Polyester having thermal ageing resistant performance and production method thereof

A technology of anti-heat aging and production method, which is applied in the field of polyester and its production, can solve the problems of performance deterioration and loss of use value, and achieve the effects of good flame retardancy and excellent heat aging resistance

Active Publication Date: 2011-06-15

东莞市东翔塑胶有限公司

View PDF1 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As we all know, plastic is a material that is relatively easy to age. During use, the quality and service life of plastic parts are closely related to the aging of plastics. When aging occurs, its performance will gradually deteriorate until it eventually loses use value

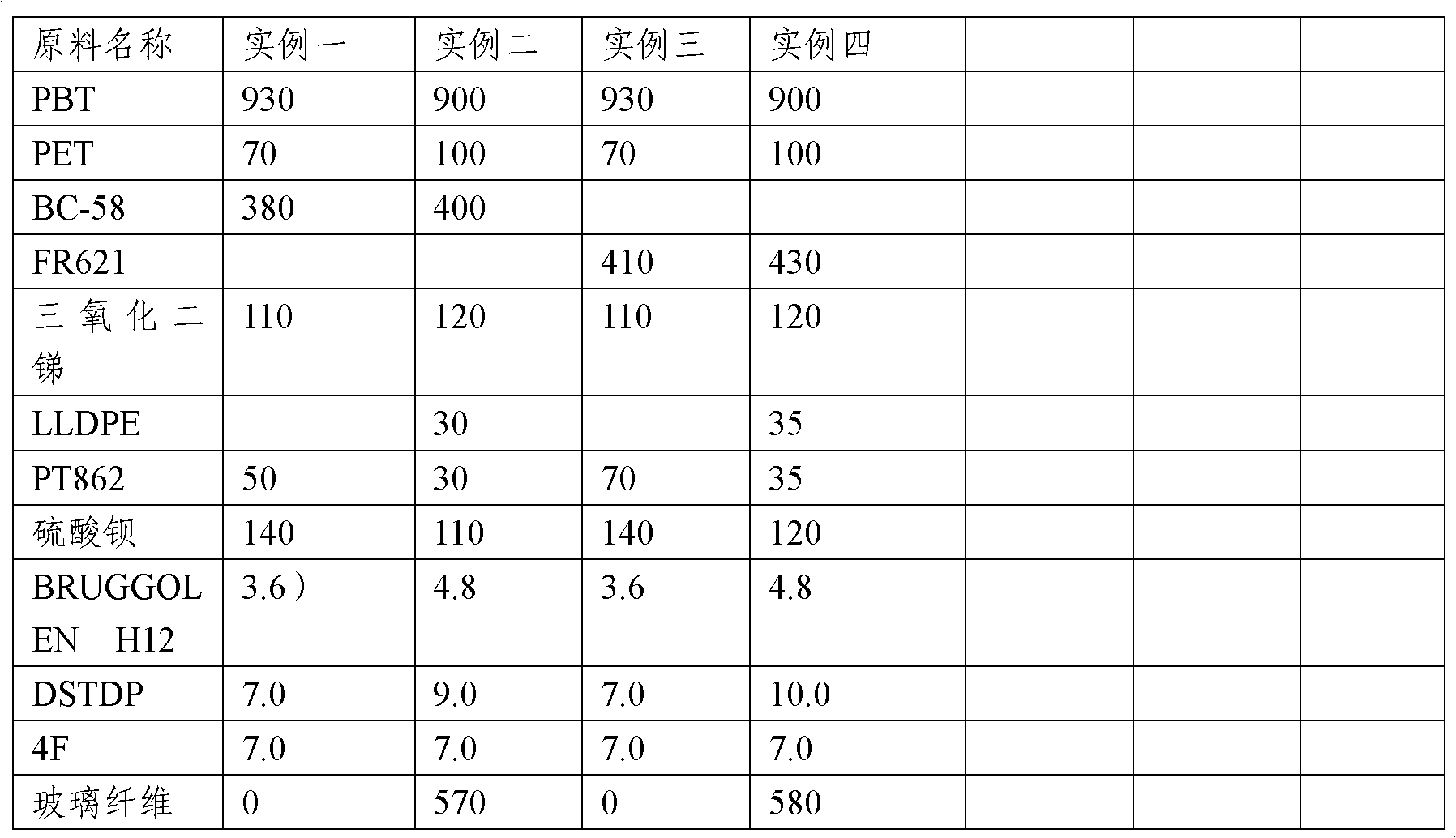

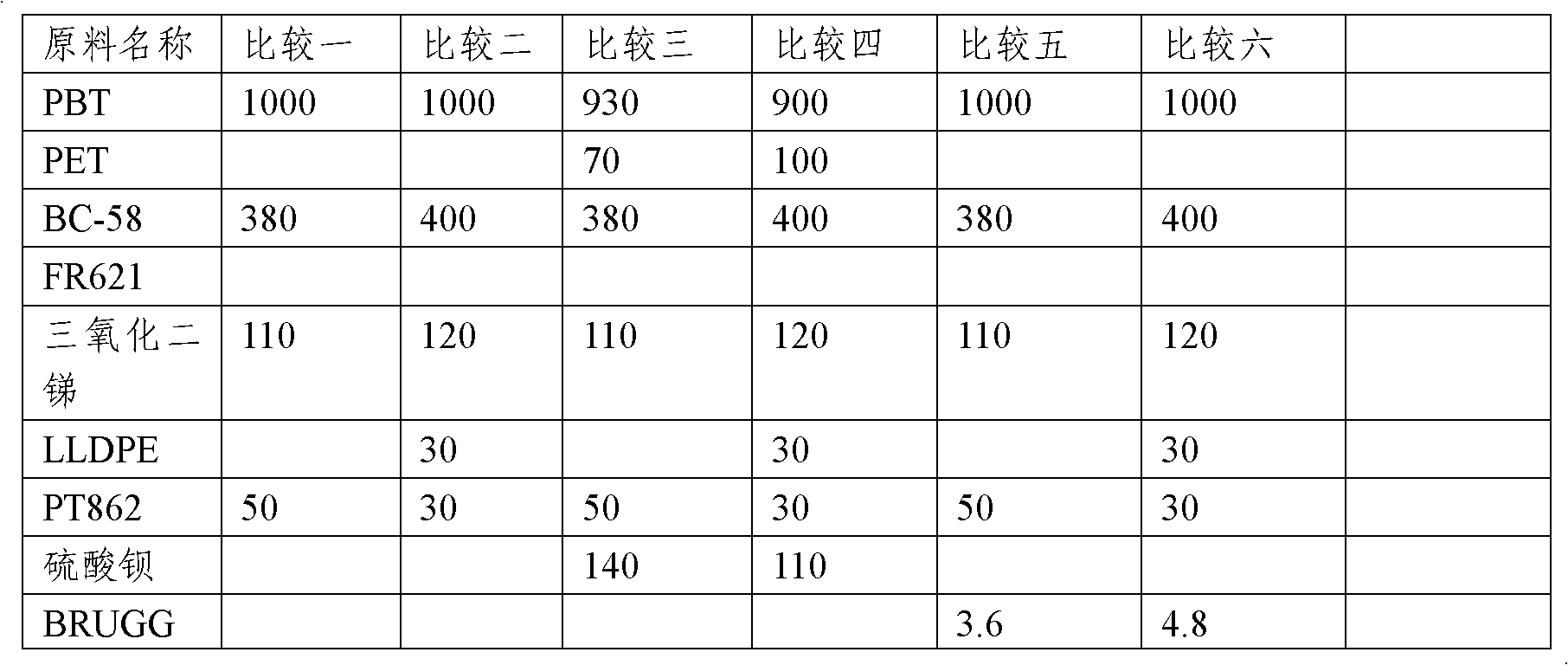

