Method for evaluating ageing life of cable insulation material for ship

A technology for insulating materials and life evaluation, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., and can solve the problems of work efficiency, cost reduction, unsatisfactory detection requirements, and long experiment cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] One, principle of the present invention

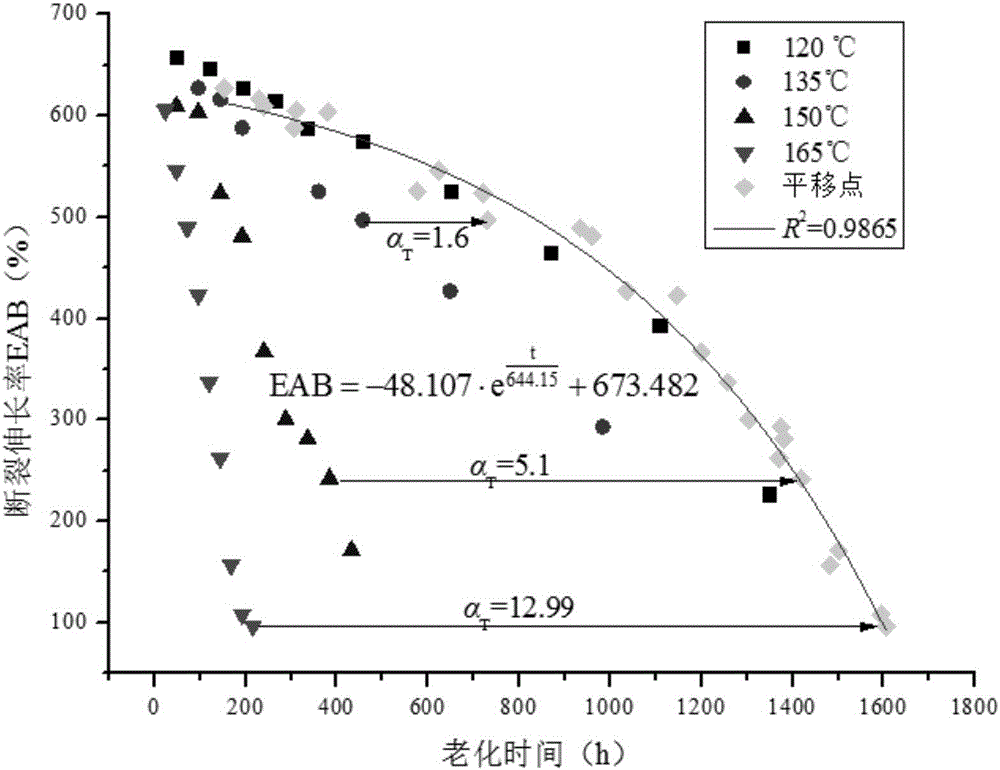

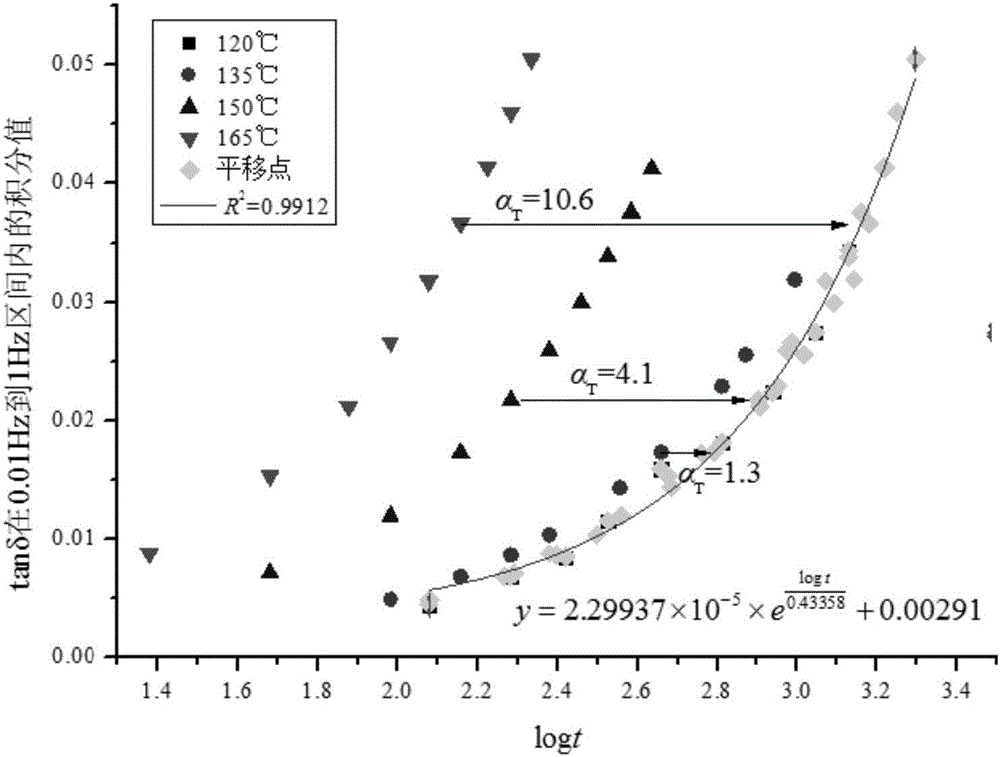

[0050] Carry out accelerated thermal aging experiments on cable insulation material samples, quickly simulate the aging process of cable insulation materials, obtain the elongation at break values at different aging times and aging temperatures, and shift the curve by time-temperature shift algorithm, and use the shift factor Find the activation energy. The current internationally recognized elongation at break is reduced to 50% of the initial value as the end-of-life indicator, and the cable life equation based on elongation at break is obtained.

[0051] The equation for the translation curve should have the following form:

[0052] EAB=-Aexp(t / B)+C (1)

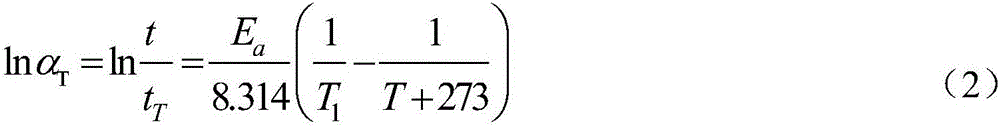

[0053] The life extrapolation equation should have the following form:

[0054]

[0055] In the formula: EAB is the elongation at break, t is the accelerated thermal aging time of insulating materials; A, B, C are coefficients related to material aging, t T is the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com