, which is applied to measurement devices, analytical materials, instruments, etc., can solve the problems of inability to accurately quantitatively analyze ultraviolet radiation energy, cumbersome operation steps for asphalt specimens, and uneven aging of specimens. To adjust the work, the structure is simple, the effect of uniform light aging degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

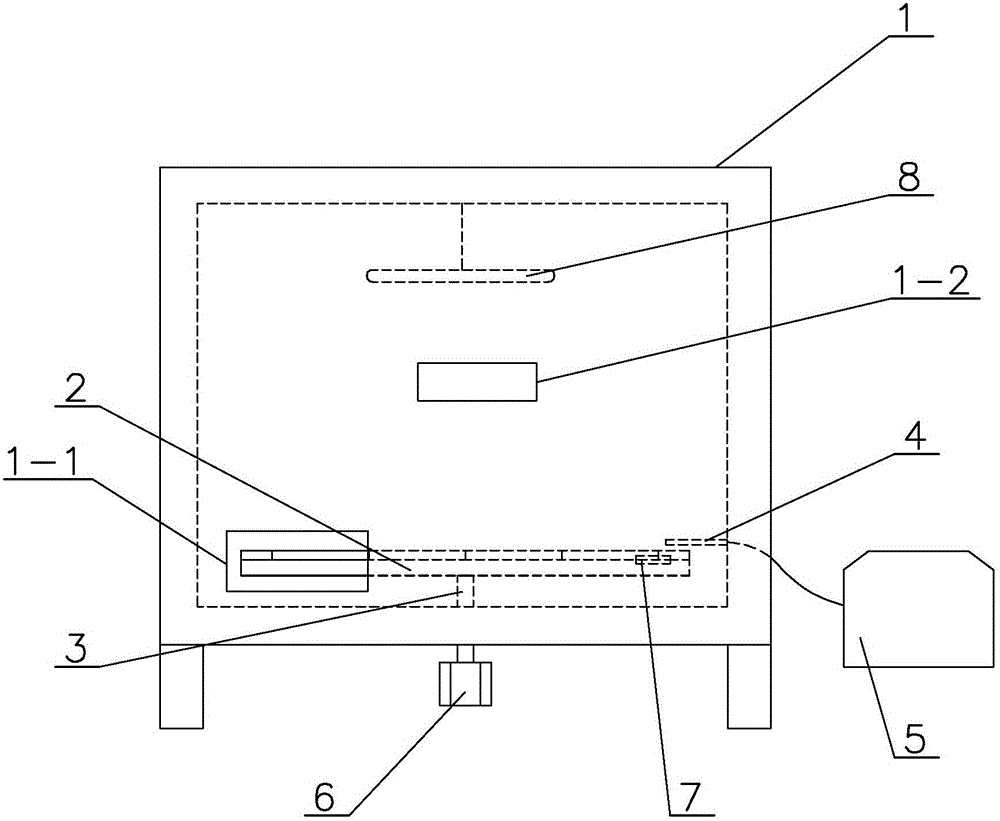

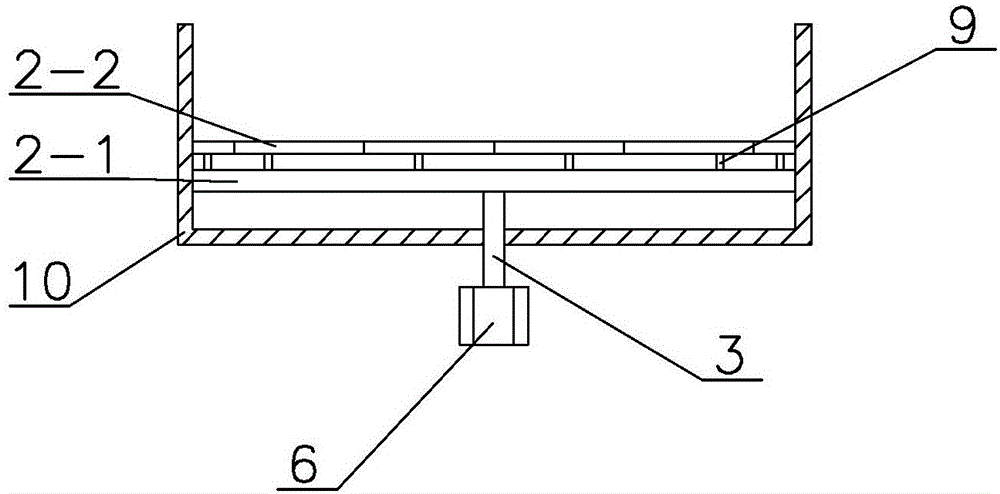

[0027] Embodiment 1: Combining figure 1 Describe this embodiment, this embodiment includes an environmental chamber 1, a composite turntable 2, a transmission shaft 3, a temperature sensor 4, a data acquisition and control system 5, a drive motor 6, an ultraviolet radiation meter 7 and at least one ultraviolet light source 8, the The composite turntable 2 is arranged in the environmental chamber 1, and the composite turntable 2 includes a main turntable 2-1, and the at least one ultraviolet light source 8 is arranged directly above the main turntable 2-1, and the main turntable 2-1 The bottom surface of the drive shaft 3 is fixedly connected to one end of the drive shaft 3, and the other end of the drive shaft 3 is connected to the output shaft of the drive motor 6. A plurality of asphalt test pieces are placed on the main rotating disk 2-1, and the ultraviolet radiation meter 7 The ultraviolet probe is arranged on the disk surface of the main rotating disk 2-1, the reading ...