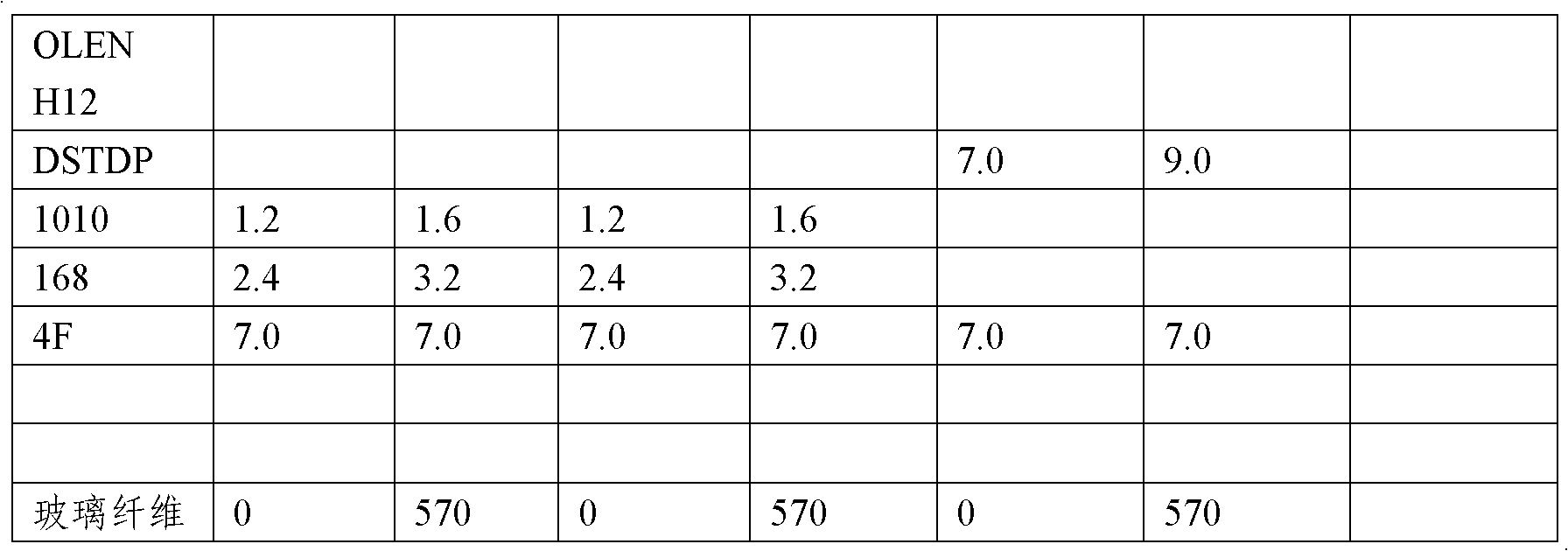

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses polyester having thermal ageing resistant performance, which comprises a thermoplastic polyester, a flexibilizer, antioxygen, a heat stabilizer, a filler and other assistant. The product has high thermal ageing resistant performance and high flame-retarding performance.

Description

Polyester with thermal aging resistance and production method thereof technical field The present invention relates to a kind of polyester and its production method. Background technique Reinforced flame retardant (non-flame retardant) polyesters are widely used in the electronics, appliances and automotive industries due to their good mechanical and electrical properties, making them ideal materials for components in these industries. As we all know, plastic is a material that is relatively easy to age. During use, the quality and service life of plastic parts are closely related to the aging of plastic. When aging occurs, its performance will gradually deteriorate until it eventually loses use value. The aging of plastics is mainly manifested in the following forms, such as cracking, stickiness, hardening, softening, pulverization, discoloration, and mold growth. In daily life, reinforced flame retardant (non-flame retardant) polyester materials play a key role in the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L67/00C08L67/02C08K13/04C08K7/14C08K13/02C08K3/30C08K5/13C08K5/524C08K13/06C08K9/06B29B9/06B29C47/92B29C48/92

CPCB29C48/40B29C48/92B29C2948/9259B29C2948/92704B29C2948/92885

Inventor 马宝海陈哲

Owner 东莞市东翔塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com