Method for evaluating residual service life of marine low-pressure rubber-insulated cable

An insulated cable, life-span technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of lack of standards and criteria, good accessibility, and no data of engineering value can be retrieved, so as to save evaluation time and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail by taking an example of assessing the remaining life of an unreplaced backbone cable of a ship that has sailed for 40 years. The detailed parameters of the cable are shown in Table 2.

[0031] Table 2 Parameters of a ship's main cable

[0032]

Length (m)

Number of cores

Specification

(mm 2 )

insulation

Outer sheath

Laid

time cable

model 10 1 185 Ethylene Propylene Rubber Neoprene 40 years CEF

[0033] (1) Cable life equation based on elongation at break of cable insulation material

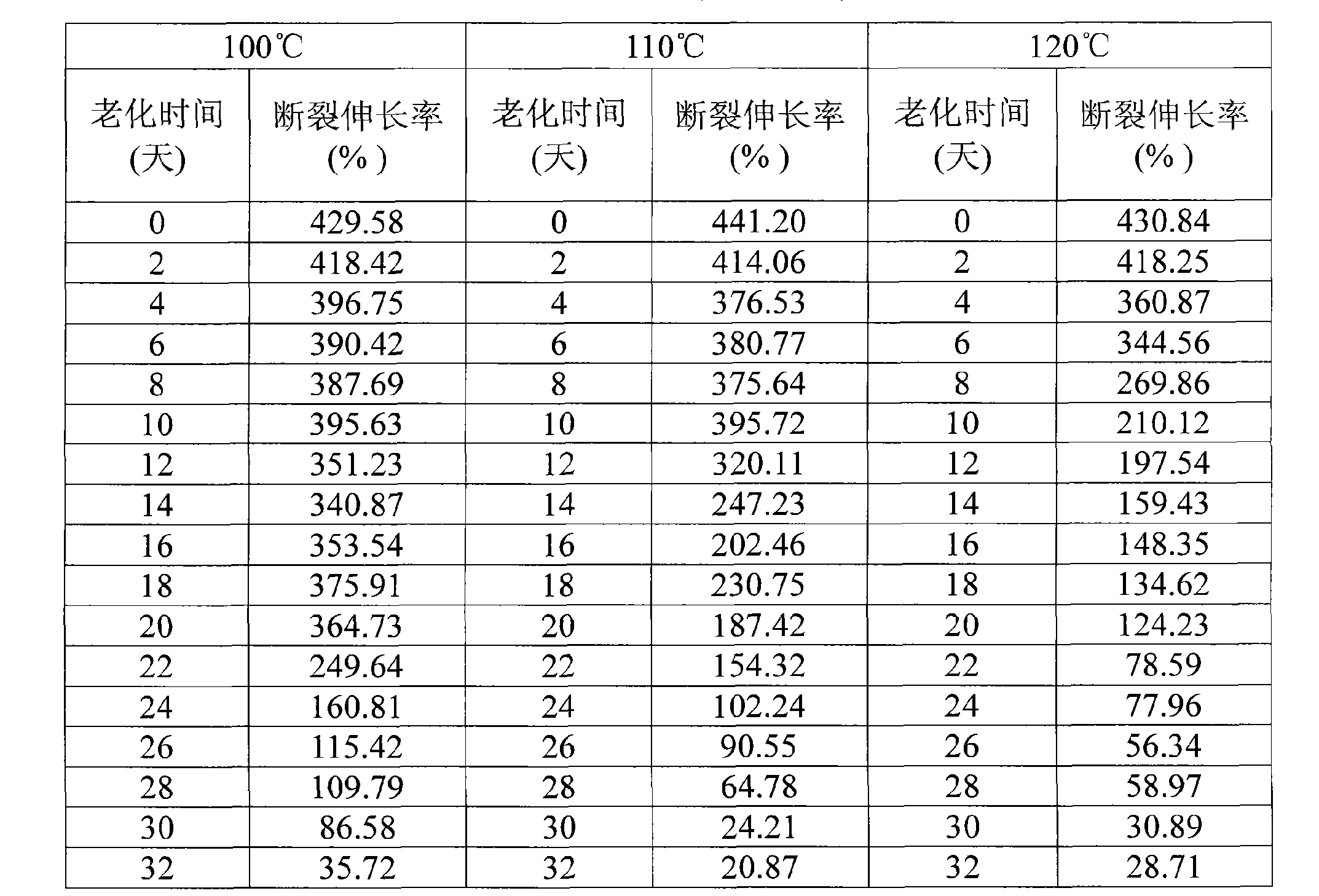

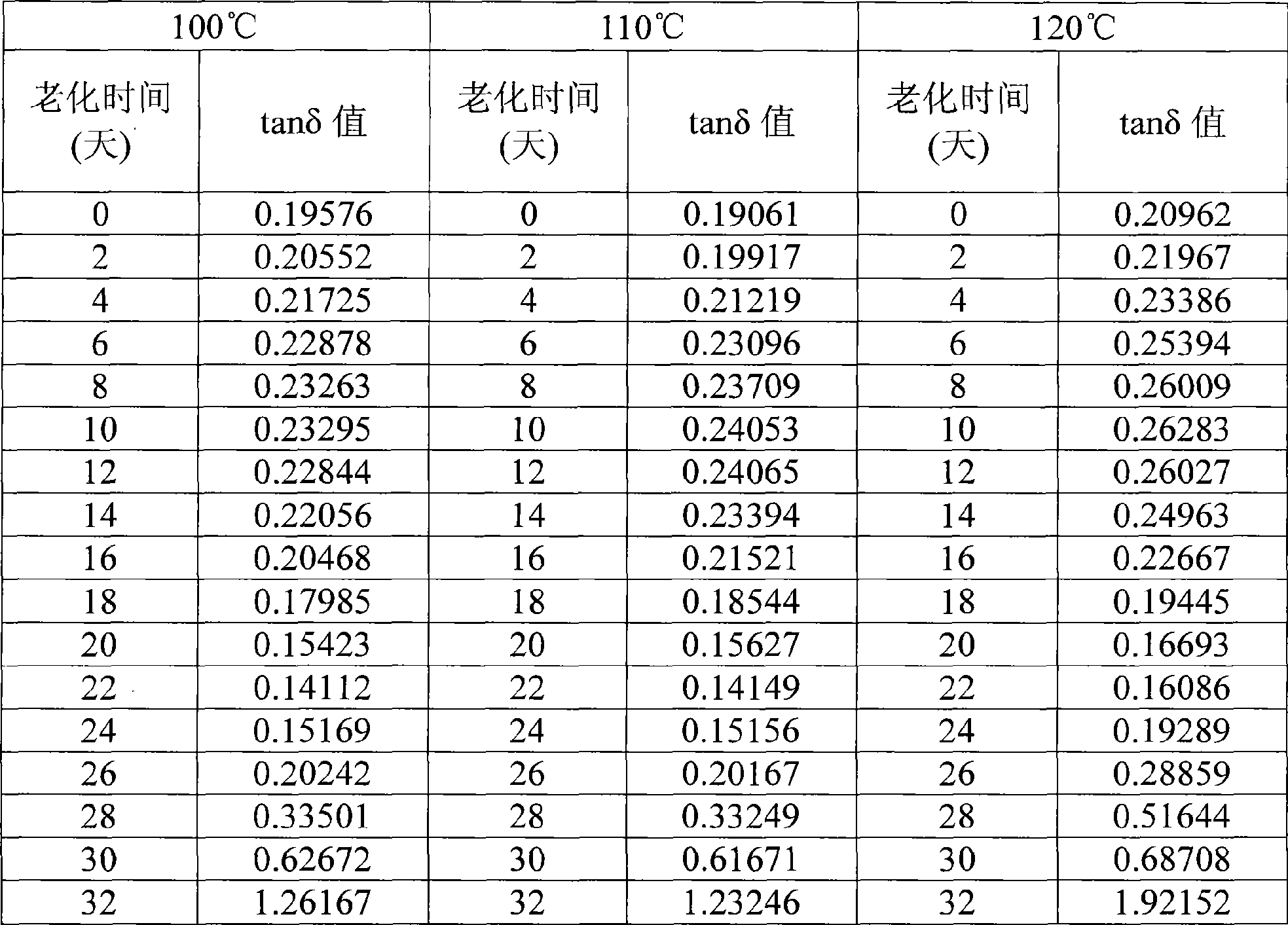

[0034] Accelerated thermal aging test is carried out on the insulation material of the cable, ethylene propylene rubber. The rated operating temperature of the cable is 85°C, and the stable temperature of the accelerated thermal aging test is selected as 100°C, 110°C, and 120°C. The test results of elongation at break of cable insulation materials are sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com