specific Embodiment approach 2

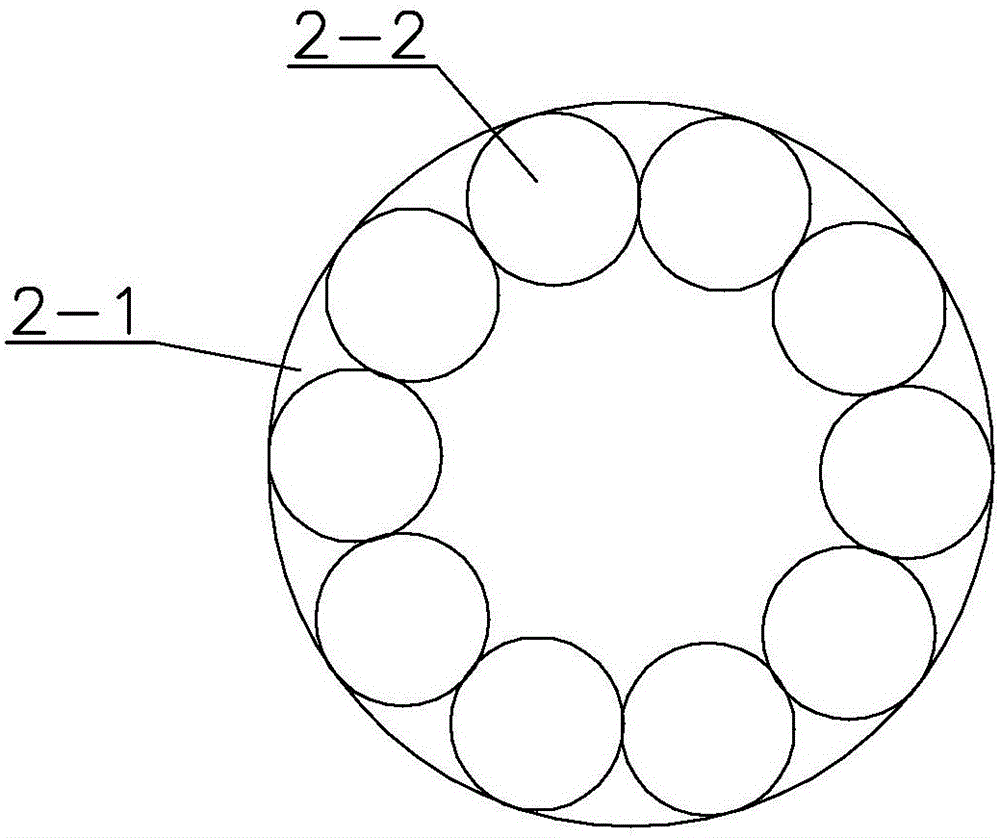

[0029] Specific implementation mode 2: Combining figure 1 and figure 2 Describe this embodiment, the composite turntable 2 in this embodiment also includes a plurality of auxiliary turntables 2-2, and a plurality of auxiliary turntables 2-2 are evenly distributed on the main turntable 2 along the circumferential direction of the main turntable 2-1 On the disk surface of -1, an asphalt test piece is placed in each auxiliary rotating disk 2-2.

[0030] In this embodiment, each auxiliary rotating disk 2-2 is provided with a vessel for holding asphalt test pieces, and the vessel can facilitate the cleaning work after the test and avoid contamination of the composite rotating disk 2. Other structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation three: combination figure 1 Describe the present embodiment, in the present embodiment, ultraviolet light source 8 is a high-pressure mercury lamp, and when the quantity of at least one ultraviolet light source 8 is one, ultraviolet light source 8 is positioned at the center directly above main rotating disk 2-1; When at least one ultraviolet light source When the number of 8 is multiple, a plurality of ultraviolet light sources 8 are evenly distributed directly above the plurality of secondary rotating disks 2-2; An ultraviolet light source 8 is arranged directly above each auxiliary rotating disk 2-2.

[0032] In this embodiment, the specific arrangement process in which the UV light sources 8 are evenly distributed directly above the plurality of auxiliary rotating disks 2-2 is as follows: the plurality of auxiliary rotating disks 2-2 are evenly distributed on the surface of the main rotating disk 2-1, The centers of circles of the pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com