Adhesive coating rubber material for high temperature resistant canvas conveyer and use method thereof

A technology for rubber materials and conveyor belts, applied in the direction of non-polymer adhesive additives, non-polymer organic compound adhesives, conveyors, etc., can solve the problem of poor resistance to heat, oxygen and air aging, and delamination of rubber and canvas , reduce service life and other issues, to achieve the effect of improving heat resistance, high temperature resistance, and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

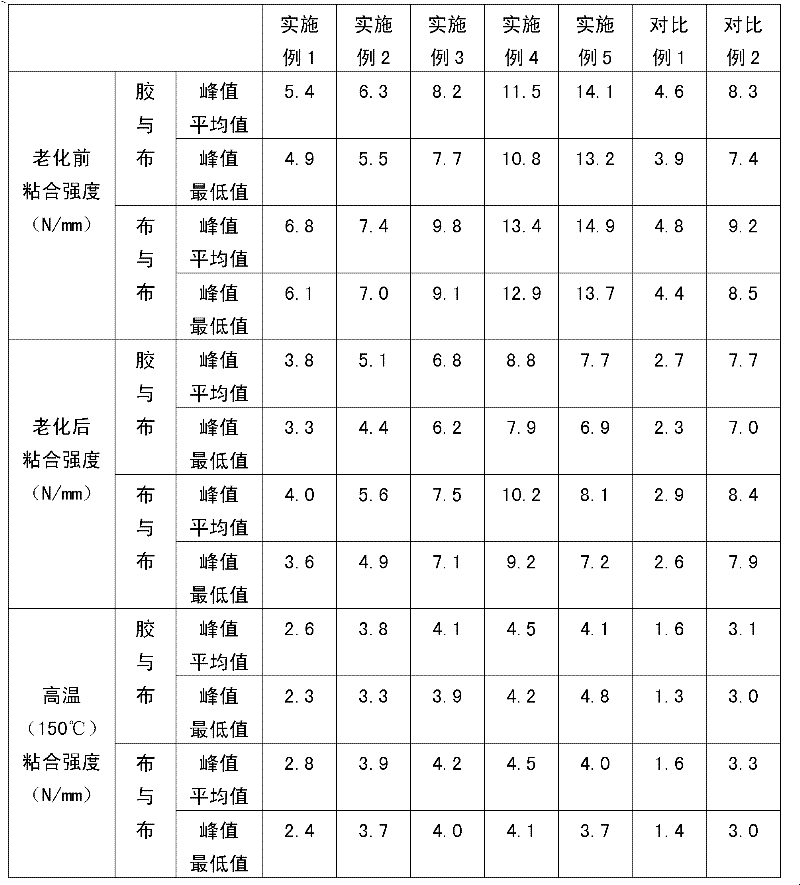

Examples

Embodiment 1

[0030] On the double-roll mill, add 500g EPDM rubber (commercially available EPDM2504) for mastication, and then add activators in sequence: 20g nano-zinc oxide (10-100nm), 10g nano-magnesium oxide (10-100nm) and stearin Acid 5g, antioxidant: N-4 (anilinophenyl) maleimide (MC) 10g, 2-mercaptobenzimidazole (MB) 5g, unsaturated carboxylic acid metal salt: magnesium methacrylate 25g, carbon Black N550 300g, plasticizer: low molecular weight (number average molecular weight is 1300) polybutadiene 50g, finally add cross-linking agent and assistant cross-linking agent: dicumyl peroxide (DCP) 10g and triallyl isotriene Polycyanate (TAIC) 5g is mixed on an open mill to obtain a rubber compound. The compounded rubber and the cloth layer go through a two-roll or four-roll calender at room temperature to complete the lamination of the adhesive glue and the cloth layer, and then pass through the forming calendering device with the EPDM covering rubber, and then vulcanize on the forming vu...

Embodiment 2

[0032] On the double-roll mill, add 500g EPDM rubber (commercially available EPDM2504) for mastication, and then add activators in sequence: 20g nano-zinc oxide (10-100nm), 10g nano-magnesium oxide (10-100nm) and stearin Acid 5g, antioxidant: N-4 (anilinophenyl) maleimide (MC) 10g, 2-mercaptobenzimidazole (MB) 5g, unsaturated carboxylic acid metal salt: magnesium methacrylate 50g, carbon Black N550 200g, white carbon black 100g, plasticizer: low molecular weight (number average molecular weight 1300) polyisobutylene 100g, finally add cross-linking agent and auxiliary cross-linking agent: dicumyl peroxide (DCP) 10g and triallyl Isocyanuric acid ester (TAIC) 5g, mixes on the open mill and obtains rubber compound. The compounded rubber and the cloth layer go through a two-roll or four-roll calender at room temperature to complete the lamination of the adhesive glue and the cloth layer, and then pass through the forming calendering device with the EPDM covering rubber, and then vu...

Embodiment 3

[0034] On the double-roll mill, add 500g EPDM rubber (commercially available EPDM2504) for mastication, and then add activators in sequence: 20g nano-zinc oxide (10-100nm), 20g nano-magnesium oxide (10-100nm) and stearin Acid 5g, antioxidant: N-4 (anilinophenyl) maleimide (MC) 10g, 2-mercaptobenzimidazole (MB) 5g, unsaturated carboxylic acid metal salt: zinc methacrylate 50g, N550 100g, white carbon black 200g, plasticizer: low molecular weight (number average molecular weight 1300) polyisobutylene 150g, finally add cross-linking agent and co-cross-linking agent: dicumyl peroxide (DCP) 10g and triallyl isobutylene Cyanuric acid ester (TAIC) 5g is mixed on the open mill to obtain the rubber compound. The compounded rubber and the cloth layer go through a two-roll or four-roll calender at room temperature to complete the lamination of the adhesive glue and the cloth layer, and then pass through the forming calendering device with the EPDM covering rubber, and then vulcanize on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com